High-performance SiC/W metal ceramic composite nozzle and preparation method thereof

A metal-ceramic composite, high-performance technology, applied in the field of ceramic composite materials, can solve the problems of reduced temperature resistance of metal-ceramics, unsuitable food equipment, low product yield, etc., to reduce friction, easy control, green body strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

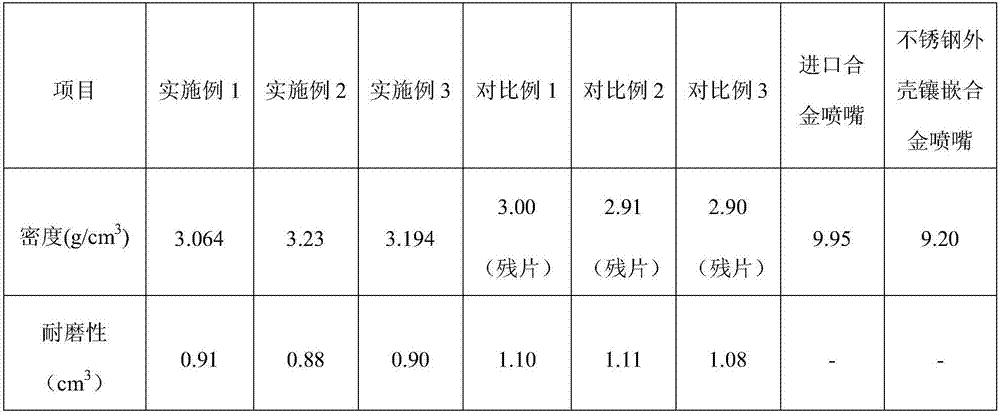

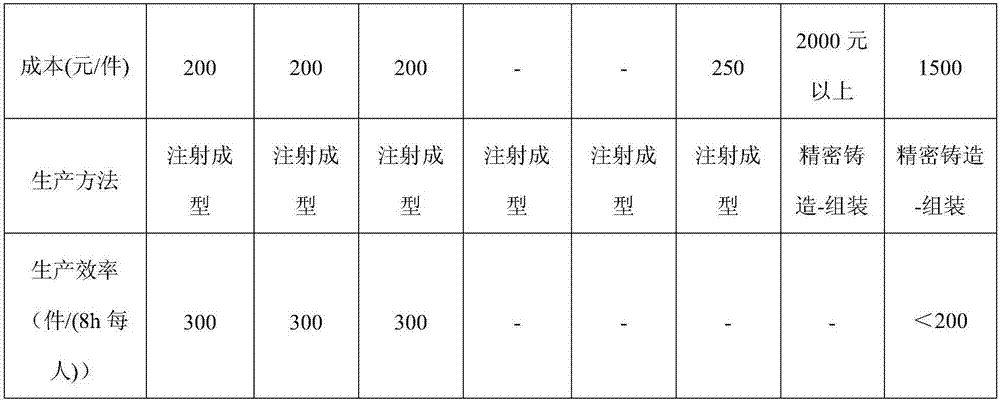

Examples

Embodiment 1

[0045] A high-performance SiC / W cermet composite nozzle, made by injection molding and sintering silicon carbide feed particles as raw material; the silicon carbide feed particle raw material is composed of the following components in mass percentage: %, boron carbide 3%, titanium diboride 3%, tungsten 1%, carbon black 2%, graphite 1%, paraffin 10%, high-density polyethylene 5%, ethylene vinyl acetate copolymer 2%, stearic acid 1 %.

[0046] Silicon carbide feed particles were prepared as follows:

[0047] Proportionally, take silicon carbide micropowder, boron carbide, titanium diboride, tungsten, carbon black, graphite and stearic acid and mix them evenly and add them to water. The amount of water added is silicon carbide, boron carbide, titanium diboride, tungsten , carbon black, graphite and stearic acid are 2 to 3 times the total amount of stearic acid, using silicon carbide balls as the grinding medium, and milling for 10 to 12 hours; after ball milling, the mixed slurr...

Embodiment 2

[0056] With the high-performance SiC / W cermet composite nozzle described in Example 1, the difference is that the silicon carbide feed particle raw material is composed of the following components by mass percentage: silicon carbide micropowder 70%, boron carbide 4 %, titanium diboride 1%, carbon black 3%, graphite 3%, tungsten 2%, paraffin 8%, high-density polyethylene 4%, ethylene vinyl acetate copolymer 3%, stearic acid 2%.

[0057] Silicon carbide feed particles were prepared as described in Example 1.

[0058] The preparation steps of high-performance SiC / W cermet composite nozzle are as follows:

[0059] (1) Injection molding: Add silicon carbide feed particles into the DRV4-55T injection molding machine, and inject molding under the conditions of injection pressure 110MPa and injection temperature 180°C to obtain a SiC / W cermet composite nozzle body;

[0060] (2) Drying: drying the obtained nozzle body at 40°C for 20 hours;

[0061] (3) Degreasing: Two-step degreasing...

Embodiment 3

[0066] The same as the high-performance SiC / W cermet composite nozzle described in Example 1, the difference is that the silicon carbide feed particle raw material is composed of the following components in mass percentage: silicon carbide fine powder 65%, boron carbide 5% %, titanium diboride 2%, tungsten 1.5%, carbon black 4%, graphite 3%, paraffin 9%, high-density polyethylene 5%, ethylene vinyl acetate copolymer 4%, stearic acid 1.5%.

[0067] Silicon carbide feed particles were prepared as described in Example 1.

[0068] The preparation steps of high-performance SiC / W cermet composite nozzle are as follows:

[0069] (1) Injection molding: Add silicon carbide feed particles into the DRV4-55T injection molding machine, and inject molding under the conditions of injection pressure 100MPa and injection temperature 170°C to obtain a SiC / W cermet composite nozzle body;

[0070] (2) Drying: drying the obtained nozzle body at 45°C for 18 hours;

[0071] (3) Degreasing: a two-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com