Environment-friendly rubber prefabricated track coiled material and preparation method thereof

A prefabricated and environmentally friendly technology, applied in the field of environmentally friendly rubber prefabricated track coils and their preparation, can solve the problems of poor tensile strength and elasticity, poor durability and short service life, and achieve excellent tensile strength and durability. Grinding, improving overall performance, and improving the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

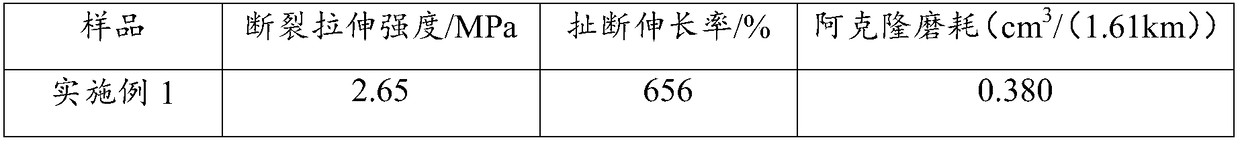

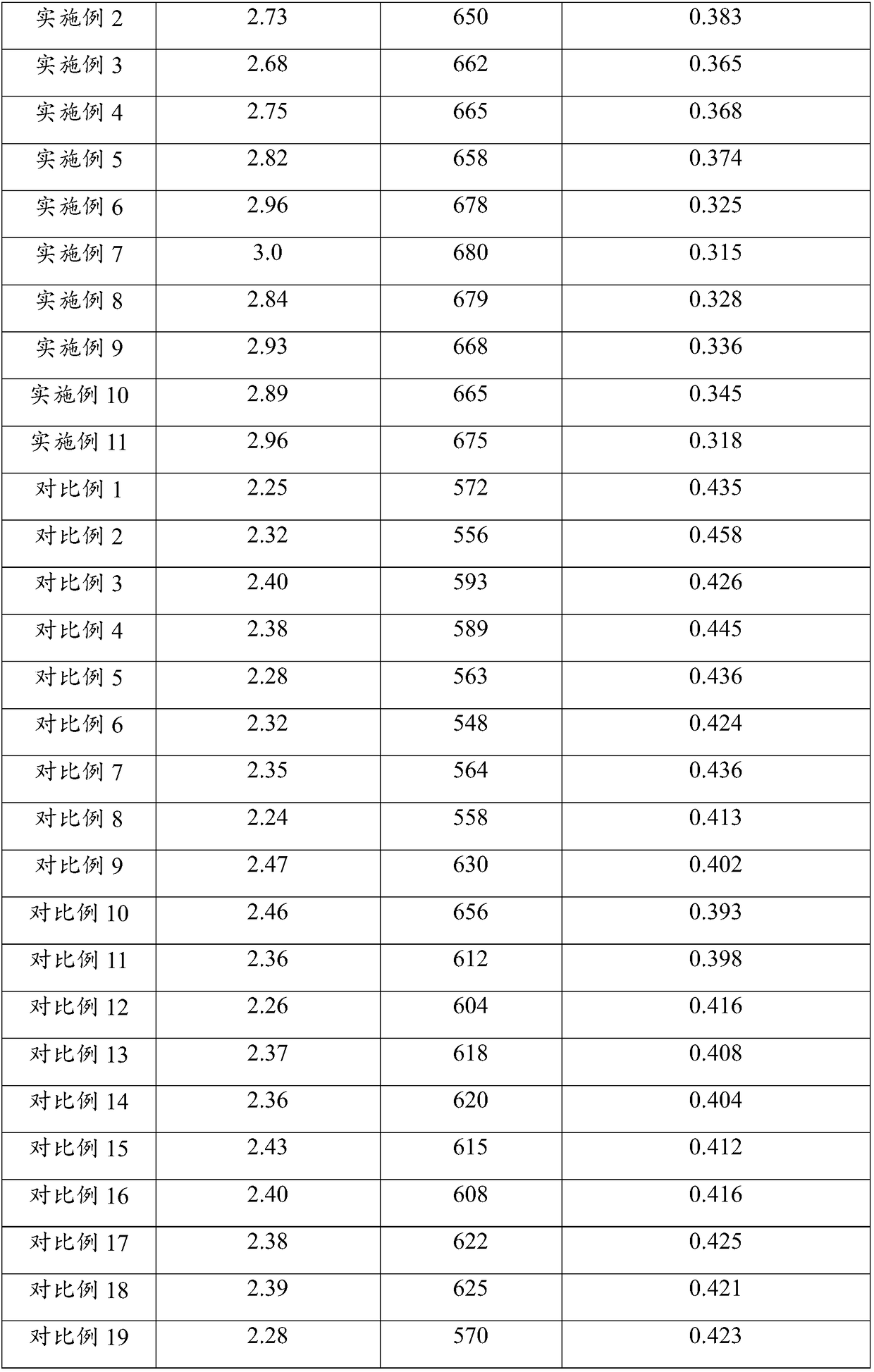

Examples

preparation example Construction

[0118] According to a second aspect of the present invention, there is provided a method for preparing an environment-friendly rubber prefabricated runway roll, comprising the following steps:

[0119] (a) heating, blending and extruding ethylene-propylene rubber, reclaimed rubber, linear low-density polyethylene and high-density polyethylene blends and paraffin oil in proportion to obtain an elastomer;

[0120] (b) The elastomer of step (a) is heated and blended with nano-rare earth oxide, vulcanizing agent, naphthenic oil, zinc oxide, filler, optional carbon nanotubes and optional carbon black in proportion, and extruded and embossing to obtain a sheet;

[0121] (c) Vulcanize, cool and curl the sheet to obtain an environmentally friendly rubber prefabricated runway roll.

[0122] Ethylene-propylene rubber, reclaimed rubber, linear low-density polyethylene and high-density polyethylene blends, paraffin oil, nano-rare earth oxides, vulcanizing agents, naphthenic oil, oxidatio...

Embodiment 1

