Manufacturing process of oil cylinder

A manufacturing process and oil cylinder technology, applied in the field of oil cylinder manufacturing process, can solve the problems of fast wear on the inner hole surface, reduced equipment reliability, limited service life, etc., and achieve uniform wear, improved flexibility, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

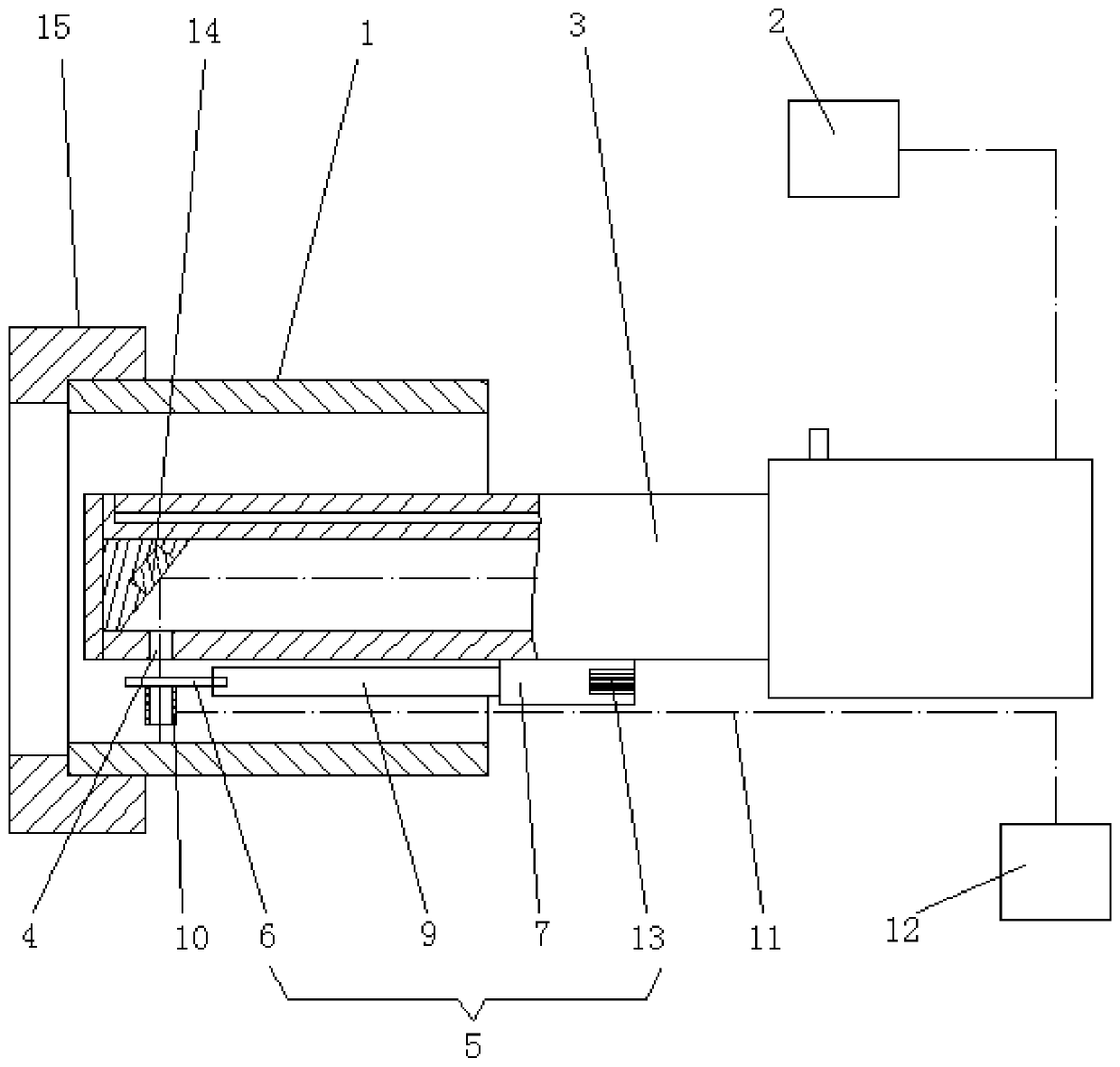

