Method for calculating sliding shoe-chuck wear life of plunger pump

A calculation method and wear life technology, applied in calculation, special data processing applications, instruments, etc., can solve the problems of lack of sliding shoes and chucks, increased oil return, less research on the wear of sliding shoes and chucks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below with reference to the drawings and embodiments.

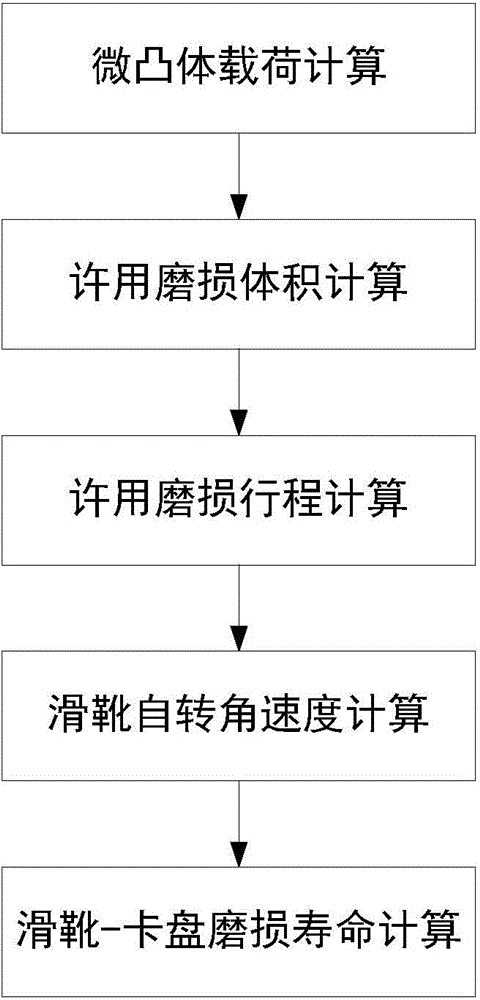

[0054] The invention is a method for calculating the wear life of the plunger pump slipper-chuck, see figure 2 As shown, the specific steps of the method are as follows:

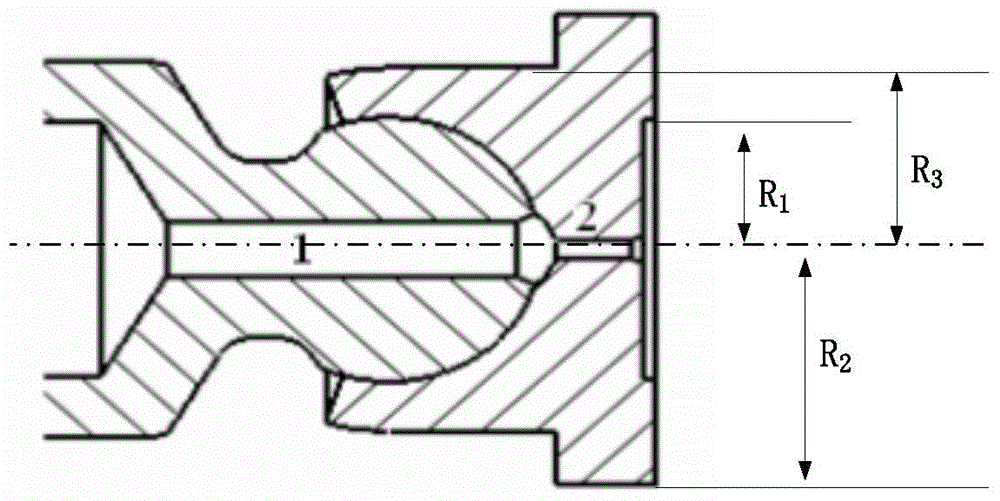

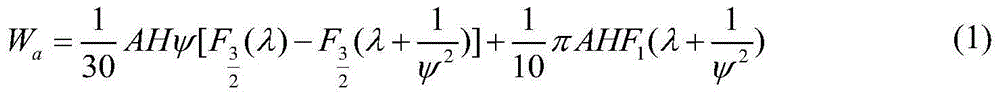

[0055] Step 1: Calculation of the asperity load. Since the annular surface of the sliding shoe and the chuck are in a clearance fit, there is an oil film between the chuck and the annular surface of the sliding shoe during the working process of the hydraulic pump, and there is no direct contact, so the normal pressure of the chuck to the sliding shoe W a Is the asperity load. If A represents the nominal contact area between the upper surface of the shoe and the chuck, and H represents the hardness of the upper surface of the shoe, the calculation formula for the asperity load is shown in formula (1):

[0056] W a = 1 30 AHψ [ F 3 2 ( λ ) - F 3 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com