Spray deposition densifying device and application thereof

A technology of spray deposition and densification, which is applied in the field of metal material processing, can solve the problems of material mechanical properties degradation, high temperature mechanical properties degradation, high cost of tube blank forming and processing, etc., to achieve fine dispersed particles and grains, increase cooling rate, shorten The effect of the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] In this embodiment, SiC is prepared by crucible mobile spray co-deposition device P / Al-8.5Fe-1.3V-1.7Si composite tube blank. The reinforced particles are made of mechanically crushed β‐SiC, with an average particle size of about 10 μm.

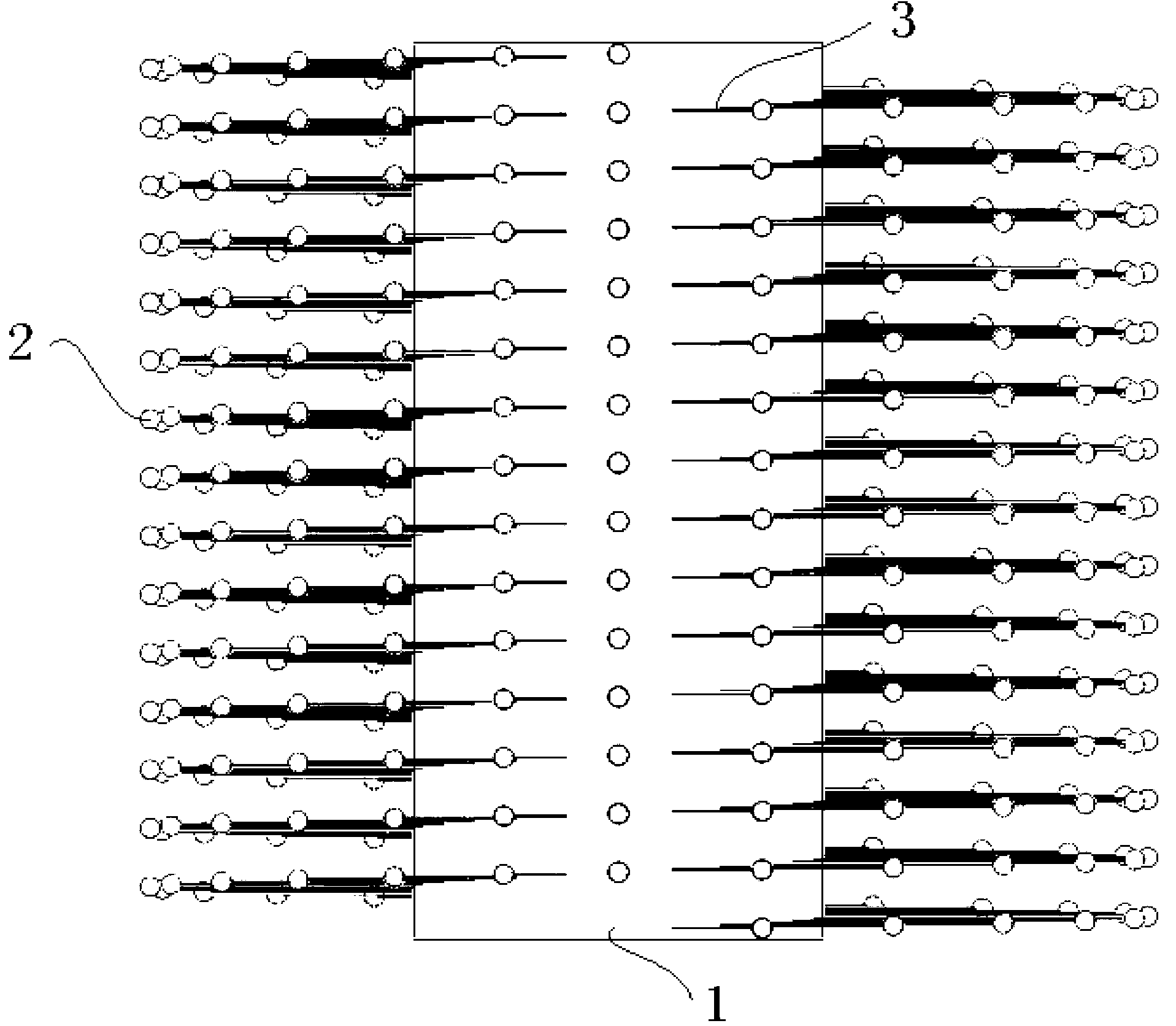

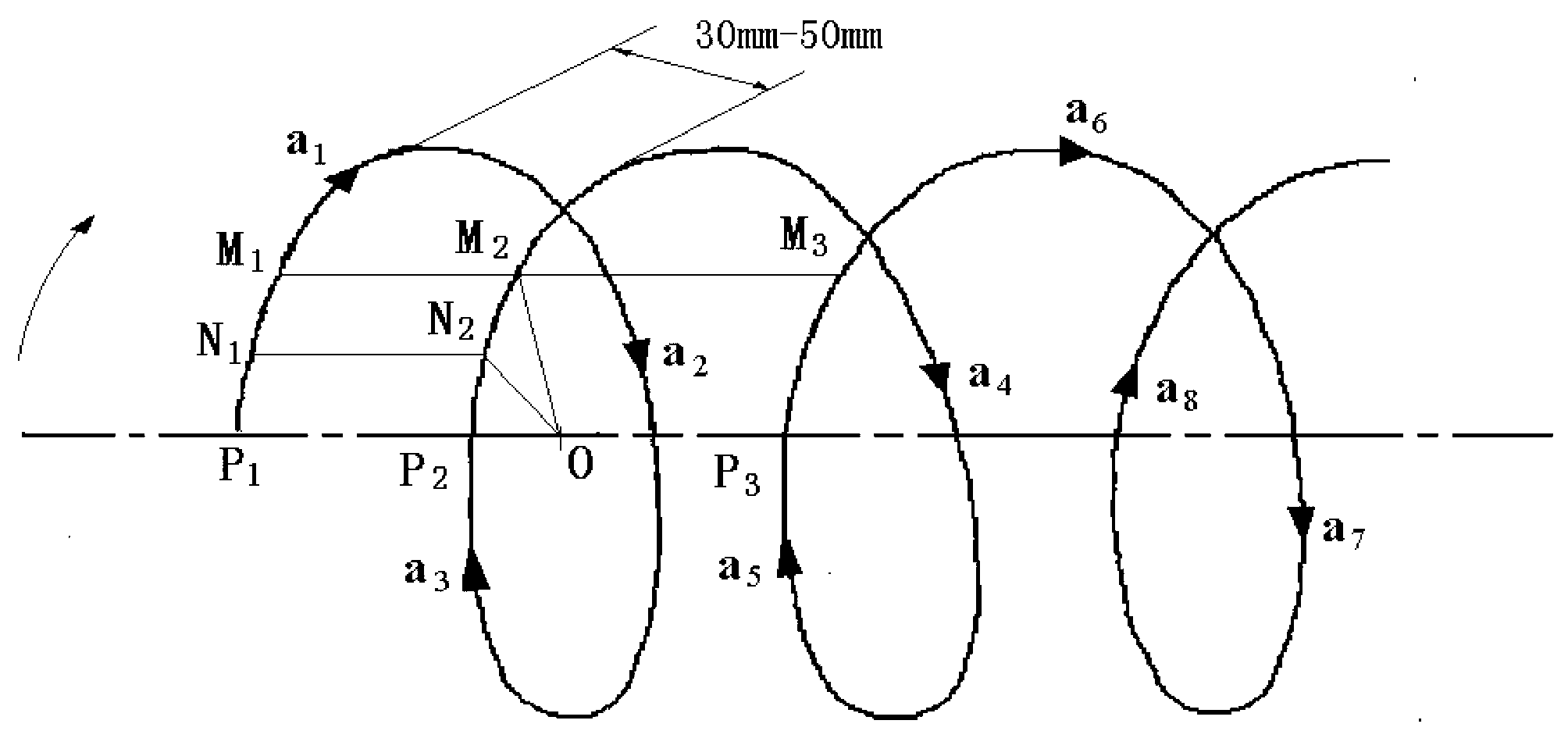

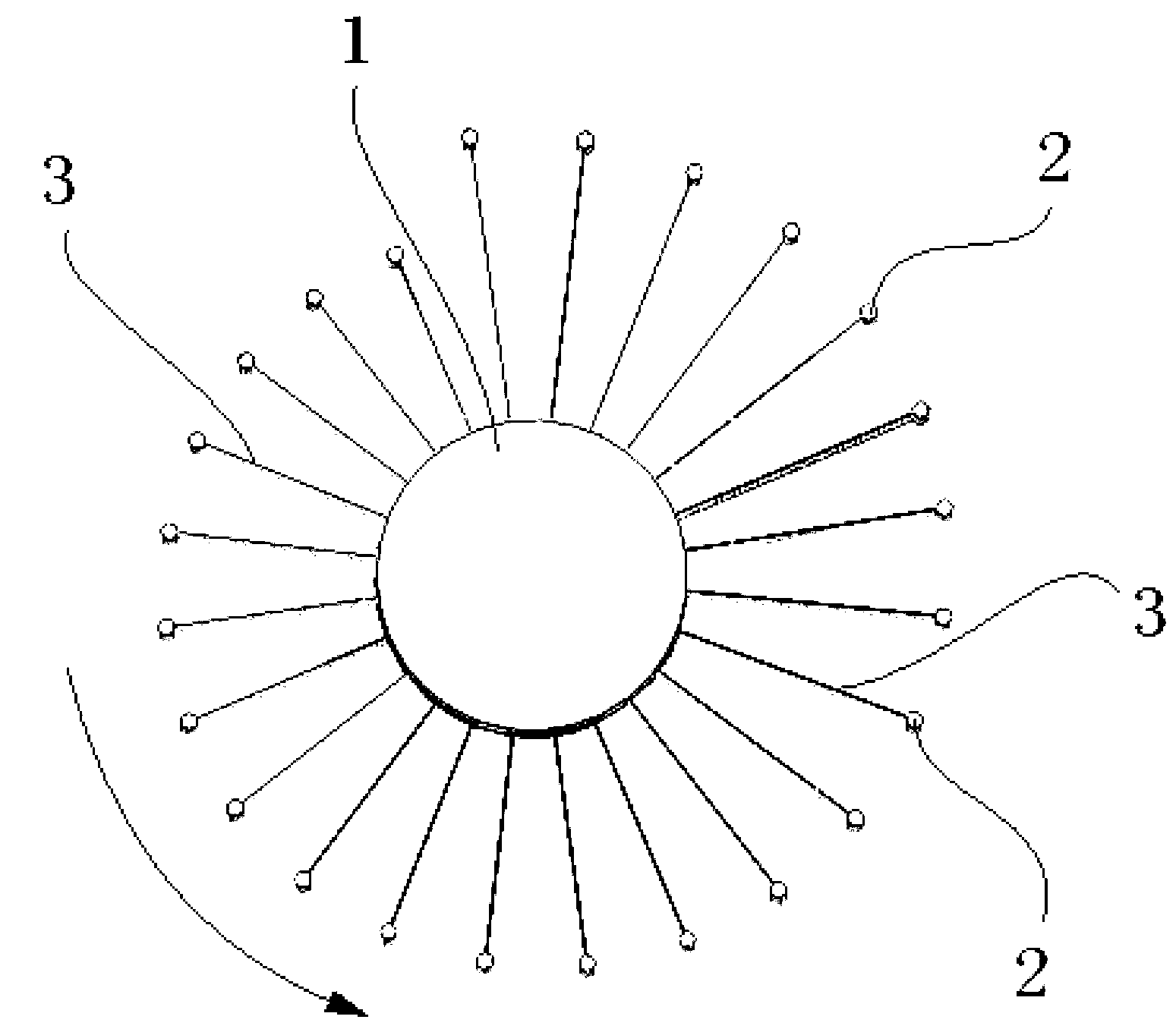

[0052] The overall structure of the equipment used in this embodiment is as follows Figure 5 As shown, it includes an atomization chamber 5, a double-circle compound atomizer 4, a metal base shaft 8 and two sets of spray-deposited densification devices 6, wherein the atomizer 4 is placed on the top of the atomization chamber 5 and is located on the metal tube blank Above the base rotating shaft 8, the base rotating shaft 8 of the metal tube blank and the densification device 6 of spray deposition are installed in the atomization chamber; The axial length of the rotating shaft is slightly greater than or equal to the axial length of the base rotating shaft of the tube base, and the rotating shaft 1 of the spray deposition densifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Central angle | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com