Preparation method for CrN coating on surface of nuclear zirconium alloy and product

A technology of zirconium alloy and coating, which is applied in the field of preparation technology of high-thickness CrN coating, can solve the problems of poor bonding force between coating and zirconium alloy, poor corrosion resistance, etc. The effect of bombardment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

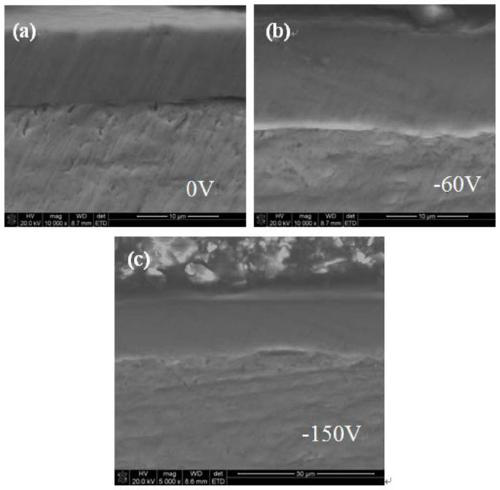

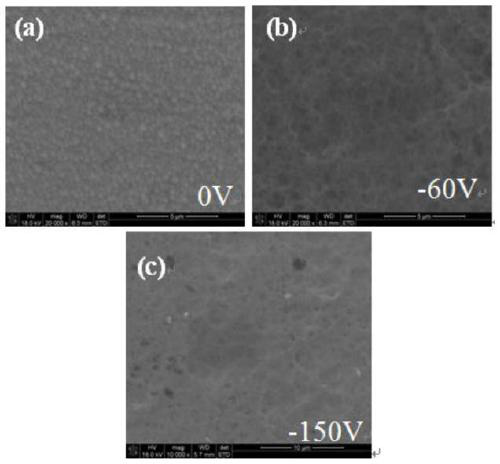

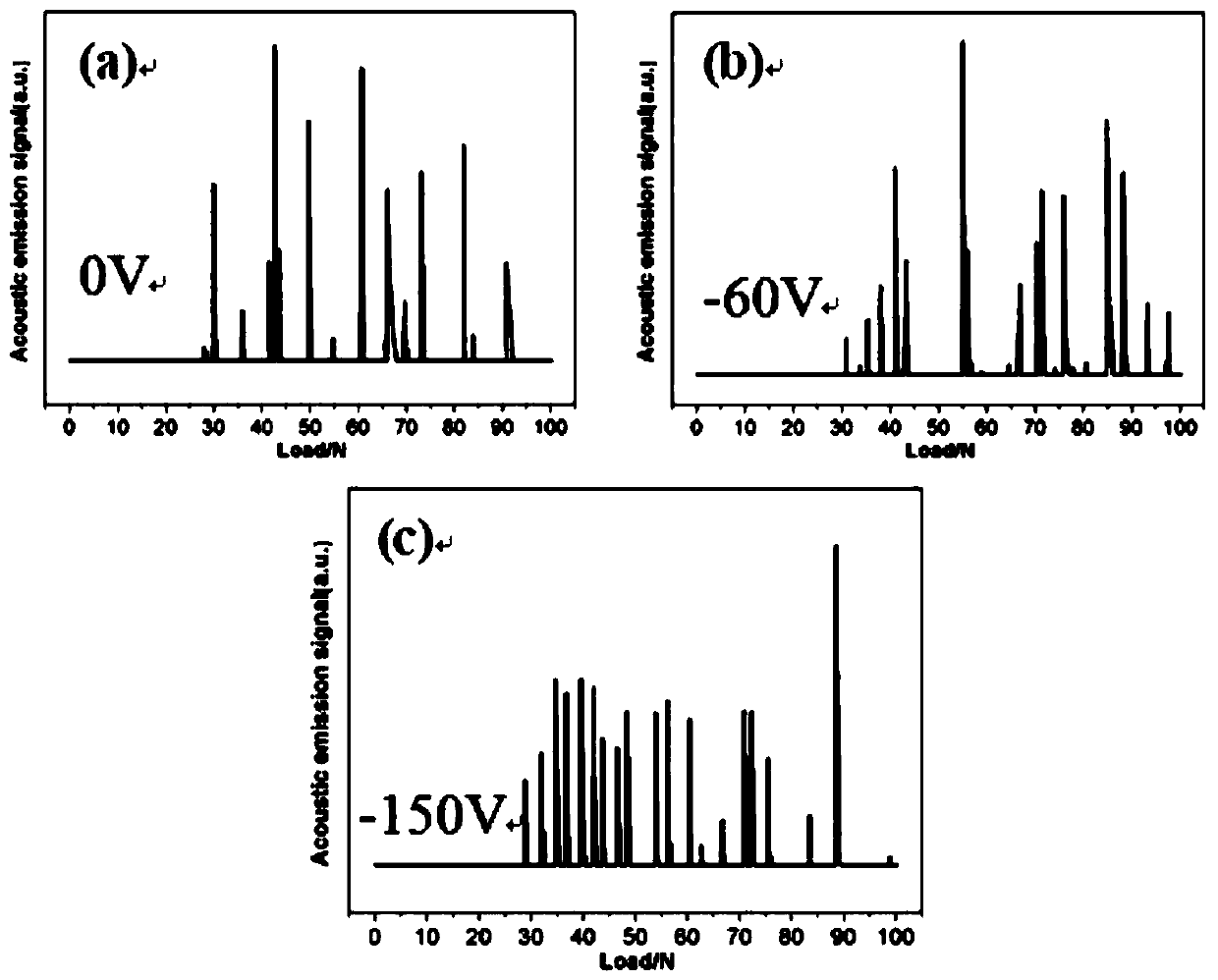

[0030] In this embodiment, the CrN coating deposited on the surface of the Zr-4 alloy substrate adopts ultra-high vacuum multi-target co-sputtering technology. 2 The purity is 99.999%, and the specific preparation process includes the following steps:

[0031] (1) Base material pretreatment

[0032] Process the Zr-4 alloy into a square piece with a side length of 1cm and a thickness of 3mm, and use 240 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 3000 mesh water abrasive paper to polish the Zr-4 alloy substrate in turn from coarse to fine, and then use The polishing paste was polished on a metallographic polishing machine. After polishing, it was ultrasonically cleaned with acetone and absolute ethanol for 10 minutes, and dried for use.

[0033] (2) Reverse sputtering cleaning of substrate materials

[0034] Place the pretreated substrate material on the sample stage in the vacuum furnace cavity of the magnetron sputtering equipment, and vacuum the vacuum furnace cavity to 2×10...

Embodiment 2

[0042] In this embodiment, the CrN coating deposited on the surface of the Zr-4 alloy substrate adopts ultra-high vacuum multi-target co-sputtering technology. 2 The purity is 99.999%, and the specific preparation process includes the following steps:

