Diamond composite sheet and preparation method thereof

A diamond composite sheet and diamond technology are applied in the field of diamond composite sheet and its preparation to achieve the effects of enhanced impact toughness and thermal stability, improved radial temperature field distribution, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

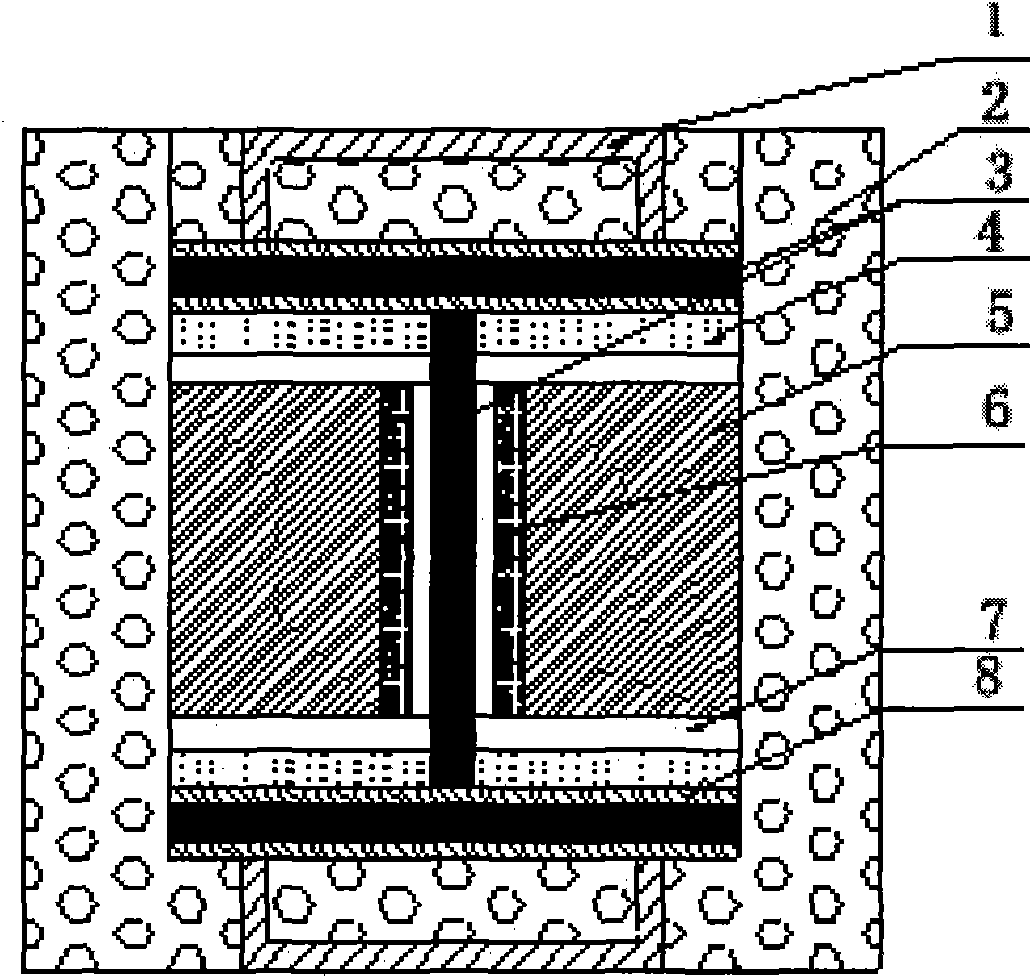

[0015] A diamond composite sheet is composed of a layer of 1mm-thick diamond on a hard alloy, and a layer of 0.1mm-thick polycrystalline diamond on the diamond by a vapor phase epitaxy growth method. The assembly method of the diamond composite sheet is as follows: pyrophyllite on the outer side and inner side is used as the pressure transmission medium, and ZrO2 is used on the outer side and inner circle 2 As insulation material, cylindrical NaCl cup as pressure and temperature equalization material, high temperature resistant metal Mo as shielding material, square graphite sheet as heat source to realize end surface heating.

[0016] The equipment for heating the end surface is a six-sided top press.

