Heat-resisting dust collecting bag

A technology of high temperature resistance and cloth bag, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. It can solve the problems of affecting normal use, bending and wrinkling of filter bags, and poor high temperature resistance, so as to reduce adhesive wear. , Improve the bonding performance, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

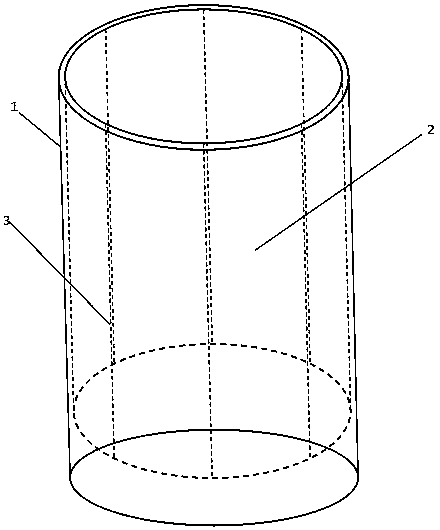

[0019] like figure 1 As shown, it is a high-temperature-resistant dust-removing cloth bag according to the present invention, which includes a cloth bag 1 and a bag cage 2 arranged in the cloth bag 1. The bag cage 2 is a hollow cylinder structure with support rods 3 arranged on it; The bag mouth hoop of 1 is arranged on the upper part of bag cage 2, and the inner diameter of the bag of described cloth bag 1 is larger than the diameter of the cross section of described bag cage 2.

[0020] As a further optimization of this embodiment, the cloth bag 1 is made of high temperature resistant materials, specifically the following raw materials in parts by weight:

[0021] 40 parts of polytetrafluoroethylene resin emulsion, 15 parts of glass fiber, 10 parts of carbon fiber, 0.5 parts of samarium oxide, 6 parts of nano-titanium dioxide, 6 parts of potassium titanate whiskers, parts of aluminum disulfide, parts of nitric acid, 2 parts of silicon fluoride, 5 parts of γ-methacryloxyprop...

Embodiment 2

[0027] like figure 1 As shown, it is a high-temperature-resistant dust-removing cloth bag according to the present invention, which includes a cloth bag 1 and a bag cage 2 arranged in the cloth bag 1. The bag cage 2 is a hollow cylinder structure with support rods 3 arranged on it; The bag mouth hoop of 1 is arranged on the upper part of bag cage 2, and the inner diameter of the bag of described cloth bag 1 is larger than the diameter of the cross section of described bag cage 2.

[0028] As a further optimization of this embodiment, the cloth bag 1 is made of high temperature resistant materials, specifically the following raw materials in parts by weight:

[0029] 45 parts of polytetrafluoroethylene resin emulsion, 18 parts of glass fiber, 13 parts of carbon fiber, 0.6 parts of samarium oxide, 7 parts of nano-titanium dioxide, 7 parts of potassium titanate whiskers, 3 parts of aluminum disulfide, 2 parts of nitric acid, 3 parts of silicon fluoride Parts, 6 parts of γ-methac...

Embodiment 3

[0035] like figure 1 As shown, it is a high-temperature-resistant dust-removing cloth bag according to the present invention, which includes a cloth bag 1 and a bag cage 2 arranged in the cloth bag 1. The bag cage 2 is a hollow cylinder structure with support rods 3 arranged on it; The bag mouth hoop of 1 is arranged on the upper part of bag cage 2, and the inner diameter of the bag of described cloth bag 1 is larger than the diameter of the cross section of described bag cage 2.

[0036] As a further optimization of this embodiment, the cloth bag 1 is made of high temperature resistant materials, specifically the following raw materials in parts by weight:

[0037] 50 parts of polytetrafluoroethylene resin emulsion, 20 parts of glass fiber, 15 parts of carbon fiber, 0.7 parts of samarium oxide, 8 parts of nano-titanium dioxide, 8 parts of potassium titanate whiskers, 4 parts of aluminum disulfide, 3 parts of nitric acid, and 4 parts of silicon fluoride Parts, 7 parts of γ-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com