Patents

Literature

31results about How to "Reduce non-conformities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

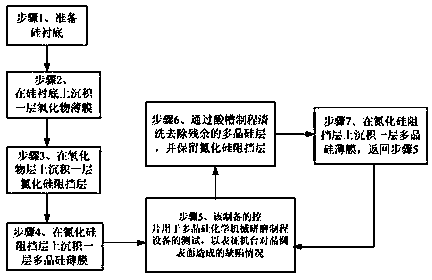

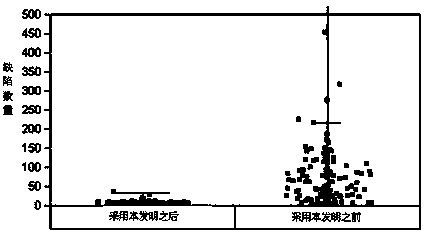

Making method for defect detection wafer used in polysilicon chemical mechanical grinding process

InactiveCN103887147AWill not harmNo void defectsSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingSilicon oxidePolycrystalline silicon

The invention relates to a making method for a defect detection wafer used in a polysilicon chemical mechanical grinding process. A thin silicon oxide film is deposited on a silicon substrate, a silicon nitride barrier layer is deposited on the silicon oxide layer, a polysilicon film is deposited on the silicon nitride barrier layer, and the silicon nitride layer is retained during cycle use. According to the making method, the silicon nitride barrier layer is additionally arranged, so a problem of influence on a machine test result because of COP defects caused by damage to the silicon substrate in a cycle use process of the wafer can be effectively settled, and thereby errors in a detection process are reduced, and the real detection data which represents machine performance can be acquired.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

