Production method for solid polyferric sulphate

A production method, a technology of solid polymerization, applied in the field of water treatment, can solve the problems of no utilization, insufficient mixing, low calorific value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

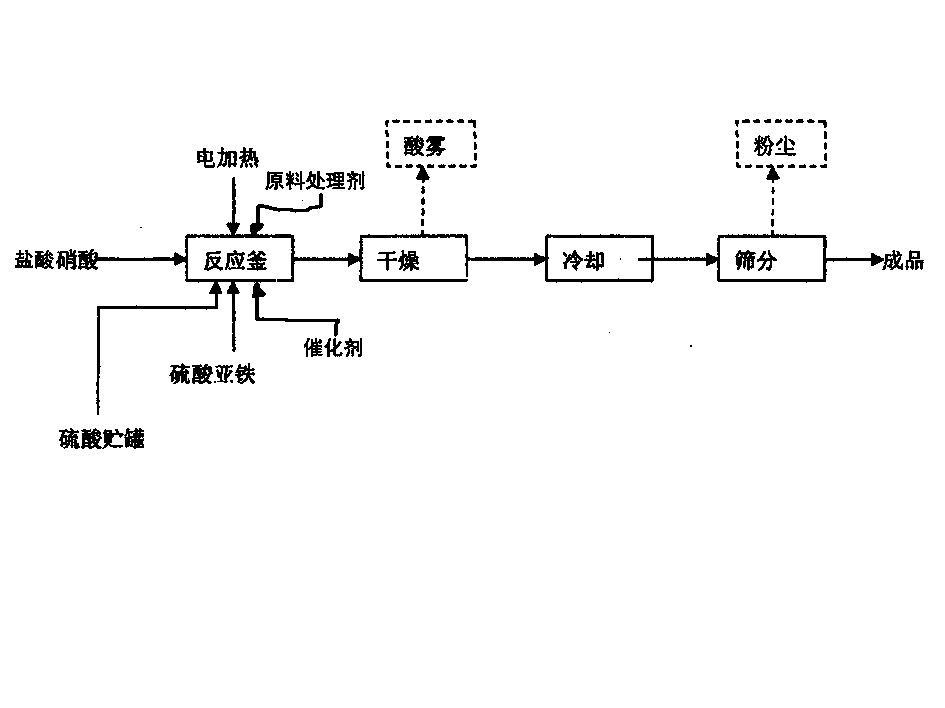

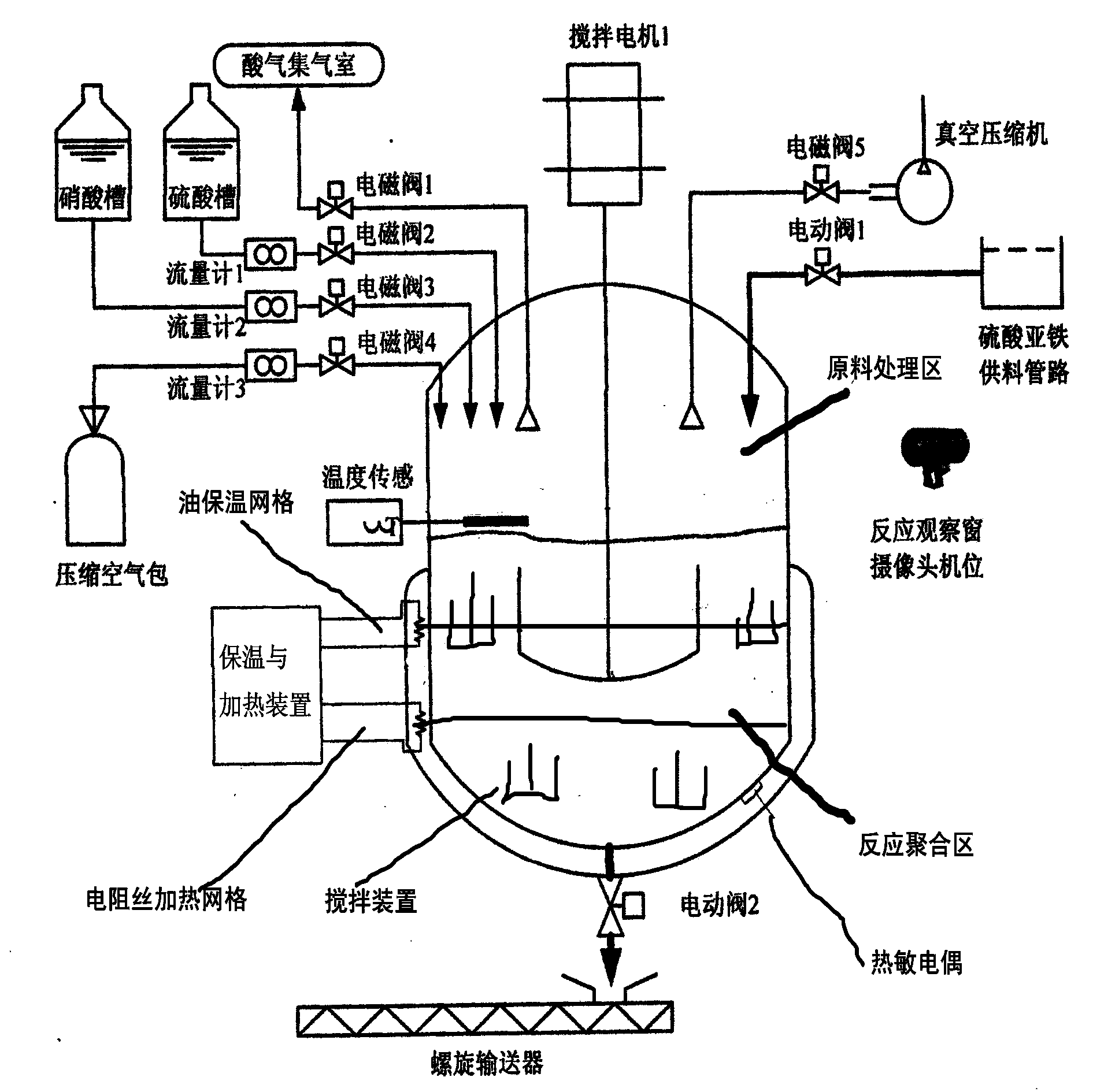

[0022] Ferrous sulfate as a raw material is mixed with 7% to 11% of solid acid (such as TiO2·H2SO4, etc.) and 1 to 2% of rare earth (such as lanthanum, cerium) and then put into the heating zone of the reactor.

[0023] The heating temperature is set at 100 to 150 degrees for the first 5 minutes, and rises to 200 degrees for the last 5 minutes.