[0149] An environment-friendly rubber prefabricated runway coil, made from the following raw materials in parts by weight: 30 parts of EPDM rubber, 64 parts of nitrile reclaimed rubber, 16 parts of chlorinated butyl reclaimed rubber, LLDPE and HDPE blend (LLDPE is linear low density polyethylene 7047) 50 parts, 1 part of nano cerium oxide, 10 parts of sulfur, 6 parts of paraffin oil, 15 parts of naphthenic oil, 1 part of zinc oxide and 200 parts of light calcium carbonate.

[0150] Its preparation method is as follows:

[0151] (1) Put EPDM rubber, nitrile reclaimed rubber, chlorinated butyl reclaimed rubber, LLDPE and HDPE blends and paraffin oil into the internal mixer according to the formula ratio for mixing. The temperature of the internal mixer is 120 ° C. The time is 10 minutes, and the banburying material is obtained, and the banburying material is put into an extruder, the extrusion temperature is 185° C., and the die head temperature is 160° C., to obtain an elastome...

Embodiment 2

[0156] An environment-friendly rubber prefabricated runway coil, made from the following raw materials in parts by weight: 60 parts of EPDM rubber, 30 parts of nitrile reclaimed rubber, 15 parts of chlorinated butyl reclaimed rubber, LLDPE and HDPE blend (LLDPE is linear low density polyethylene 9020) 20 parts, nano-lanthanum oxide 30 parts, sulfur 5 parts, paraffin oil 12 parts, naphthenic oil 10 parts, zinc oxide 5 parts and diatomaceous earth 50 parts.

[0157] Its preparation method is as follows:

[0158] (1) Put EPDM rubber, nitrile reclaimed rubber, chlorinated butyl reclaimed rubber, LLDPE and HDPE blends and paraffin oil into the internal mixer according to the formula ratio for mixing. The temperature of the internal mixer is 180 ° C. The time is 6 minutes, the banburying material is obtained, and the banburying material is put into an extruder, the extrusion temperature is 200° C., and the die head temperature is 180° C. to obtain an elastomer;

[0159] (2) Add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com