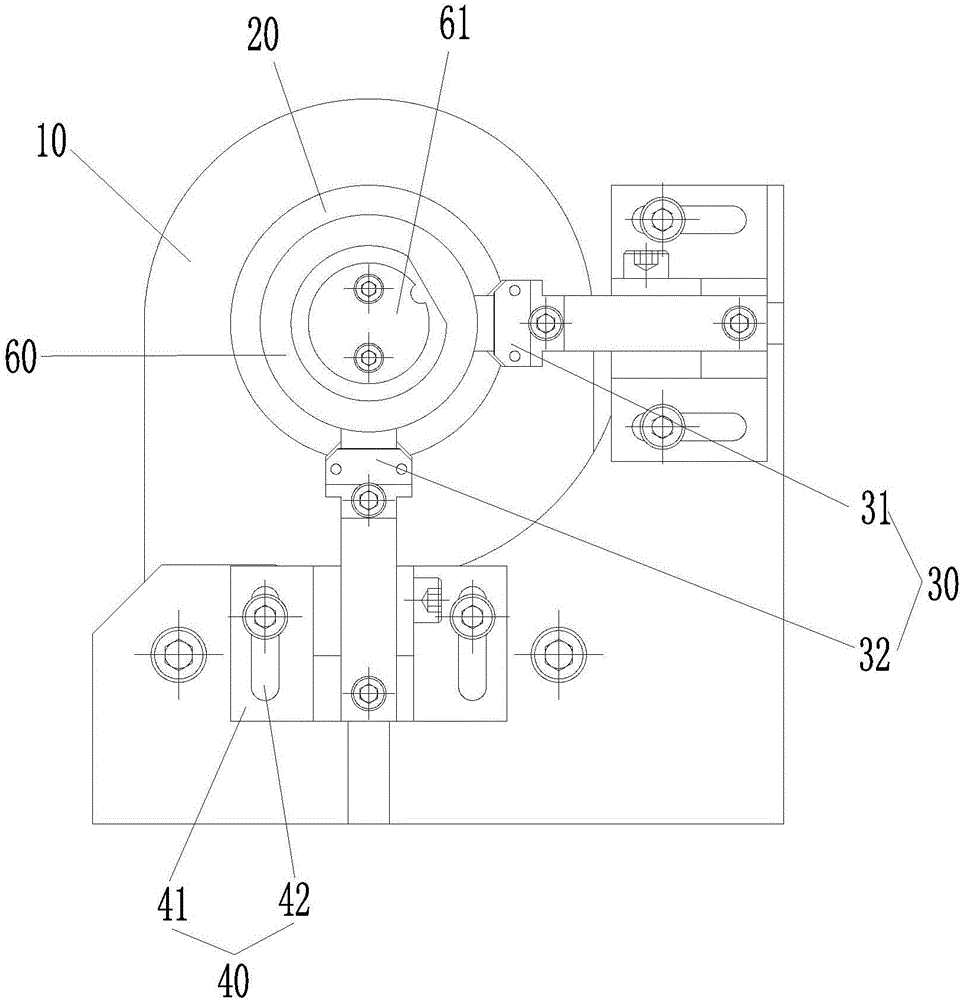

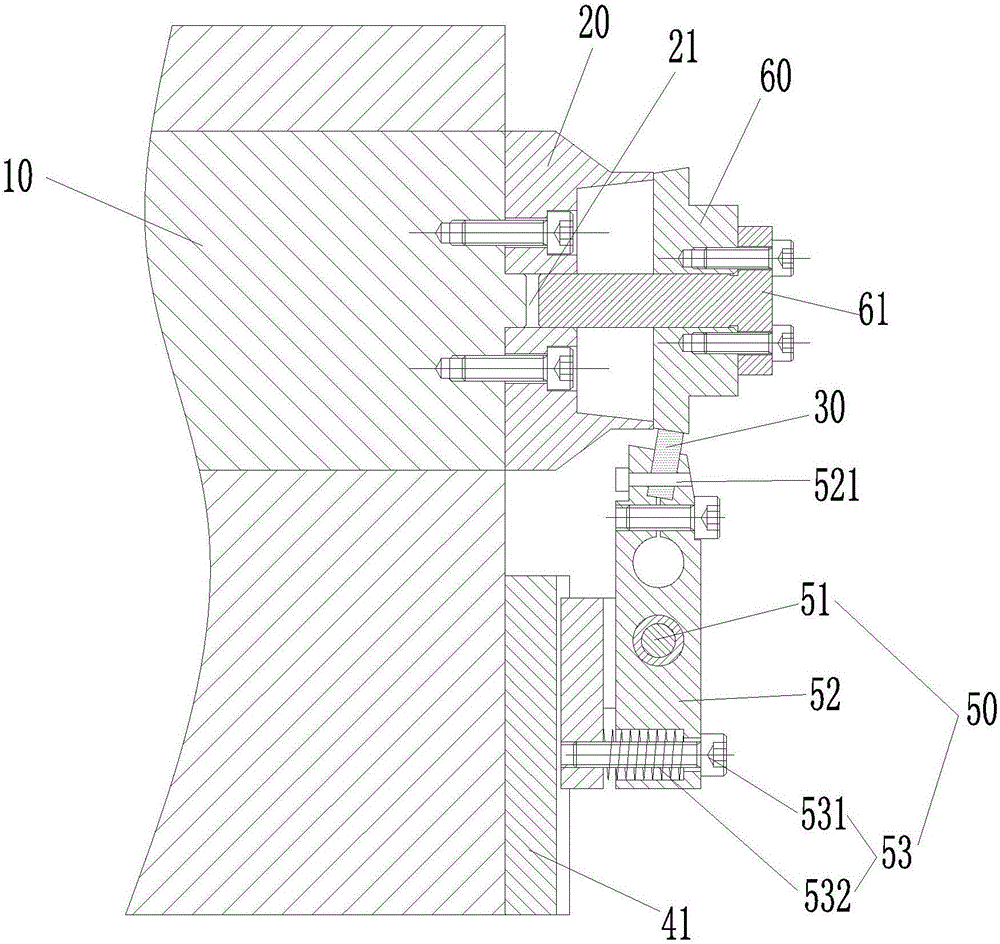

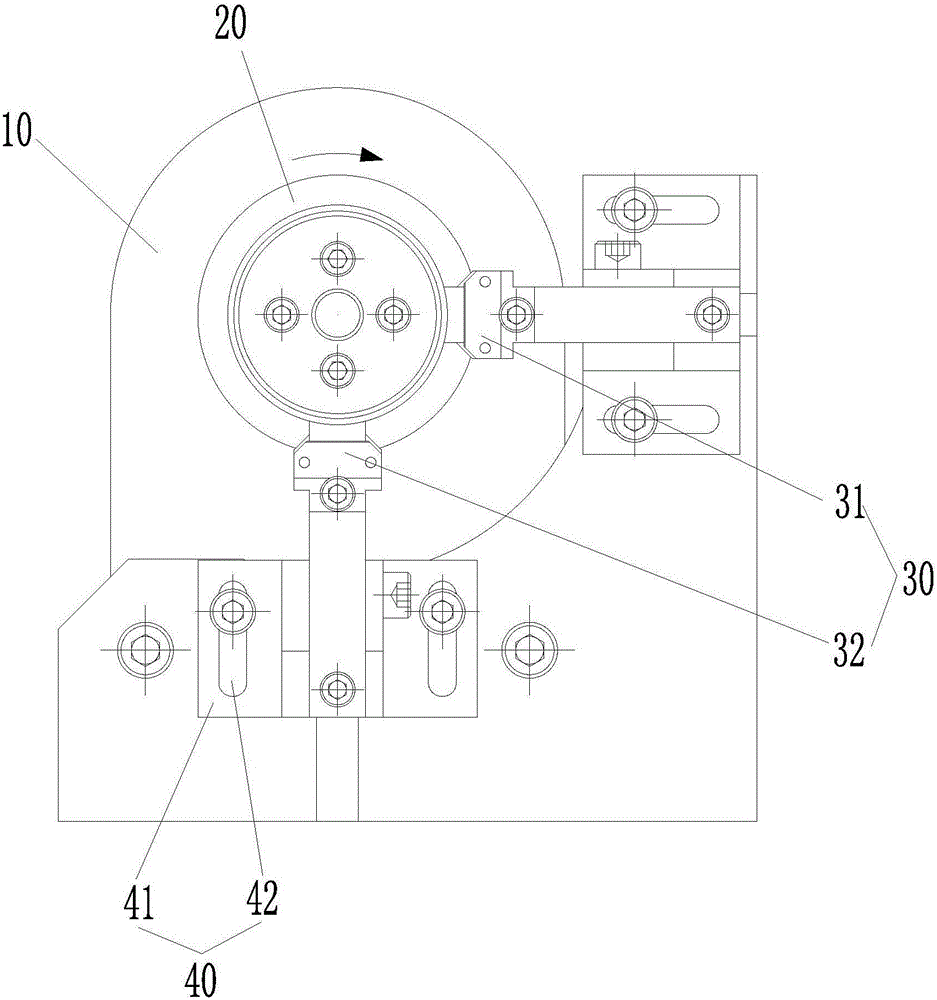

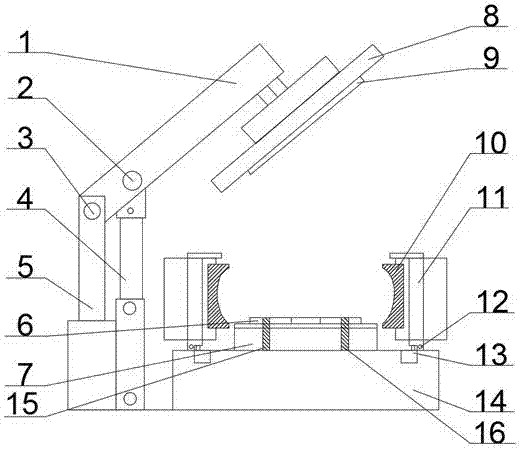

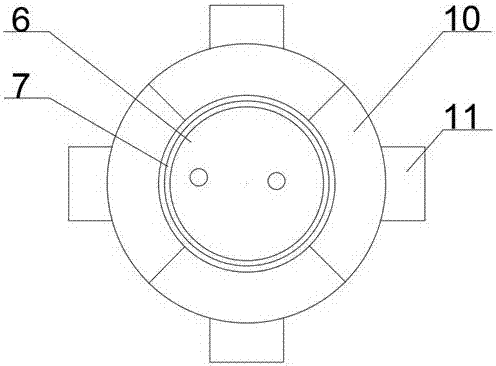

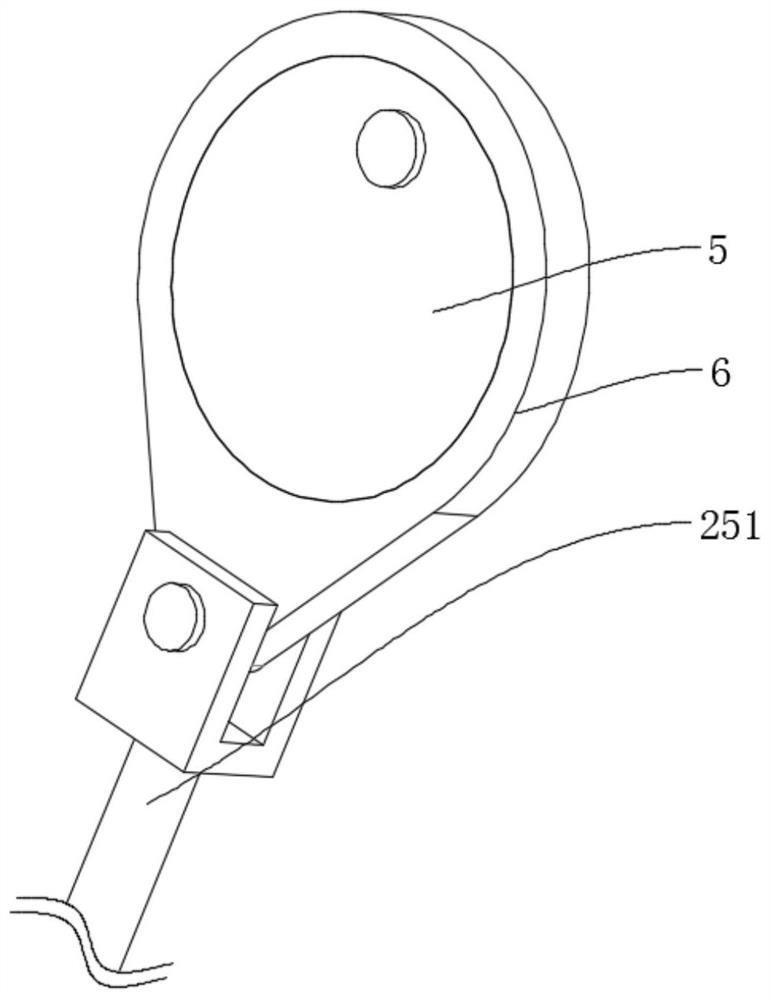

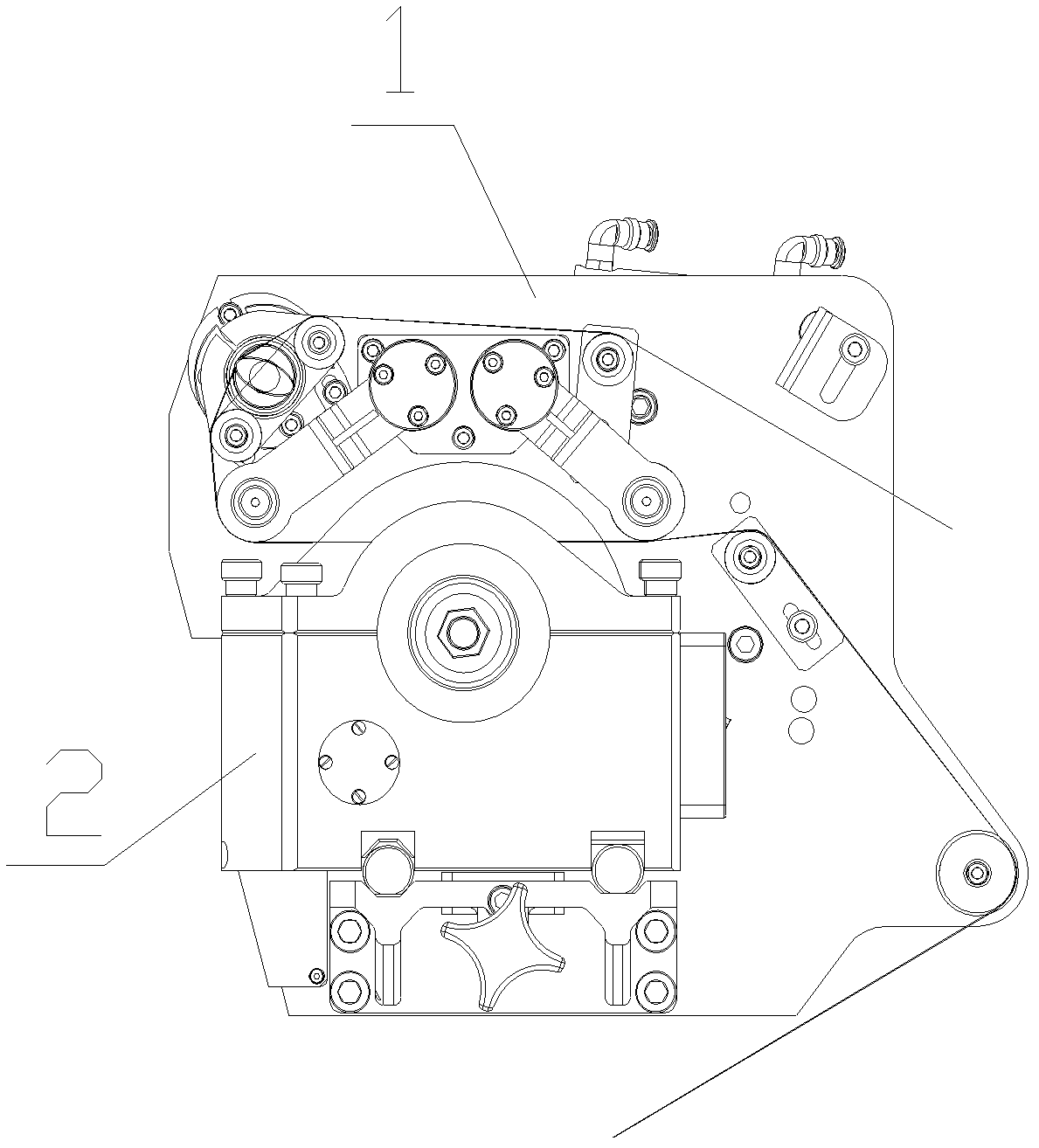

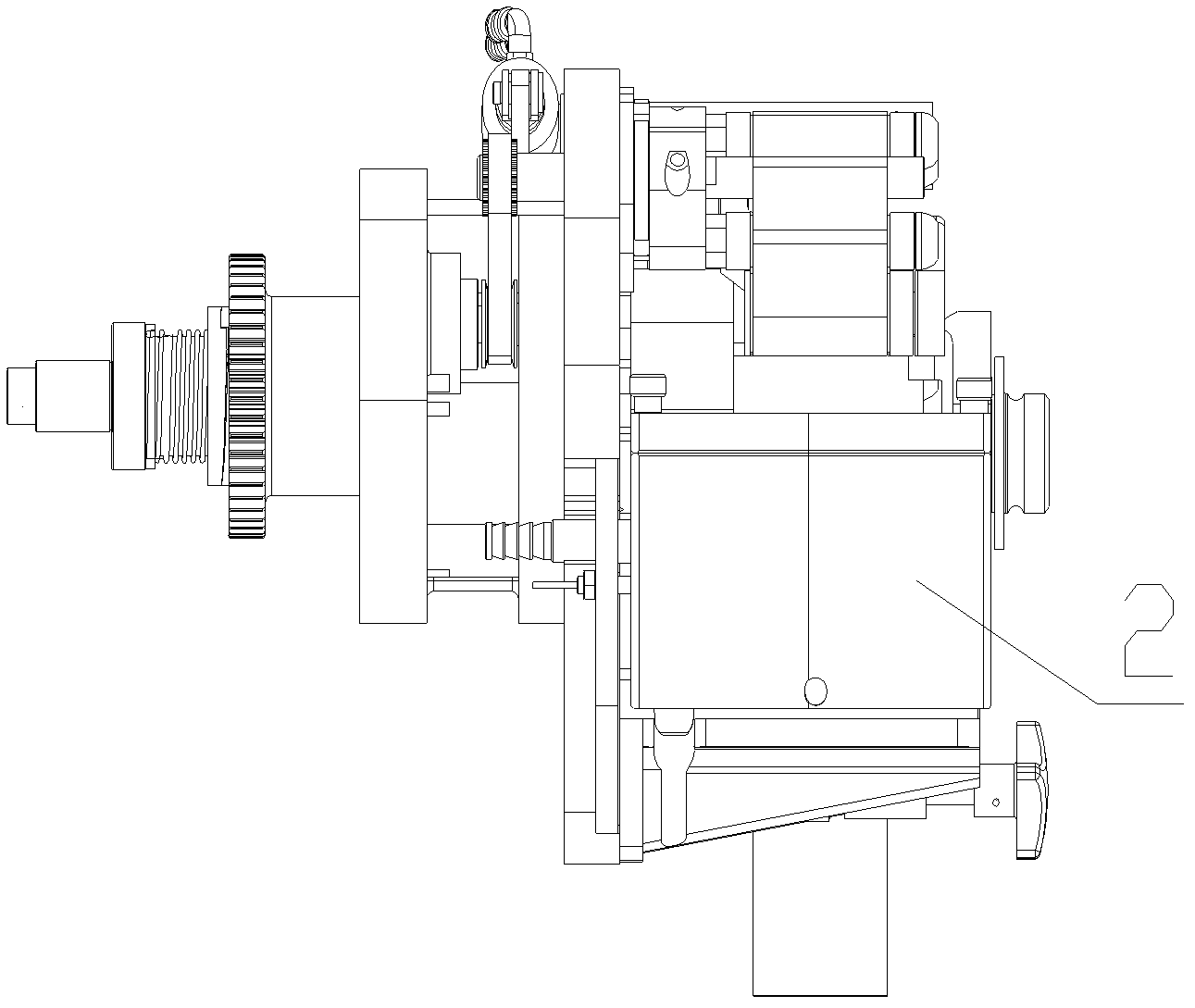

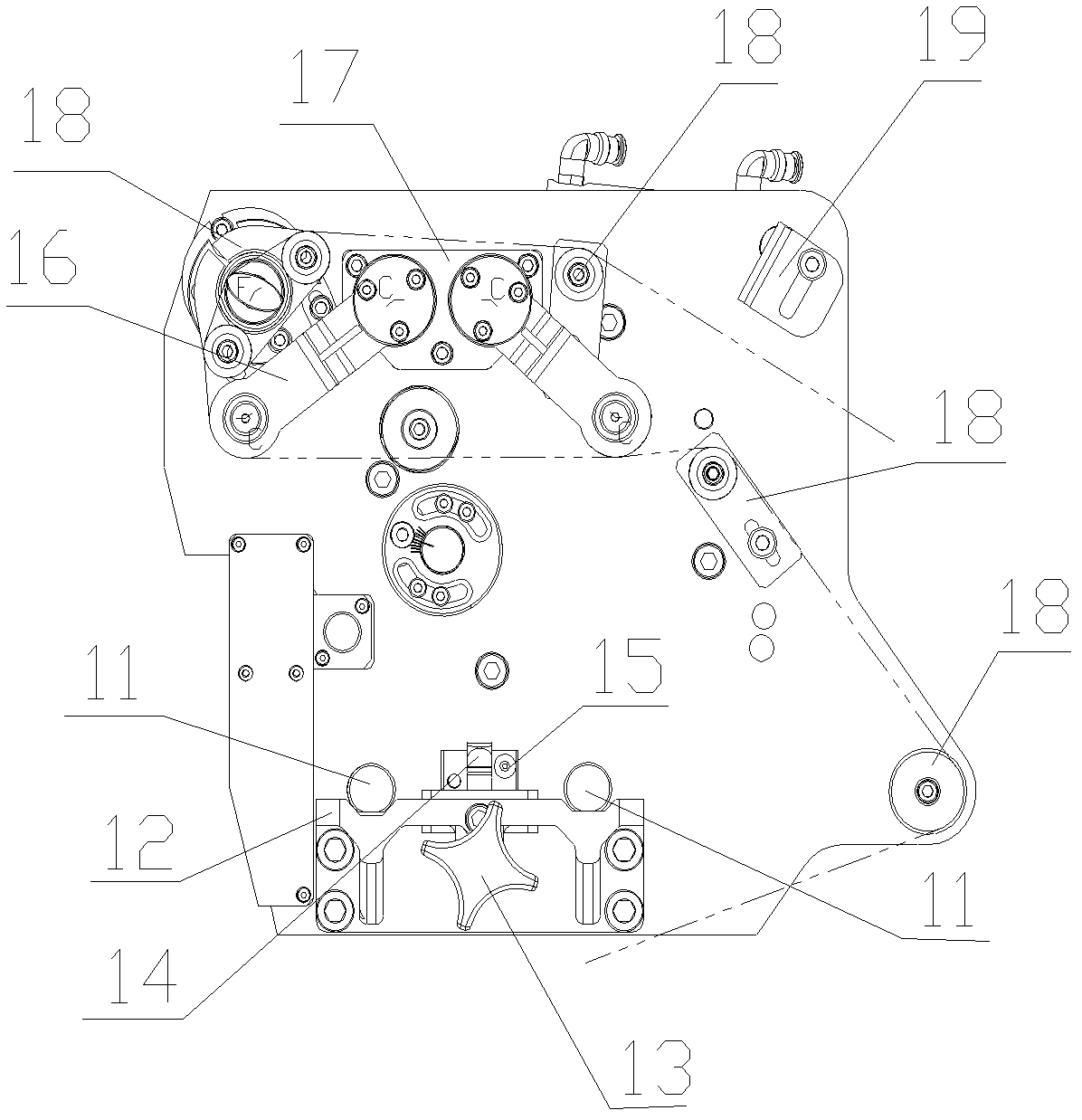

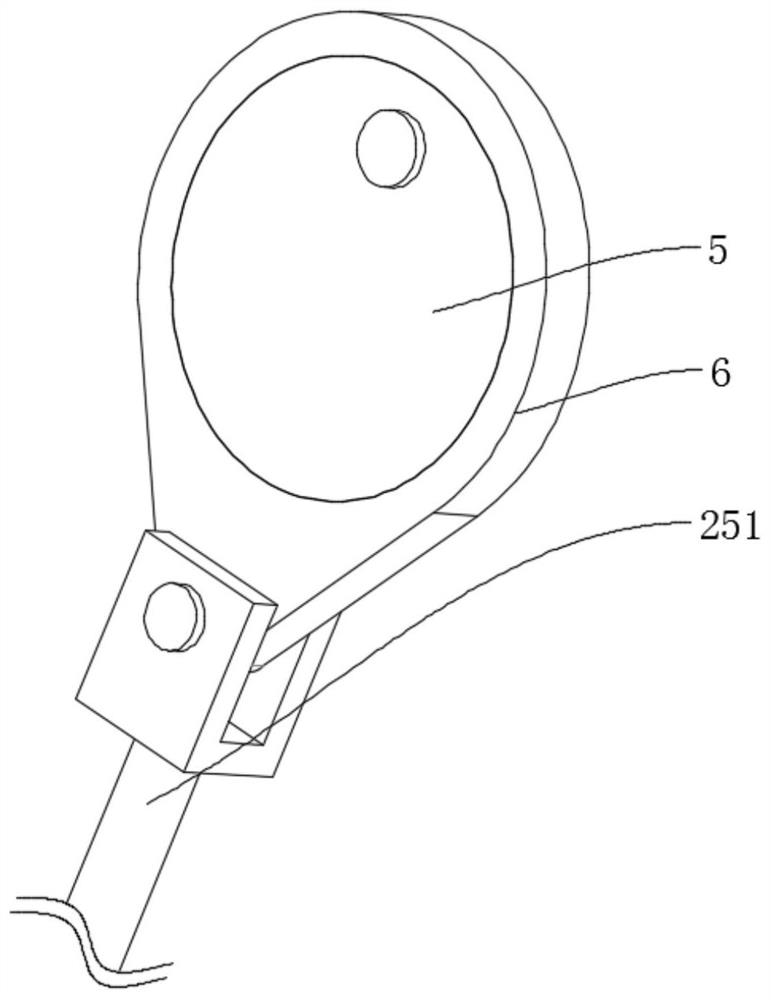

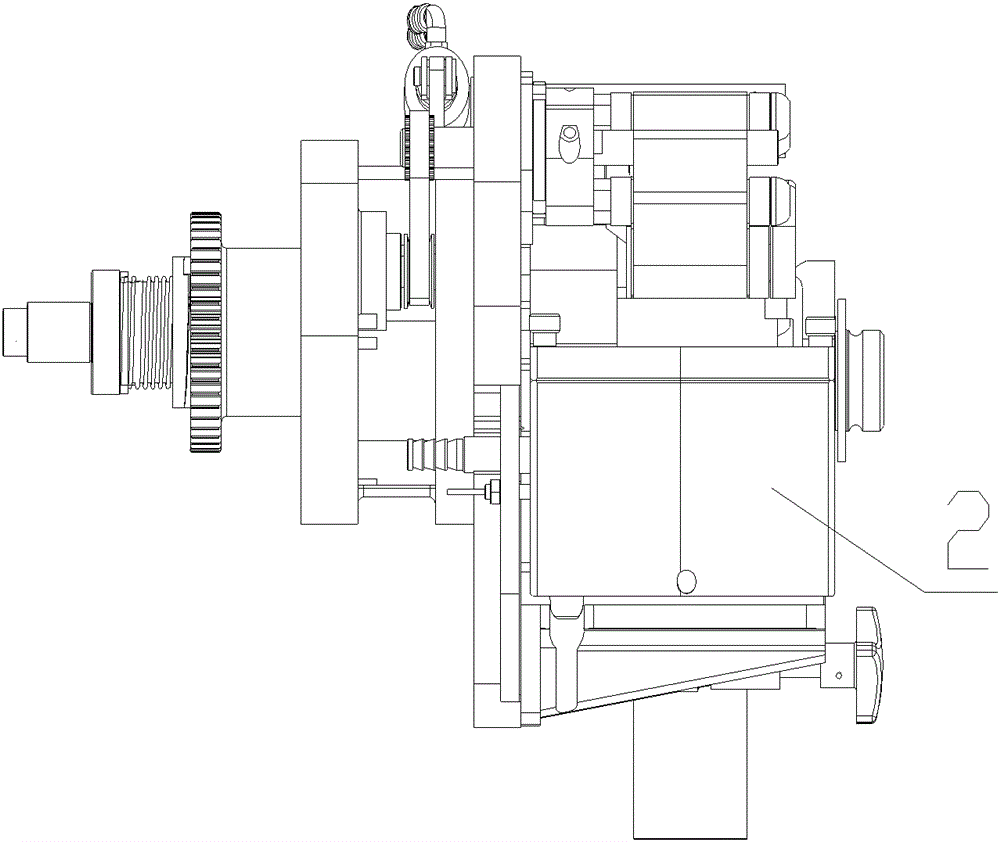

Electromagnetic centerless fixture for conical ring machining and positioning and adjusting tool technique thereof

