Method for manufacturing liquid crystal display element

A technology of liquid crystal display element and manufacturing method, which is applied in nonlinear optics, instruments, optics and other directions, and can solve the problem that the orientation directions of liquid crystal molecules are not sufficiently consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0659] First, after coating the polyimide film on the ITO substrate, the polyimide film is rubbed to form an alignment film. Then, an empty liquid crystal cell (cell gap 3.5 μm) including an ITO substrate with an alignment film was produced.

[0660] Next, the liquid crystal composition is injected into the empty liquid crystal cell by a vacuum injection method.

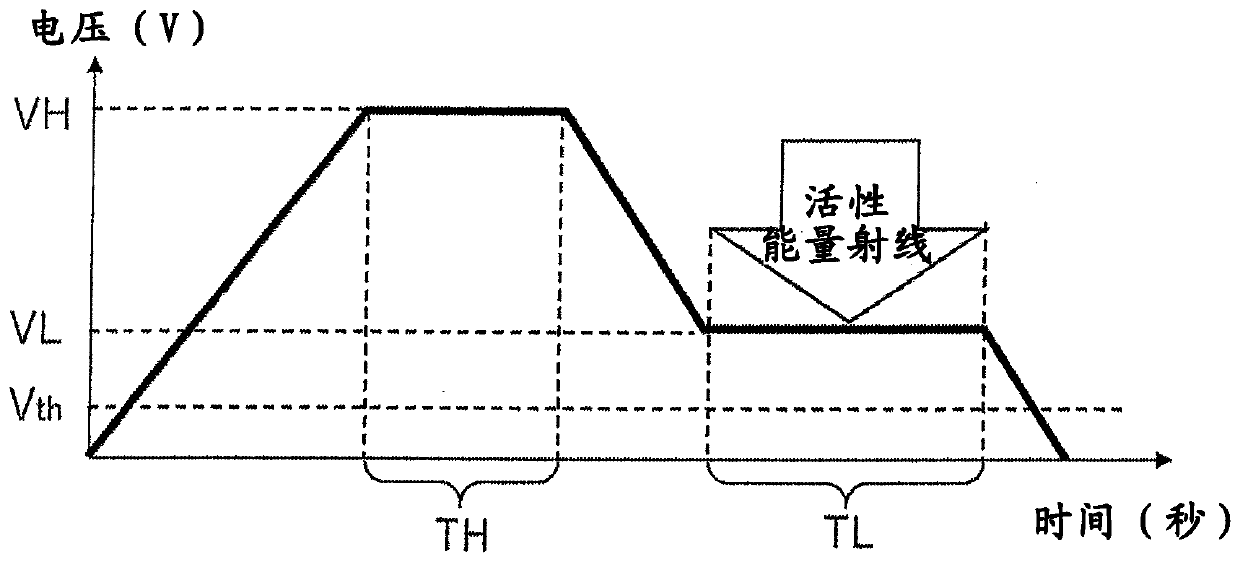

[0661] Next, to the liquid crystal cell in which the liquid crystal composition was injected, an AC voltage of 4.6 V (first voltage VH) was applied at a frequency of 100 Hz, and this state was maintained for 30 seconds. Next, the AC voltage is lowered to 4V (second voltage VL), and while maintaining this state, ultraviolet rays are irradiated through a filter that filters ultraviolet rays having a wavelength of 325 nm or less from the high-pressure mercury lamp.

[0662] At this time, the illuminance measured under the condition of the center wavelength of 365nm becomes 100mW / cm 2 Set the way to irradiate ultraviolet light...

Embodiment 2

[0664] Except for changing the first voltage VH to 6.8V, the same procedure as in Example 1 was carried out to manufacture a liquid crystal display element.

Embodiment 3

[0666] Except having changed the first voltage VH to 9.1V, the same procedure as in Example 1 was carried out to manufacture a liquid crystal display element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com