Method for preparing biodiesel by grease continuity ester exchange and mixing cosolvent used in method

A technology of biodiesel and co-solvent, which is applied in the direction of biofuel, biological raw material, fatty acid esterification, etc., can solve the problems of high cost and difficult separation, and achieve the effect of safe use, easy separation and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

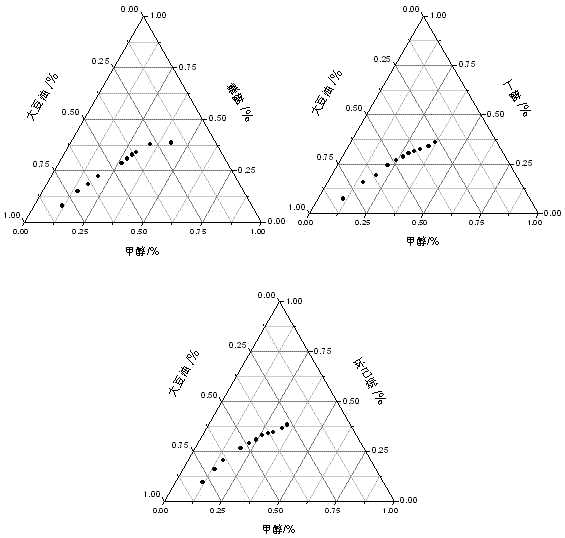

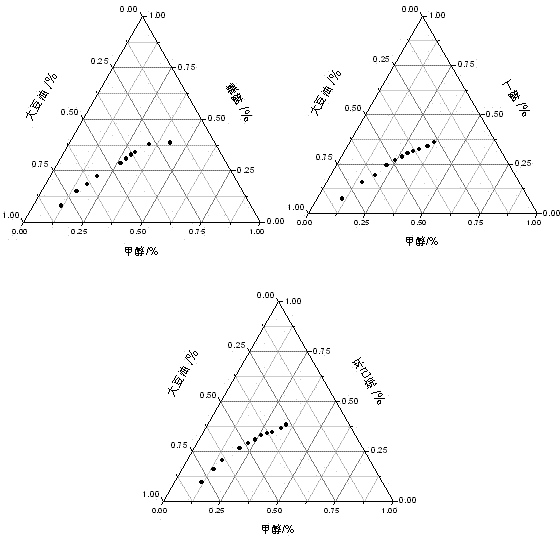

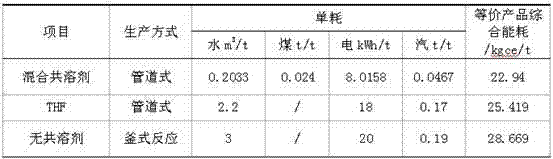

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Measure by volume percentage: 15% furfuryl alcohol, 75% butanone, and 10% n-hexane, mix them in a stirring tank, and stir at a speed of 90 rpm for 5 min to obtain a mixed co-solvent with a boiling point of 85.7°C;

[0026] Step 2: Take cottonseed oil and methanol as raw materials, KOH catalyst accounts for 1.0% of the oil mass, the alcohol-oil molar ratio is 27:1, and the co-solvent accounts for 15% of the methanol volume, mix them into a continuous tubular reactor, and control the reaction temperature at After reacting for 15 minutes at 60°C, the conversion rate of the product was measured to be 94.05%, and the kinematic viscosity (40°C) was 3.91mm 2 / s.

Embodiment 2

[0028] Step 1: Take according to the volume fraction: 15% furfuryl alcohol, 70% butanone, and 15% n-butane, mix them in a stirring tank, and stir at a speed of 90 rpm for 5 minutes to obtain a co-solvent with a boiling point of 83.2°C;

[0029] Step 2: Using soybean oil and methanol as raw materials, KOH catalyst accounts for 0.8% of the oil mass, the alcohol-oil molar ratio is 27:1, and the co-solvent accounts for 25% of the methanol volume, mix and add to the continuous tubular reactor, and control the reaction temperature at After reacting for 15 minutes at 60°C, the conversion rate of the product was measured to be 97.20%, and the kinematic viscosity (40°C) was 3.96mm 2 / s.

[0030] After GC / MS analysis, it can be known that the components corresponding to different retention times: The one with a retention time of 15.537min is methyl palmitate; The one with a retention time of 17.250min is methyl linoleate; The one with a retention time of 17.299min is methyl oleate...

Embodiment 3

[0032] Step 1: Take according to the volume fraction: 5% furfuryl alcohol, 85% acetone, and 10% isooctane, mix and place in a stirred tank, stir at a speed of 90 rpm for 5 min to obtain a co-solvent with a boiling point of 60.5°C;

[0033] Step 2: Rapeseed oil and methanol are used as raw materials, KOH catalyst accounts for 0.8% of the oil mass, the molar ratio of alcohol to oil is 25:1, and the co-solvent accounts for 26% of the methanol volume, mix and add to the continuous tubular reactor, and control the reaction temperature After reacting for 15 minutes at 60°C, the conversion rate of the product was measured to be 93.65%, and the kinematic viscosity (40°C) was 3.85mm 2 / s.

[0034] After GC / MS analysis, the components corresponding to different retention times can be obtained: The one with a retention time of 14.967min is methyl palmitate; The one with a retention time of 16.203min is methyl linoleate; The one with a retention time of 16.687min is methyl oleate; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com