[0024] The above mixture enters the reaction zone, where a mixture of dilute nitric acid and hydrochloric acid solution (mixing ratio of 10 to 1) has been put into the reaction zone in advance, and the ratio with ferrous sulfate as the raw material is 8%. 5 hours.

[0025] Add sulfuric acid solution and catalyst (NaClO, H2O2 (30%), KC1, etc.) in the reaction zone, the ratio of concentrated sulfuric acid solution and ferrous sulfate as raw materials is 15% to 20%, and the reaction is carried out at a constant temperature of 110 degrees, and the time for five to seven days.

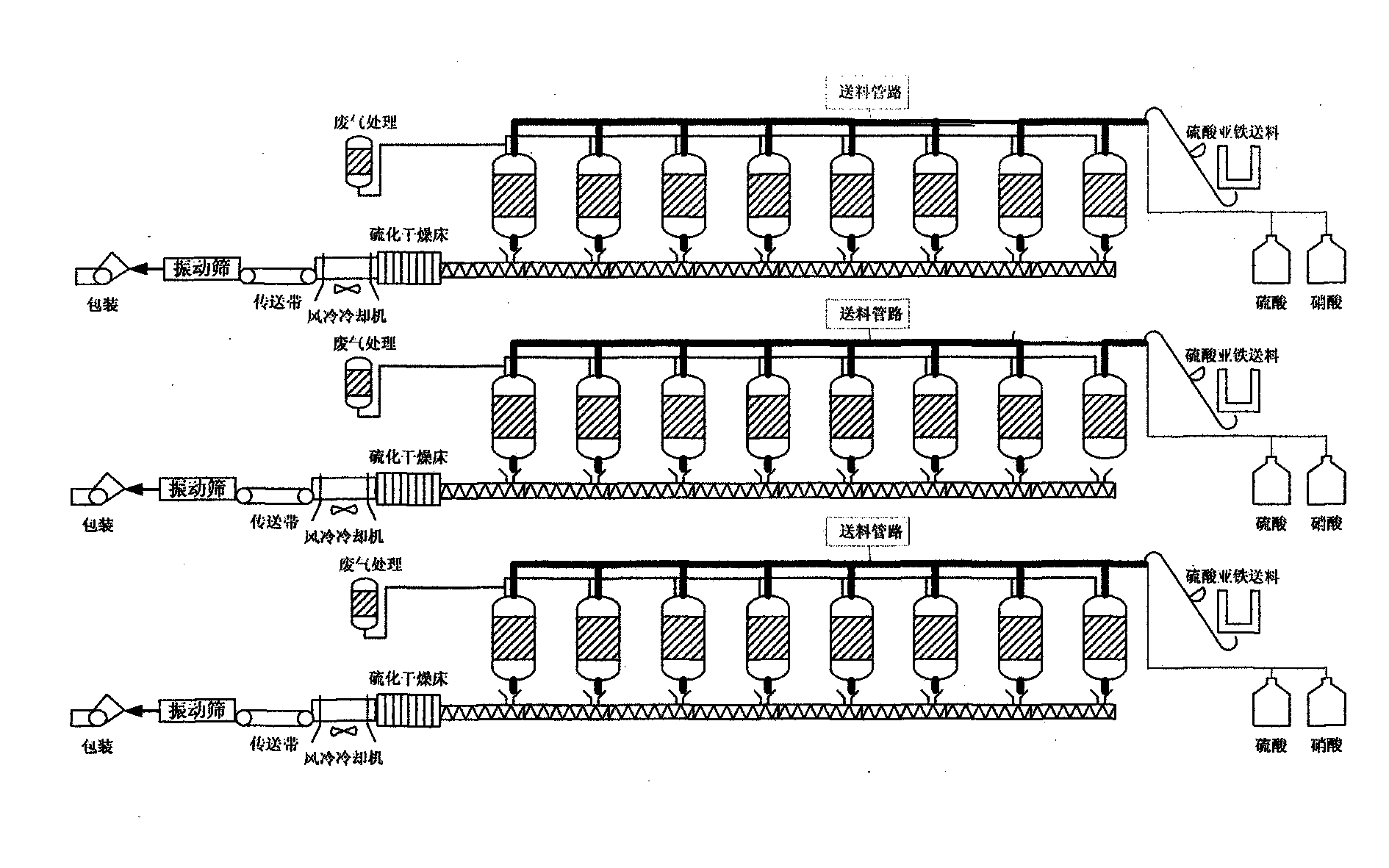

[0026] Then, it is sent to the drying room, cooling room, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com