Impeller supercharging solid self-lubricating grinding wheel matrix structure

A solid self-lubricating, grinding wheel technology, used in bonded grinding wheels, abrasives, metal processing equipment, etc., can solve the problem of not meeting the actual needs of grinding cooling, contrary to green environmental protection, and hindering the effective entry of grinding fluid into the grinding arc. It can reduce the friction coefficient, protect the environment, and inhibit surface burns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, introduce the content of the present invention in detail.

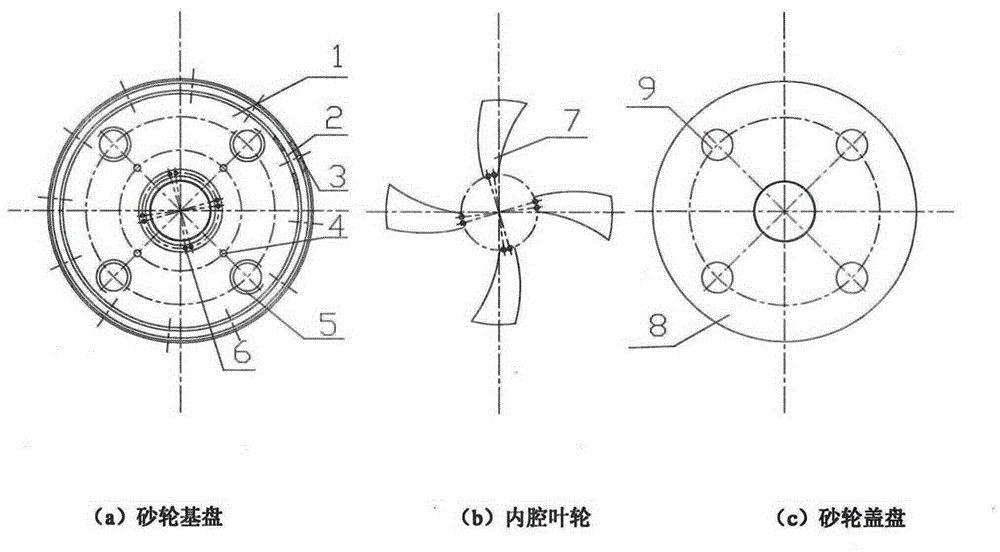

[0014] Such as figure 1 As shown in FIG. 2 , the grinding wheel structure is mainly composed of a grinding wheel base plate 1 , an impeller 7 and a cover plate 8 . When assembling, first install the impeller on the impeller base 6 of the base plate, adjust the opening of the one-way air outlet valve 2, and fill the annular cavity of the base plate with solid lubricant, and pass the cover plate 8 through the hexagon socket bolt It is fixed on the base plate of the grinding wheel, and a layer of sealant is applied on the contact point. When the grinding wheel rotates at high speed, it drives the impeller 7 inside the base plate of the grinding wheel to rotate at high speed at the same time. The airflow entering from the air inlet 4 passes through the single The air outlet valve 2 enters the inner cavity of the ring groove on the grinding wheel base plate, and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com