Manufacturing method and special tool for double-row down jacket ornament folds

A special tool and production method technology, applied in the field of down jacket production, can solve the problems that affect the quality of clothing, the folds are difficult to be unified, and the folds are different in size, so as to reduce the number of repetitive operations and the density of folds. Uniform and easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content, features and effects of the present invention, the following examples are given to illustrate in detail the manufacturing method and special tools of the decorative pleats of the double-row down jacket of the present invention.

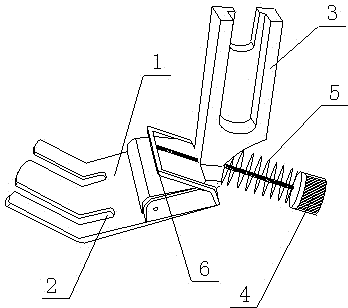

[0017] The manufacturing method and special tools of decorative pleats for double-row down jackets are characterized in that they include the following steps:

[0018] 1) The fabric to be pleated is placed on the surface fabric of the down jacket, and the pleated fabric and the surface fabric of the down jacket are superimposed on the operating table of the double needle machine;

[0019] 2) Adjust the bobbin case and thread clamp of the double needle machine to adjust the tightness of the bottom thread and the upper thread, thereby adjusting the density of the creases;

[0020] 3) Adjust the stitch length to adjust the distance of the double-row pleats;

[0021] 4) Rotate the screw shaft 4 on the presser foot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com