A kind of injection molding preparation method of metal magnetic powder core

A technology of injection molding and magnetic powder core, applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of complex shapes and difficult mass production, and achieve the effects of uniform density, high mechanical strength and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

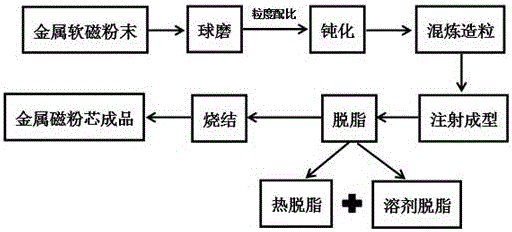

Method used

Image

Examples

Embodiment 1

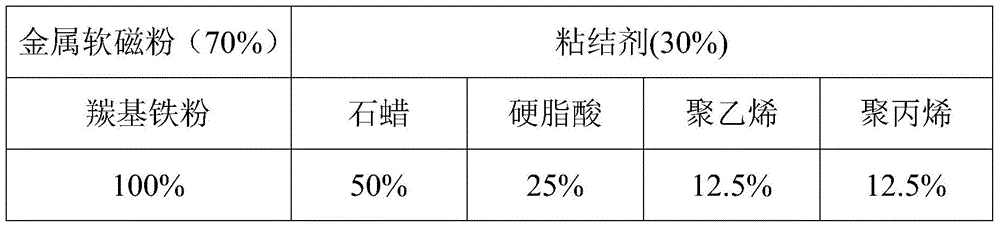

[0016] The selection and consumption of metal soft magnetic alloy powder and binding agent in the present embodiment are as shown in Table 1 (all by weight percentage):

[0017] Table 1

[0018]

[0019] The specific preparation methods include:

[0020] (1) Select carbonyl iron powder as metal soft magnetic powder, and ball mill it into powder particles with a particle size of less than 75 μm, wherein the powder particle size is 40 μm to 75 μm and accounts for 40 wt% of the total amount, and the powder particle size is less than 40 μm accounts for 60 wt% of the total amount;

[0021] (2) Add 0.4wt% phosphoric acid to the soft magnetic alloy powder prepared in step (1), use absolute ethanol as the phosphoric acid dispersant, mix well, and keep warm at 80°C for 2 hours;

[0022] (3) uniformly mix the passivated soft magnetic powder and binder in step 2, knead at 100°C for 3 hours to obtain a mixture, and crush the mixture to particles with an average particle diameter of 8 ...

Embodiment 2

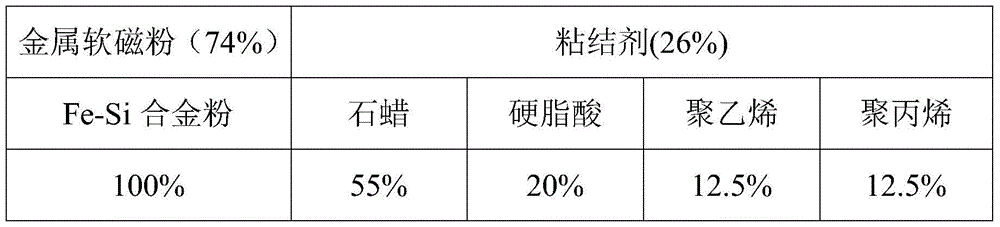

[0028] The selection and consumption of metal soft magnetic alloy powder and binding agent in the present embodiment are as shown in Table 2 (all by weight percentage):

[0029] Table 2

[0030]

[0031] The specific preparation methods include:

[0032] (1) Ball milling the metal powder into powder particles with a particle size of less than 75 μm, wherein 40 μm to 75 μm accounts for 50 wt% of the total amount, and those less than 40 μm account for 50 wt% of the total amount;

[0033] (2) Add 0.8wt% phosphoric acid to the soft magnetic alloy powder prepared in step (1), use acetone as the phosphoric acid dispersant, mix well, and keep warm at 100°C for 1 hour;

[0034] (3) uniformly mix the passivated soft magnetic powder and the binder in step 2, knead at 120° C. for 2 hours to obtain a mixture, and crush the mixture to particles with an average particle diameter of 8 mm;

[0035] (4) Heating the pulverized mixture in step 3 to 120° C., injecting it into the mold cavity...

Embodiment 3

[0040] The selection and consumption of metal soft magnetic alloy powder and binding agent in the present embodiment are as shown in Table 3 (all by weight percentage):

[0041] table 3

[0042]

[0043] The specific preparation methods include:

[0044] (1) Ball milling into powder particles with a particle size of less than 75 μm, wherein 40 μm to 75 μm accounts for 60 wt% of the total amount, and those less than 40 μm account for 40 wt% of the total amount;

[0045] (2) Add 1.0wt% chromic acid to the soft magnetic alloy powder in the ratio of step (1), use absolute ethanol as the chromic acid dispersant, mix well, and keep warm at 100° C. for 1 hour;

[0046] (3) uniformly mix the passivated soft magnetic powder and binder in step 2, knead at 140° C. for 2 hours to obtain a mixture, and crush the mixture to particles with an average particle diameter of 8 mm;

[0047] (4) Heating the pulverized mixture in step 3 to 140° C., injecting it into the mold cavity under a pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com