Low abrasion drum-type brake facing and preparation method thereof

A brake lining, low-wear technology, used in friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of unstable friction coefficient and fast wear, improve quality stability, reduce adhesive wear, wear and tear the effect of reducing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the low-wear drum brake lining, comprising the following steps:

[0032] (1) Raw material mixing: steel fiber, precipitated barium sulfate, phenolic resin and mineral fiber are mixed, then adding raw material components other than glass fiber, and finally adding glass fiber to obtain a raw material mixture;

[0033] (2) Hot pressing: Pour the raw material mixture into the mold for hot pressing;

[0034] (3) Heat treatment: heat treatment is performed on the hot-pressed products.

[0035] In one embodiment of the present invention, in step (1), steel fiber, precipitated barium sulfate, phenolic resin and mineral fiber are mixed 4~8min, then add the raw material component except glass fiber, mix 3~6min, because The glass fiber is brittle and needs to be added last, and the raw material mixture is obtained after mixing for 1-2 minutes.

[0036] In one embodiment of the present invention, in step (2), the time of...

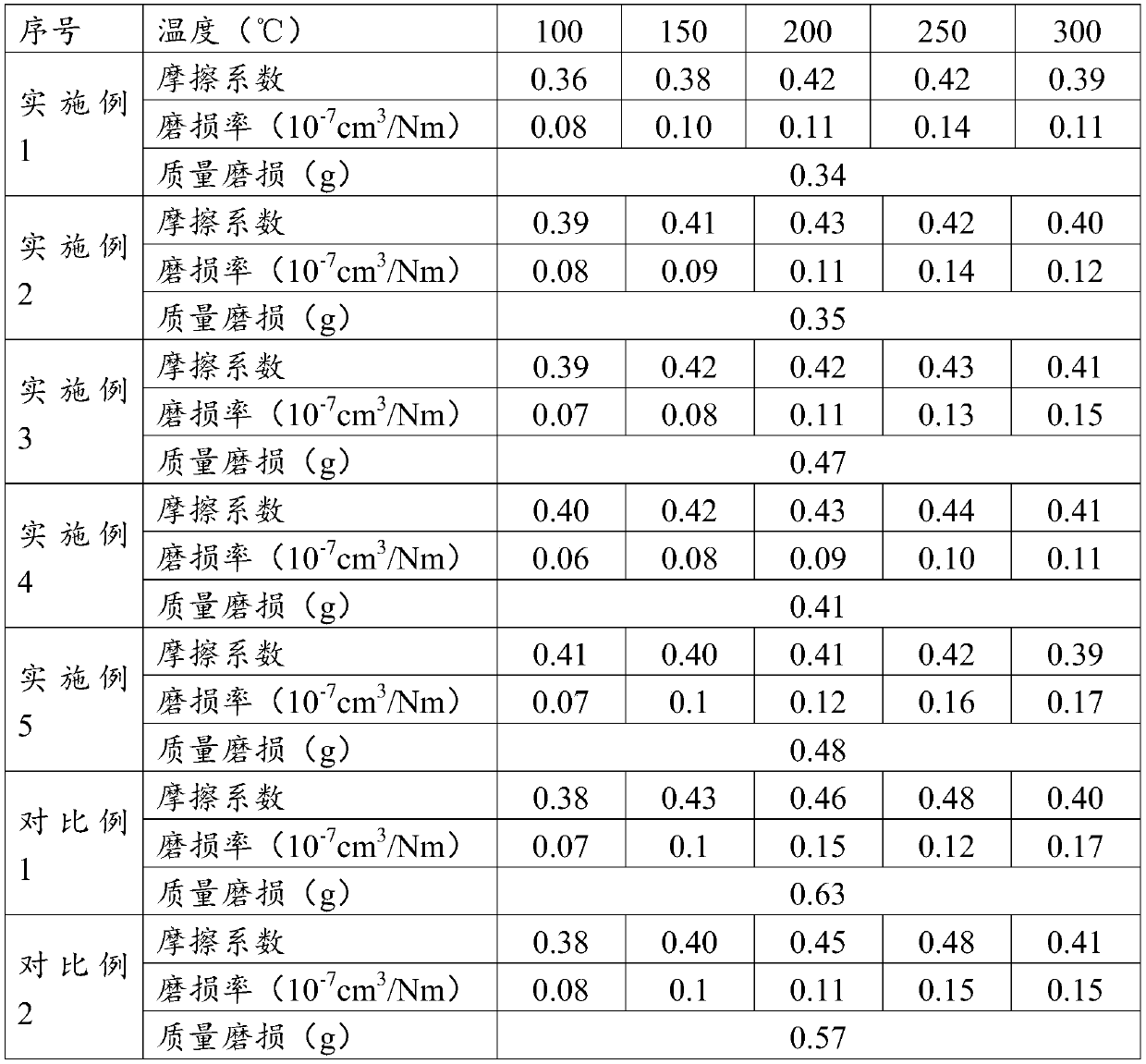

Embodiment 1

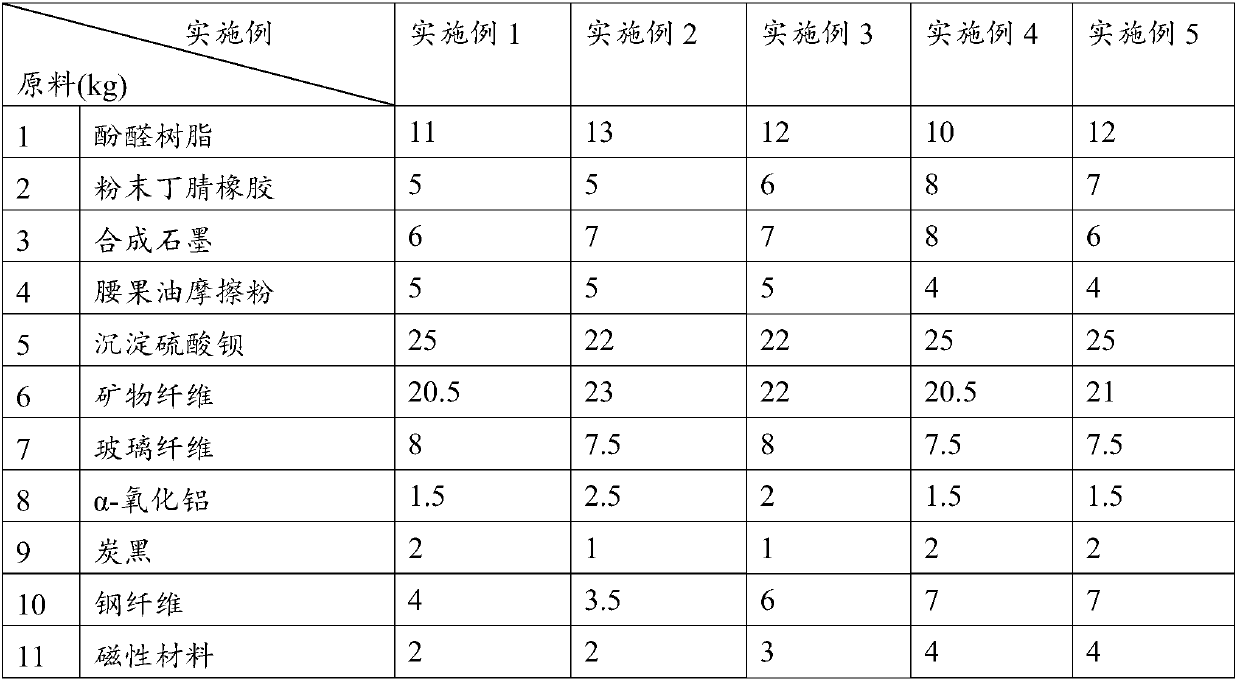

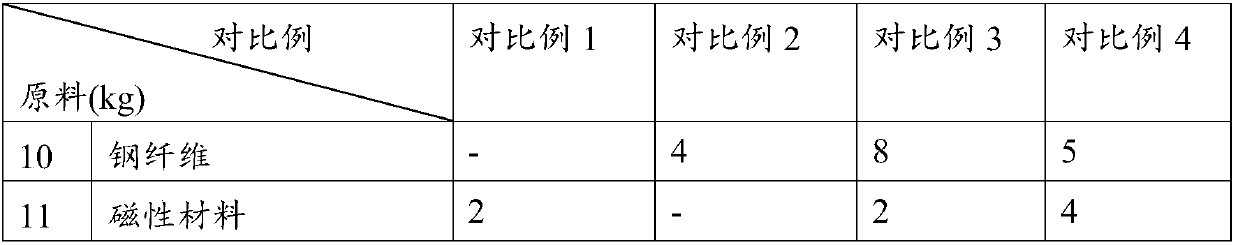

[0044] A drum brake lining, the materials and dosages of Examples 1 to 5 are shown in Table 1.

[0045] The material consumption table of table 1 embodiment 1~5

[0046]

[0047] The preparation method of this liner is:

[0048] (1) Raw material mixing: first, add steel fiber, precipitated barium sulfate, phenolic resin, and mineral fiber into the plow mixer and mix for 7 minutes for premixing; secondly, add the remaining formula materials (except glass fiber) Add it to the plow-rake mixer, mix at high speed for 4 minutes, and finally add glass fiber, and only turn on the plow and rake for 2 minutes to mix the materials evenly;

[0049] (2) Packing bag: weigh according to the feeding amount on the process card, put it into the packing bag, and then seal it;

[0050](3) Compression: Using a one-step molding method, put the packaged plastic pressing material into the mold groove of the hot press machine. The control temperature of hot pressing is 140-160°C, and the pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com