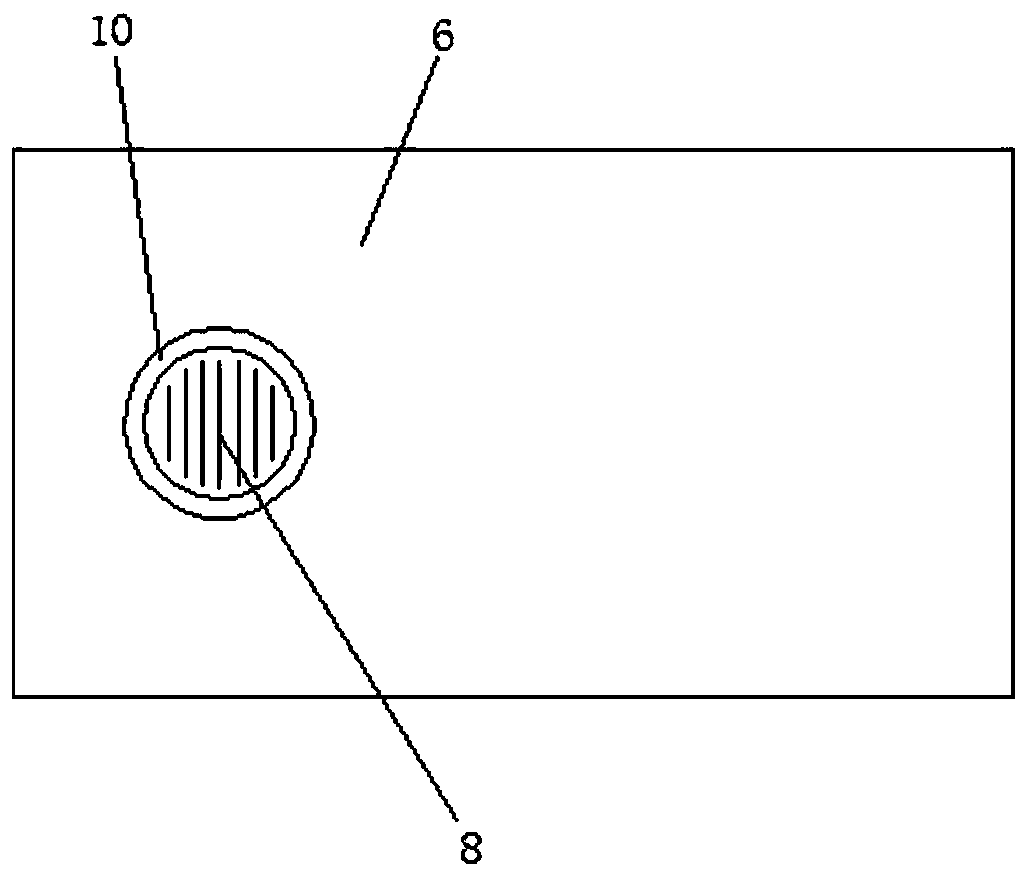

[0041] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

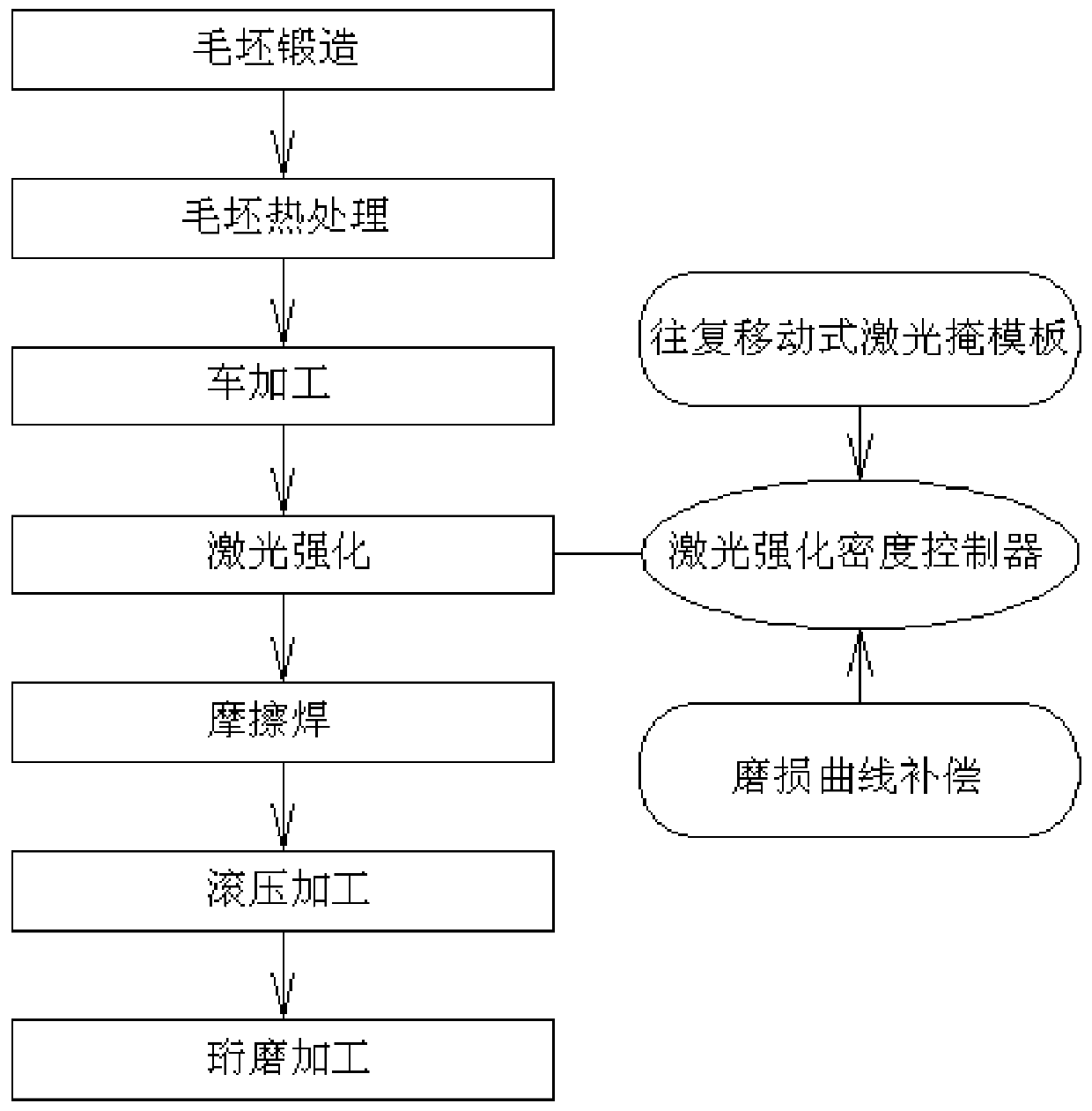

[0042] Such as Figures 1 to 3 Shown is the embodiment of the manufacturing process of a kind of oil cylinder of the present invention, comprises following process steps successively:

[0043] (1) rough forging;

[0044] (2) Blank heat treatment;

[0045] (3) Turning: Rough turning and finishing turning of the cylinder blank after forging and heat treatment;

[0046] (4) Laser strengthening: the oil cylinder is clamped on the rotary machine tool, and the laser strengthening treatment device is used to strengthen the surface of the inner hole of the oil cylinder;

[0047] (5) Honing: use honing equipment and a honing head to perform honing on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com