Embodiment 2

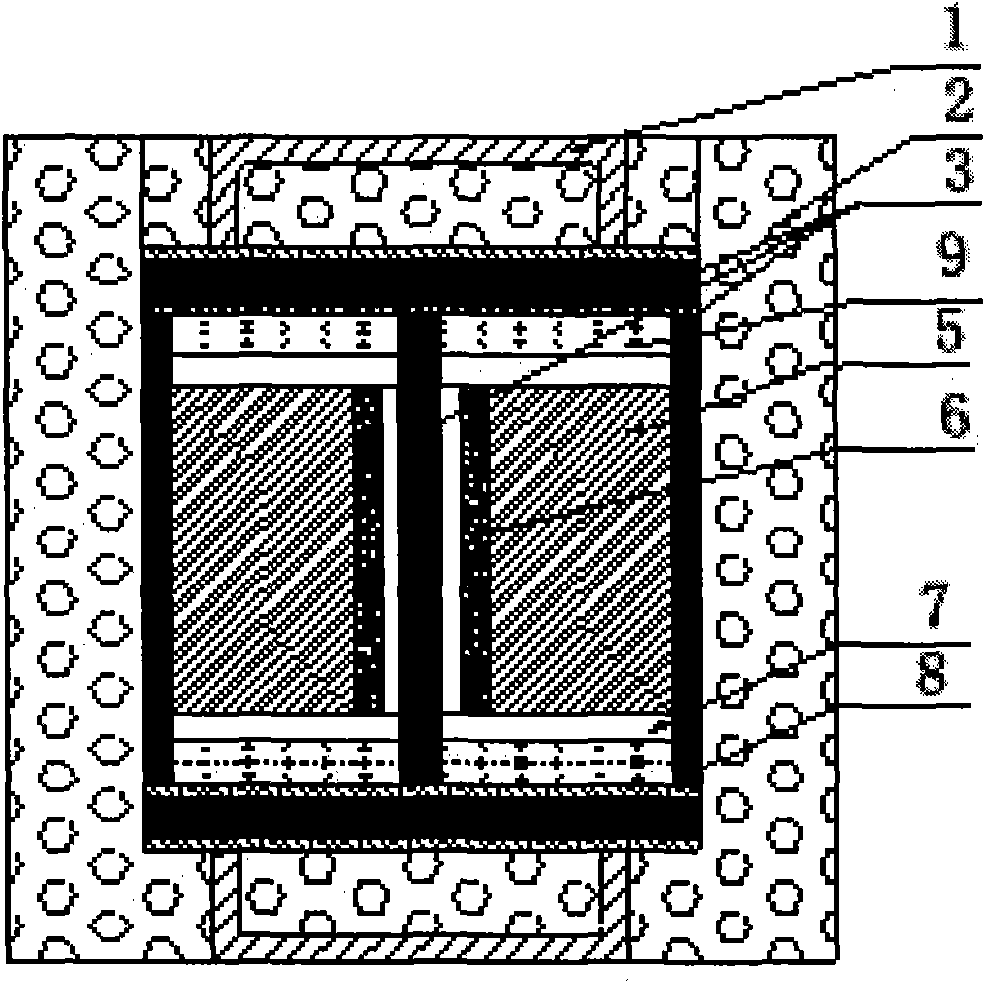

[0018] A diamond composite sheet is composed of a layer of 2mm-thick diamond on the cemented carbide, and a layer of 0.2mm-thick polycrystalline diamond on the diamond by vapor phase epitaxy growth method. The assembly method of the diamond composite sheet is as follows: use pyrophyllite on the outer side and inner side as the pressure transmission medium, MgO on the outer side and inner circle as the insulation material, the cylindrical NaCl cup as the pressure and temperature equalization material, and the high temperature resistant metal Ta as the shielding material. The square graphite sheet is used as a heat source to realize end surface heating.

[0019] The equipment for heating the end surface is a six-sided top press.