InactiveCN106112631AReduce non-conformitiesGuaranteed stabilityPositioning apparatusMetal-working holdersCircular coneMachining

The invention discloses a shoe-type centerless fixture for processing a cone ring and its positioning adjustment tooling technology. The support block is movable and set in a machine clamp mode, so that the support surface of the support block can be adjusted radially relative to the workpiece installation area, so that the The crawler type centerless fixture for cone ring processing can process workpieces of various specifications and sizes, and the angle adjustment of the supporting surface of the supporting block can be adjusted clockwise or counterclockwise. Through the adjustment of the angle, the supporting surface can be fully aligned with the outer conical surface of the workpiece. fit, so as to reduce the adhesive wear of the outer cone surface between the support surface and the workpiece and cause the unqualified phenomenon of the workpiece. Further, before processing the workpiece, the positioning body is used to pre-adjust the centerless clamp for cone ring processing. The eccentric direction and eccentric distance between the workpiece of the specified size and the workpiece spindle on the fixture ensure the stability of the workpiece during the grinding process.

Owner:WUHAN KYOWA SYNCHRONIZER RING

Inert gas shielded welding process of aluminum alloy thick plate with thickness being over 12 mm

InactiveCN104439644AQuality improvementReduce non-conformitiesShielding gas supply/evacuation devicesWelding/cutting media/materialsTemperature controlThick plate

The invention discloses an inert gas shielded welding process of an aluminum alloy thick plate with the thickness being over 12 mm. The inert gas shielded welding process is characterized in that the process includes the following steps that (1) an aluminum alloy portion to be welded is machined into a Y-shaped groove or a double-V-shaped groove, a butt-joint connector mode is adopted, the machined groove or the two side surfaces of the groove are polished and cleaned; (2) preheating before welding is conducted on the aluminum alloy plate to be welded, the preheating temperature ranges from 80 DEG C to 100 DEG C, the preheating time ranges from 3 minutes to 5 minutes, and the interpass temperature is controlled in the range of from 110 DEG C to 130 DEG C; (3) inert gas shielded welding is adopted, and welding process parameters are selected; an ER5356 welding wire with the diameter being 4 mm is selected, the arc voltage ranges from 20 V to 22 V, the current ranges from 140 A to 150 A, the welding speed ranges from 400 mm / min to 500 mm / min, and the gas flow ranges from 12 L / min to 15 L / min; (4) in the welding process, a plurality of layers and steps of welding are adopted, and then natural cooling is conducted after welding. By means of the welding process, the welding process procedure can be conducted under the effective control, stability of the overall process and product quality can be guaranteed, the phenomenon of unqualified products is reduced, welding efficiency is high, and the welding defect rate is low.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