[0043] (1) Base material pretreatment

[0044] Process the Zr-4 alloy into a square piece with a side length of 1cm and a thickness of 3mm, and use 240 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 3000 mesh water abrasive paper to polish the Zr-4 alloy substrate in turn from coarse to fine, and then use The polishing paste was polished on a metallographic polishing machine. After polishing, it was ultrasonically cleaned with acetone and absolute ethanol for 15 minutes, and dried for use.

[0045] (2) Reverse sputtering cleaning of substrate material

[0046] Place the pretreated substrate material on the sample stage in the vacuum furnace cavity of the magnetron sputtering equipment, and vacuum the vacuum furnace cavity to 1×10 ...

Embodiment 3

[0054] In this embodiment, the CrN coating deposited on the surface of the Zr-4 alloy substrate adopts ultra-high vacuum multi-target co-sputtering technology. 2 The purity is 99.999%, and the specific preparation process includes the following steps:

[0055] (1) Base material pretreatment

[0056] Process the Zr-4 alloy into a square piece with a side length of 1cm and a thickness of 3mm, and use 240 mesh, 600 mesh, 1000 mesh, 1500 mesh, and 3000 mesh water abrasive paper to polish the Zr-4 alloy substrate in turn from coarse to fine, and then use The polishing paste was polished on a metallographic polishing machine. After polishing, it was ultrasonically cleaned with acetone and absolute ethanol for 20 minutes, and dried for use.

[0057] (2) Reverse sputtering cleaning of substrate material

[0058] Place the pretreated substrate material on the sample stage in the vacuum furnace cavity of the magnetron sputtering equipment, and vacuum the vacuum furnace cavity to 2×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com