Powder metallurgy self-lubricating bearing and preparation method thereof

A technology of self-lubricating bearings and powder metallurgy, which is applied to bearings, bearing components, shafts and bearings, etc., can solve the problems of poor control of graphite addition, affecting bearing crushing strength, and low service life of steel bearings, so as to improve self-lubricating bearings. Lubrication effect, improvement of friction and wear performance, and effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

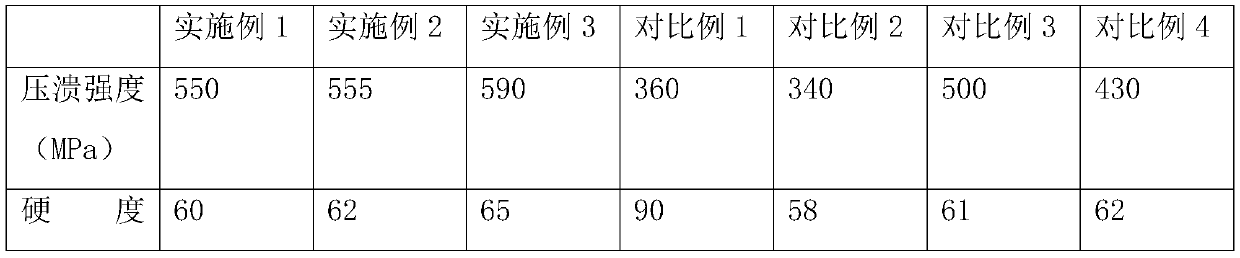

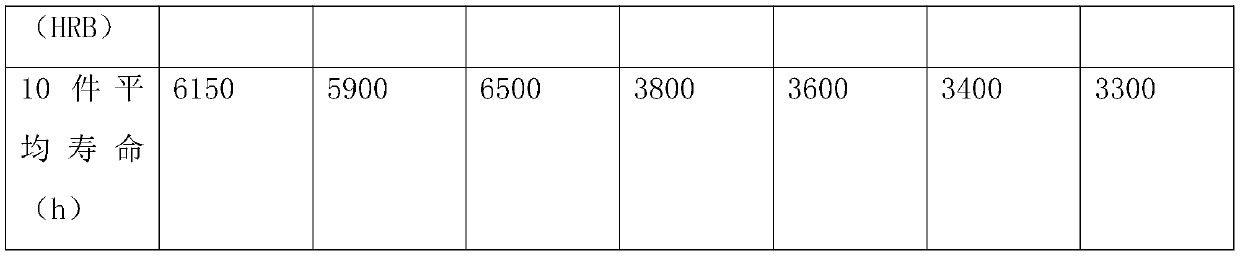

Embodiment 1

[0028] A method for preparing a powder metallurgy self-lubricating bearing, comprising the following steps:

[0029] (1) raw materials are mixed, and described raw material is made up of the component of following percentage by weight: carbon 2%, copper 2%, molybdenum disulfide 1.5%, iron surplus;

[0030] (2) Compression molding, the green body density after molding is 6.82g / cm 3 ;

[0031] (3) Sintering, the sintering temperature is 1120°C, the temperature is kept for 30 minutes, and the whole process is protected by nitrogen gas.

[0032] (4) Oil immersion treatment, immersion in 32# engine oil, oil temperature 75°C, vacuum pressure value 0.1mpa, time 30min; after oil immersion, the oil content is 13.5%. After oil immersion, the oil content of the material is tested by volume percentage computational.

Embodiment 2

[0034] A method for preparing a powder metallurgy self-lubricating bearing, comprising the following steps:

[0035] (1) mixing the raw materials, the raw materials are made up of the following components in weight percentage: 2.5% carbon, 1% copper, 0.5% molybdenum disulfide, and iron balance;

[0036] (2) Compression molding, the green body density after molding is 6.83g / cm 3 ;

[0037] (3) Sintering, the sintering temperature is 1120°C, the temperature is kept for 40 minutes, and the whole process is protected by nitrogen gas.

[0038] (4) Oil immersion treatment, immerse in 32# engine oil, the oil temperature is 85°C, the vacuum pressure value is 0.1mpa, and the time is 20min; the oil content after oil immersion is 13.5%. After oil immersion, the oil content of the material is calculated by volume percentage.

Embodiment 3

[0040] A method for preparing a powder metallurgy self-lubricating bearing, comprising the following steps:

[0041] (1) raw materials are mixed, and described raw material is made up of the component of following percentage by weight: carbon 2.3%, copper 1.5%, molybdenum disulfide 1%, iron balance;

[0042] (2) Compression molding, the green body density after molding is 6.82g / cm 3 ;

[0043] (3) Sintering, the sintering temperature is 1120°C, the temperature is kept for 35 minutes, and the whole process is protected by nitrogen gas.

[0044] (4) Oil immersion treatment, immersion in 32# engine oil, oil temperature 80°C, vacuum pressure value 0.1mpa, time 25min; oil content after oil immersion is 14%, after oil immersion, the oil content of the material is tested by volume percentage computational.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com