A kind of injection molding method of ferrite soft magnetic material

An injection molding, soft magnetic material technology, applied in grain processing and other directions, can solve the problems of low iron loss, difficult mass production, and complex shape of ferrite materials, and achieve the effects of high mechanical strength, high density, and uniform internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

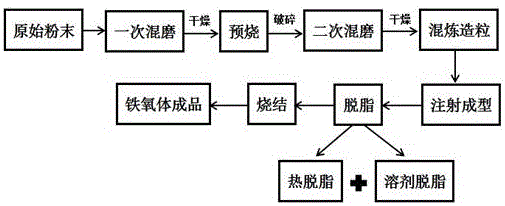

Image

Examples

Embodiment 1

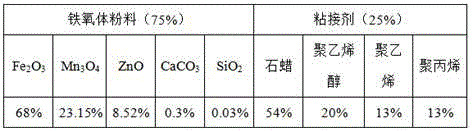

[0016] The raw materials selected in this embodiment are as shown in Table 1 by mass percentage:

[0017] Table 1

[0018]

[0019] The steps of injection molding to prepare ferrite are as follows:

[0020] (1) Powder preparation: Mix and grind the ferrite powder once, the speed of the ball mill is 200 r / min, and the ball milling time is 10 h. After drying with a spray dryer, the powder is pre-calcined at 700 ℃, and the pre-calcination time is After 2 h, the pre-calcined powder was crushed, and then mixed and milled for the second time, and the powder was ball milled to a particle size of 0.5-2 μm, and dried with a spray dryer. Among them, the primary mixed grinding and the secondary mixed grinding are all carried out by wet grinding method, adding 1 wt% dispersant, 8 wt% polyvinyl alcohol, 0.1 wt% defoamer, wherein the dispersant is composed of water and polypropylene .

[0021] (2) Mixing and granulation: After uniformly mixing the powder obtained in step 1) with the b...

Embodiment 2

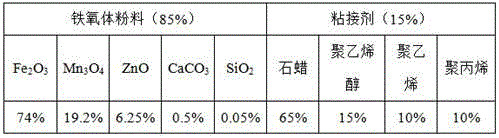

[0027] The raw materials selected in this embodiment are as shown in Table 2 by mass percentage:

[0028] Table 2

[0029]

[0030] The steps of injection molding to prepare ferrite are as follows:

[0031] (1) Powder preparation: The ferrite powder was mixed and milled once, the speed of the ball mill was 225 r / min, and the ball milling time was 12 h. After drying, the powder was pre-calcined at 800 °C for 2 h. After the pre-fired powder is crushed, it is mixed and milled for the second time, and the powder is ball-milled to a particle size of 0.5-2 μm, and then dried. Among them, the primary mixed grinding and secondary mixed grinding are carried out by wet grinding method, adding 2 wt% dispersant, 5 wt% polyvinyl alcohol, 0.15 wt% defoamer, wherein the dispersant is composed of water and polypropylene .

[0032] (2) Mixing and granulation: After uniformly mixing the powder obtained in step 1) with the binder, kneading at 150 °C for 3 hours to obtain a mixture, and cru...

Embodiment 3

[0038] The raw material that present embodiment selects is as shown in table 3 by mass percentage:

[0039] table 3

[0040]

[0041] The steps of injection molding to prepare ferrite are as follows:

[0042] (1) Powder preparation: The ferrite powder was mixed and milled once, the speed of the ball mill was 250 r / min, and the ball milling time was 14 h. After drying, the powder was pre-calcined at 900 °C for 3 h. After the pre-calcined powder is crushed, it is mixed and milled for a second time. The ball milling time is 2 h. The particle size of the powder after ball milling is 0.5-2 μm, and then it is dried. Among them, the primary mixed grinding and the secondary mixed grinding are all carried out by wet grinding method, adding 1 wt% dispersant, 8 wt% polyvinyl alcohol, 0.2 wt% defoamer, wherein the dispersant is composed of water and polypropylene .

[0043] (2) Mixing and granulation: After uniformly mixing the powder obtained in step 1) with the binder, kneading at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com