A reinforced method of guiding surfaces in guiding protection equipment of long thin embossing dies

A protective device, slender technology, applied in the direction of forming tools, furnace types, liquid chemical plating, etc., can solve the problems of insufficient strength, hardness, wear resistance, etc., achieve high price, save mold material costs, and guide the length of protection increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

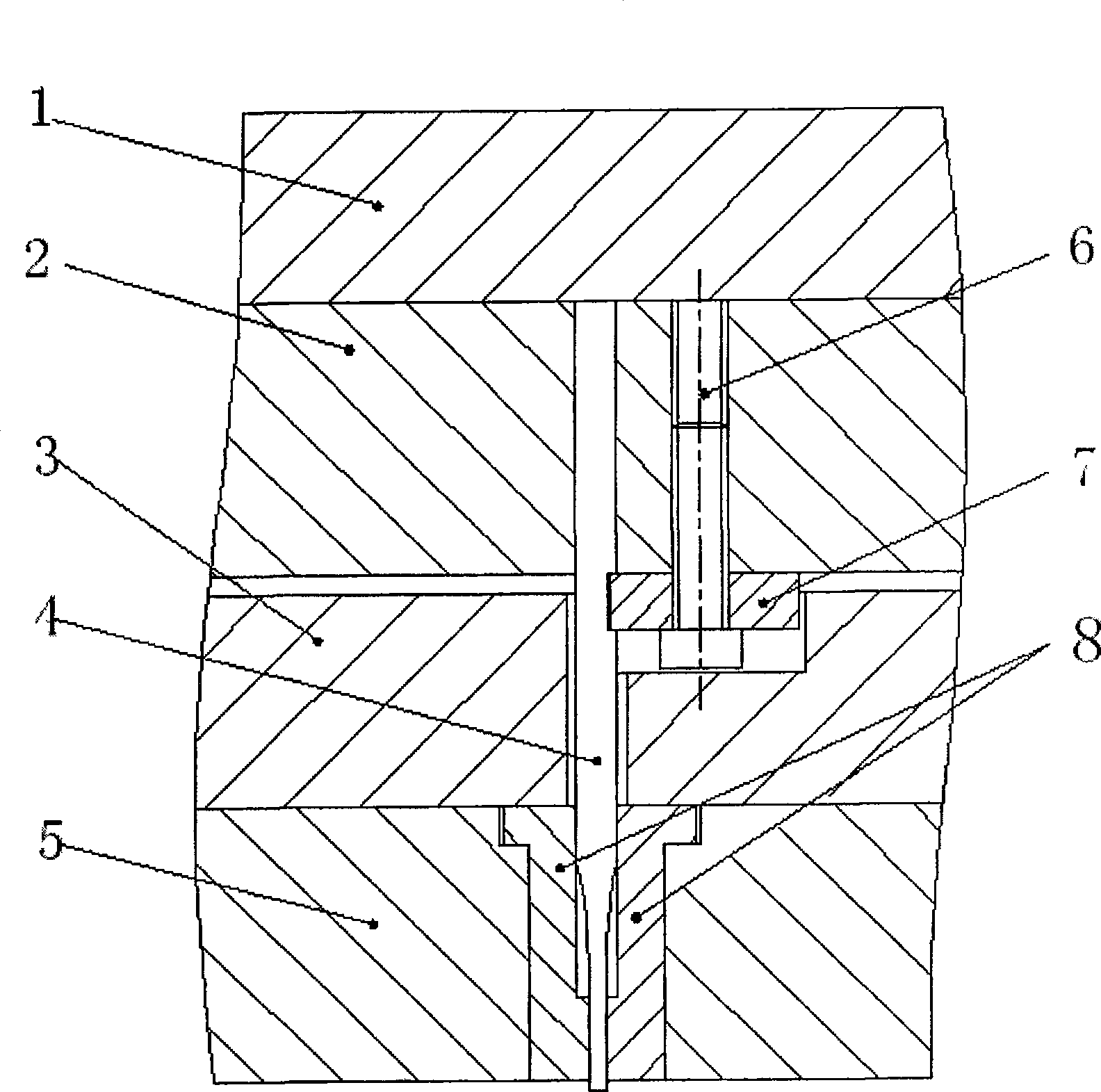

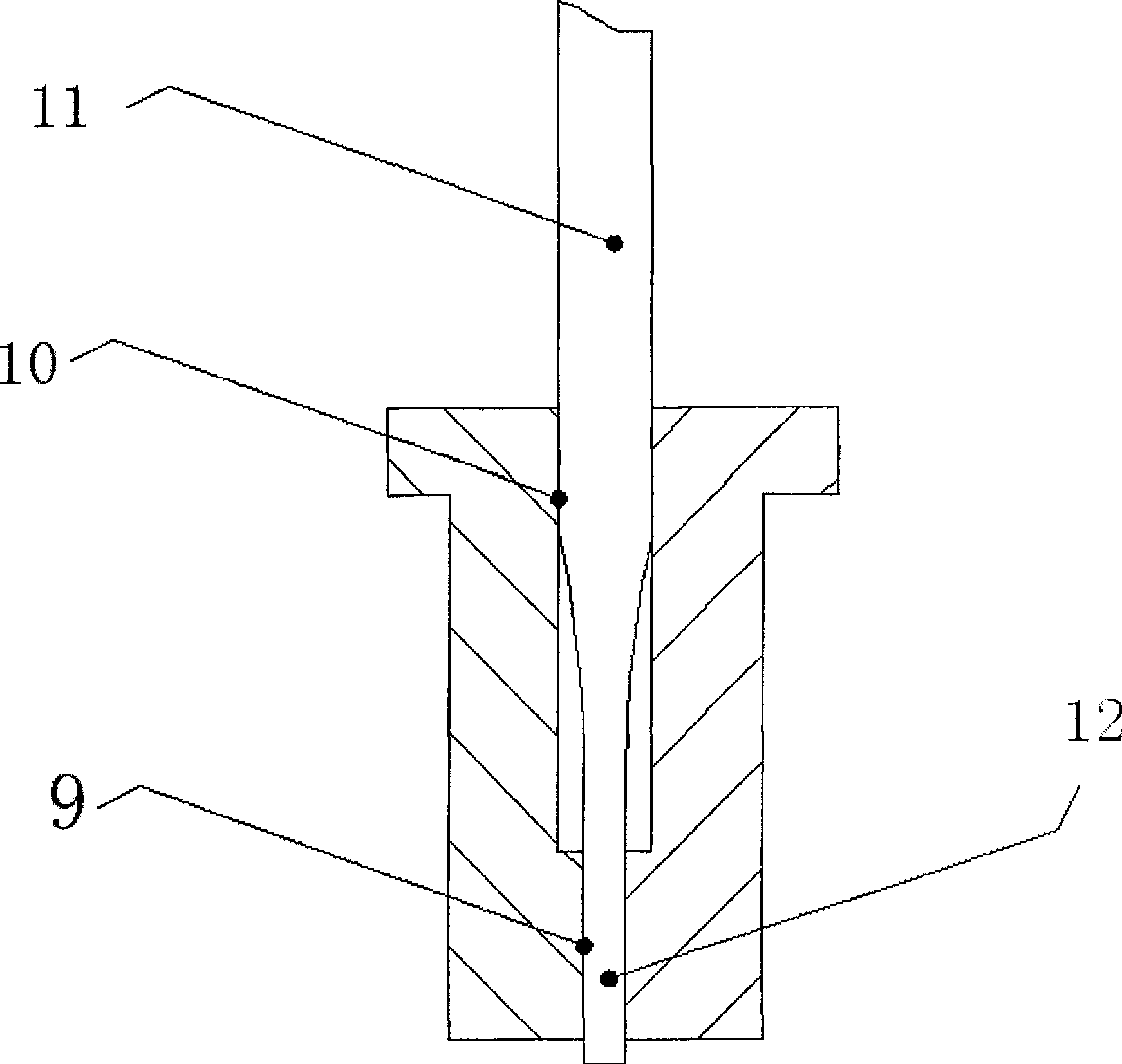

[0024] Such as figure 1 Shown is the structure of the slender punch double-guided protective cover, the punch fixed plate 2, the discharge backing plate 3, the slender punch 4, the discharge plate 5 and the double-guided protective cover 8 are located on the upper backing plate 1 One side; the elongated punch 4 is positioned in the punch fixing plate 2, and is clamped by the splint 7 and the screw A6; the upper backing plate 1 and the punch fixing plate 2 are fixedly connected by the screw B; Thus upper backing plate 1, punch fixed plate 2, elongated punch 4, punch splint 7 and screw A6 constitute a fixed assembly 1. The double-guided protective sleeve 8 is embedded in the unloading plate 5, and the unloading plate 5 and the unloading backing plate 3 are fixedly connected by screws C. The unloading backing plate 3, the unloading plate 5 and the double-guiding protective sleeve 8 Or fixed connection constitutes another component II. The components I and II are flexibly connec...

Embodiment 2

[0027] exist figure 1 Among them, the material of the slender punch 4 is cemented carbide CD650, the material of the double-guided protective sleeve 8 is common tool steel, and the nickel-phosphorus nano-silicon carbide composite coating is applied on the surface, and the phosphorus content in the coating is 5-9%. Nickel is 91-95%, there is a small amount of nano-silicon carbide, and the hardness of the coating is 900-1100Hv.