Embodiment 3

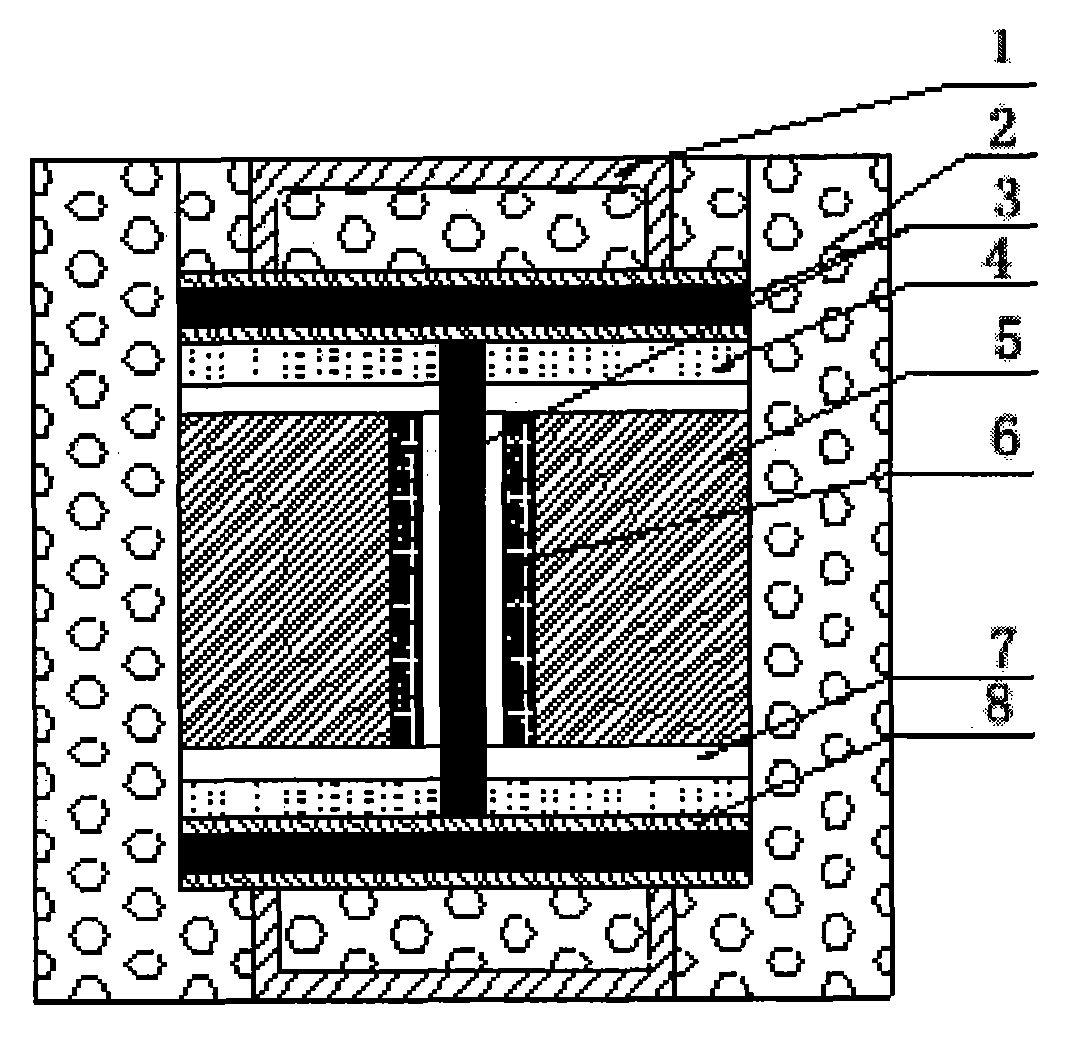

[0021] A diamond composite sheet is composed of a layer of 1.5mm thick diamond on the cemented carbide, and a layer of 0.15mm thick polycrystalline diamond on the diamond by vapor phase epitaxy growth method. The assembly method of the diamond composite sheet is as follows: use pyrophyllite on the outer side and inner side as the pressure transmission medium, MgO on the outer side and inner circle as the insulation material, the cylindrical NaCl cup as the pressure and temperature equalization material, and the high temperature resistant metal Ta as the shielding material. The square graphite sheet is used as a heat source to realize end surface heating.

[0022] The equipment for heating the end surface is a six-sided top press.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com