Multi-field coupled spatial conductive slip ring wear modeling and life prediction method

A conductive slip ring, life prediction technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as increased wear, slip ring failure, slip ring conductivity, etc., to avoid high costs, good The effect of referential meaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings.

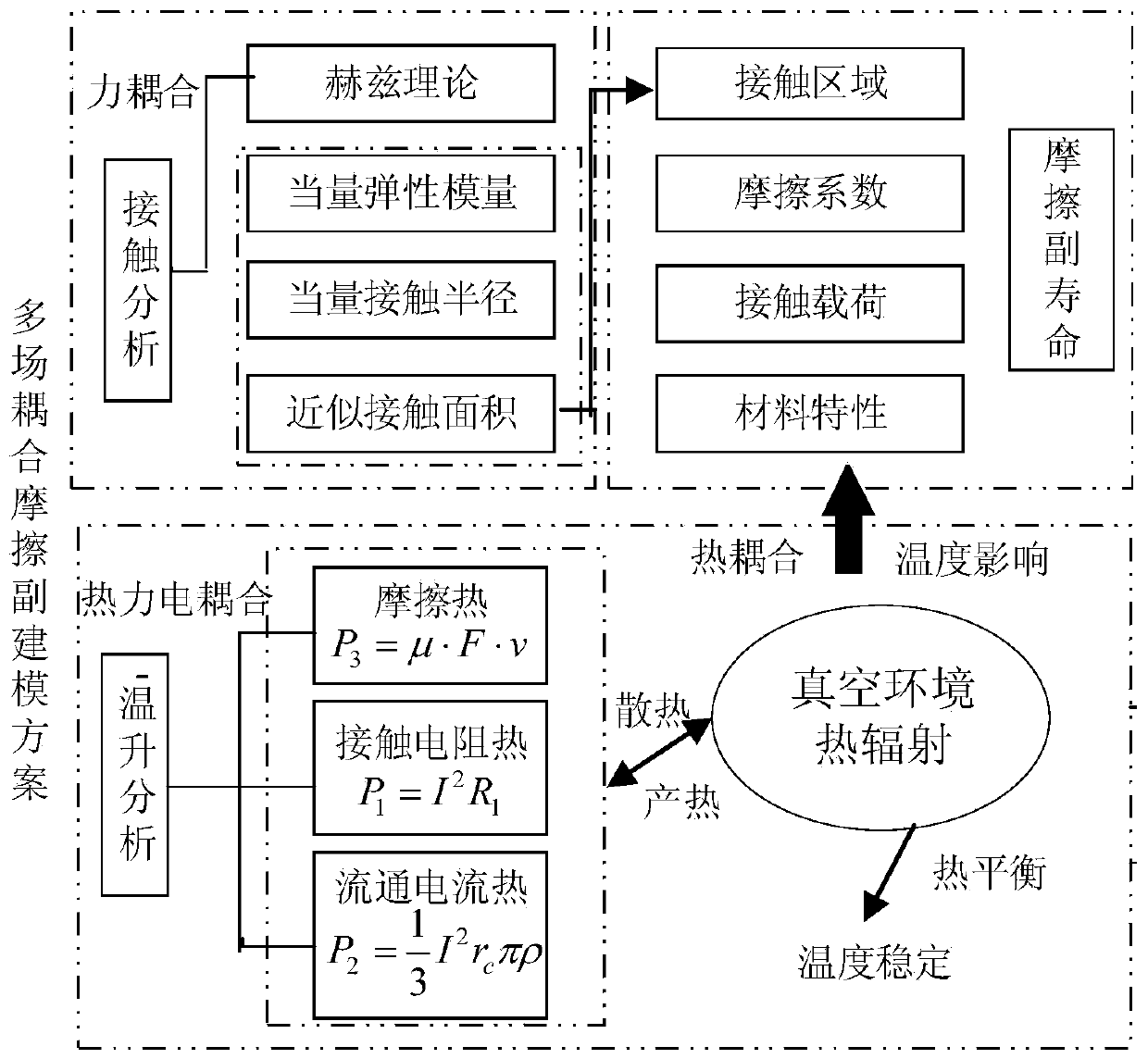

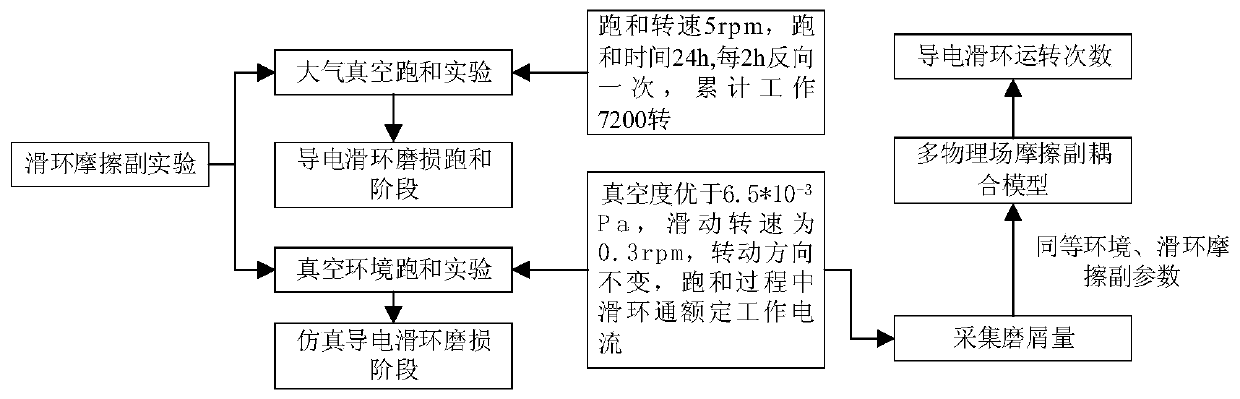

[0056] Such as figure 1 As shown, the space conductive slip ring friction and wear analysis and life prediction method provided by the present invention comprises the following steps:

[0057] Step 1. Use Hertz theory to calculate the contact area of the slip ring friction pair;

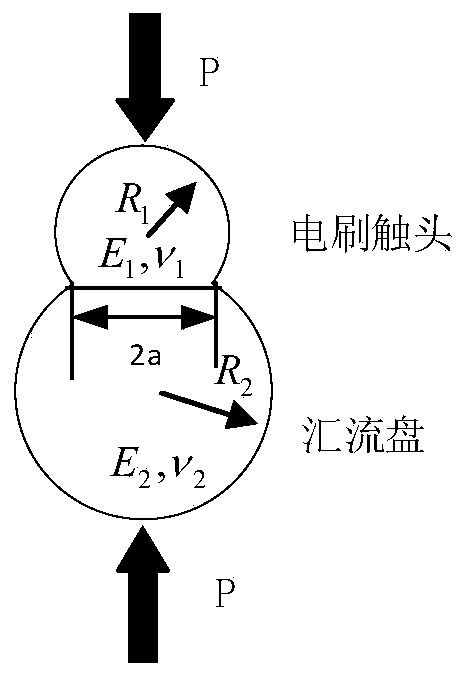

[0058] The contact of the friction pair of the conductive slip ring belongs to point-to-point contact, and the contact of the conductive slip ring is approximately ellipsoidal, and the contact between the contact and the bus plate produces elastic deformation. Secondary wear severity, the present invention calculates the elastic deformation contact area between the two through the Hertz theory, and the friction pair contact model can be known by the Hertz theory as figure 2 As shown, when the contact is in contact with the bus plate, the contact surface is approximately regarded as a cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com