Preparation method of lubricating oil additive with antiwear and antifriction effect

A lubricating oil additive and functional technology, applied in the field of lubricating oil, can solve problems such as environmental pollution, large particle size, chemical corrosion, etc., and achieve the effects of protecting the environment, reducing particle wear, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

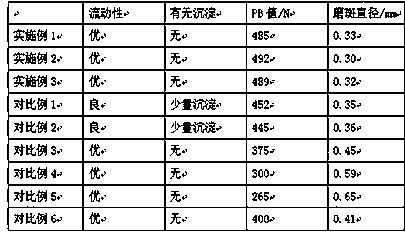

Examples

Embodiment 1

[0017] A preparation method of a lubricating oil additive with anti-wear and anti-friction effects, the specific preparation method is as follows:

[0018] 1) Take 20 parts of 4,4-diphenylmethane diisocyanate in the reactor, melt at 50°C, then add 15 parts of hydroxyethyl methacrylate, and stir the reaction at 60°C at a speed of 50r / min 30 minutes, then add 5 parts of hydroxyl silicone oil and 30 parts of macromolecular diols after vacuum dehydration, catalyze with 0.2 parts of triethylamine, continue to stir and react for 50 minutes, then take 10 parts of di-n-butylammonium, add to the same equivalent 4,4-diphenylmethane diisocyanate, mixed and stirred at 100r / min for 10min, then added to the above reaction system, stirred and reacted at 50°C at a speed of 60r / min for 80min, to obtain a prepolymer;

[0019] 2) Add 0.6 parts of aromatic diamine to 3 parts of 1,4-butanediol, stir to dissolve and then add to the prepared prepolymer, stir at a speed of 100r / min for 30min, and the...

Embodiment 2

[0029] A preparation method of a lubricating oil additive with anti-wear and anti-friction effects, the specific preparation method is as follows:

[0030] 1) Put 25 parts of 4,4-diphenylmethane diisocyanate into the reactor, melt at 55°C, then add 20 parts of hydroxyethyl methacrylate, and stir the reaction at 65°C at a speed of 70r / min 25 minutes, then add 7 parts of hydroxyl silicone oil and 40 parts of macromolecular diols after vacuum dehydration, catalyze with 0.4 parts of triethylamine, continue to stir and react for 60 minutes, then take 13 parts of di-n-butylammonium, add to the same equivalent 4,4-diphenylmethane diisocyanate, mixed and stirred at 120r / min for 7min, then added to the above reaction system, stirred and reacted at 55°C at a speed of 80r / min for 70min, to obtain a prepolymer;

[0031] 2) Add 0.7 parts of aromatic diamine to 4 parts of 1,4-butanediol, stir to dissolve and add to the prepared prepolymer, stir at a speed of 150r / min for 25min, and then add...

Embodiment 3

[0041] A preparation method of a lubricating oil additive with anti-wear and anti-friction effects, the specific preparation method is as follows:

[0042] 1) Take 30 parts of 4,4-diphenylmethane diisocyanate in the reactor, melt at 60°C, then add 25 parts of hydroxyethyl methacrylate, and stir the reaction at 70°C at a speed of 80r / min 20 minutes, then add 8 parts of hydroxyl silicone oil and 50 parts of macromolecular diols after vacuum dehydration, catalyze with 0.5 parts of triethylamine, continue to stir and react for 70 minutes, then take 15 parts of di-n-butylammonium, add to the same equivalent 4,4-diphenylmethane diisocyanate, mixed and stirred at 150r / min for 5min, then added to the above reaction system, stirred and reacted at 60°C at a speed of 100r / min for 60min, to obtain a prepolymer;

[0043] 2) Add 0.8 parts of aromatic diamine to 5 parts of 1,4-butanediol, stir to dissolve and then add to the prepared prepolymer, stir for 20 minutes at a speed of 200r / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com