[0028] The operation process of applying coating to the guide profile of the device described in Example 1 is to carry out ultrasonic degreasing, rust removal, chemical composite plating and heat treatment on the double guide protective sleeve. The method for strengthening the guide profile of the guide protection device of the precision slender punch includes the following process steps in sequence:

[0029] (1) First, the double-guided protective sleeve is treated with ultrasonic degreasing, the temperature of the degreasing is set at 80° C., and the...

Embodiment 1

[0036] The strengthening process of the guide profile of the guide protection device of the precision slender punch described in Example 1:

[0037] (1) First, the double-guided protective sleeve is treated with ultrasonic degreasing, the temperature of the degreasing is set at 60° C., and the time is 15 minutes. The degreasing formula is: sodium hydroxide (NaOH, 97% (weight percentage)): 60 -80g / L, sodium phosphate (Na 3 PO 4 12H 2 O, 97%): 25g / L, sodium carbonate (Na 2 CO 3 , 97%): 25g / L;

[0038] (2) Ultrasonic derusting treatment is then performed on the double-guided protective sleeve. The temperature of derusting is set to room temperature, and the time is 1 minute. The derusting formula is: hydrochloric acid (HCl, 37%): 25ml / L, sulfuric acid (H 2 SO 4 , 98%): 5ml / L;

[0039] (3) Carry out chemical composite plating to the double-guided protective sleeve again, the temperature of chemical composite plating is set at 90 ℃, the time is 90 minutes, and the formula of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com