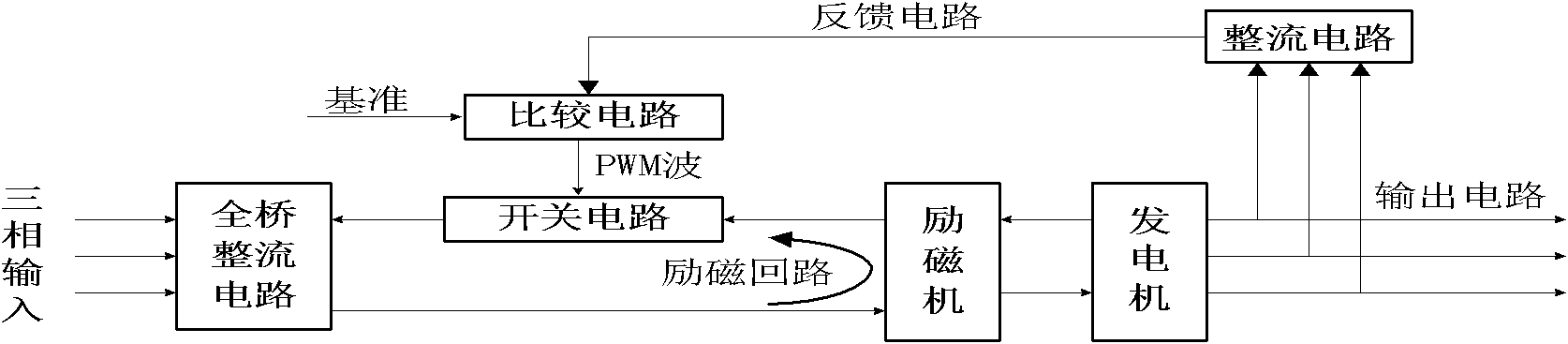

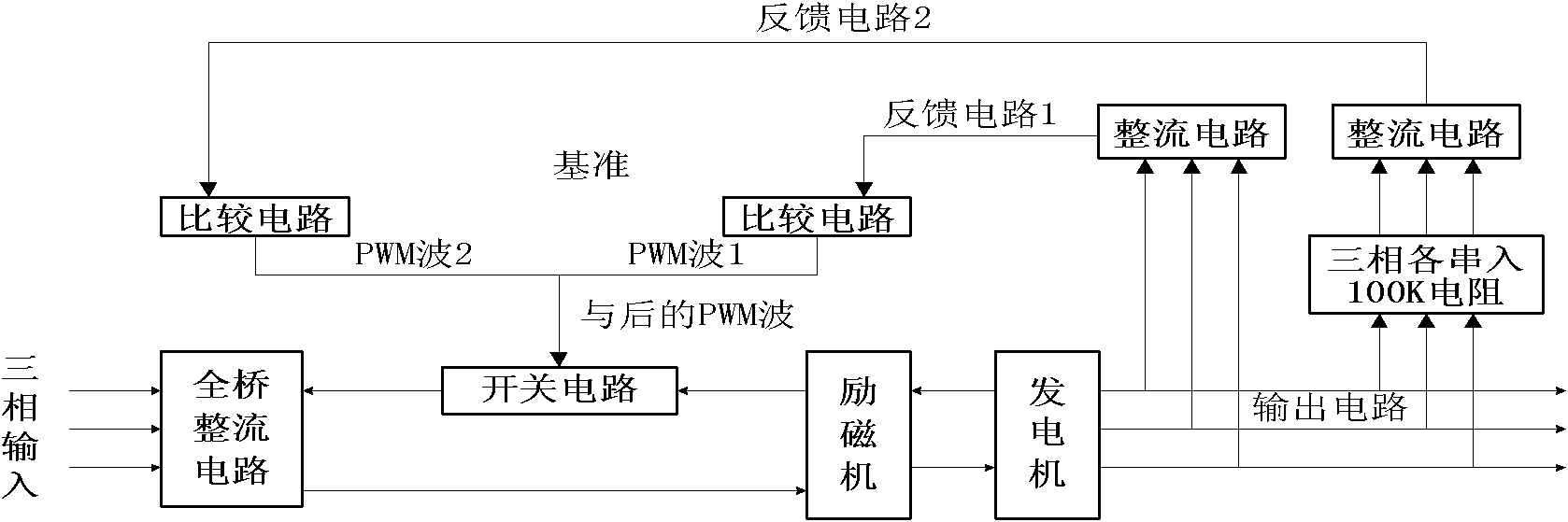

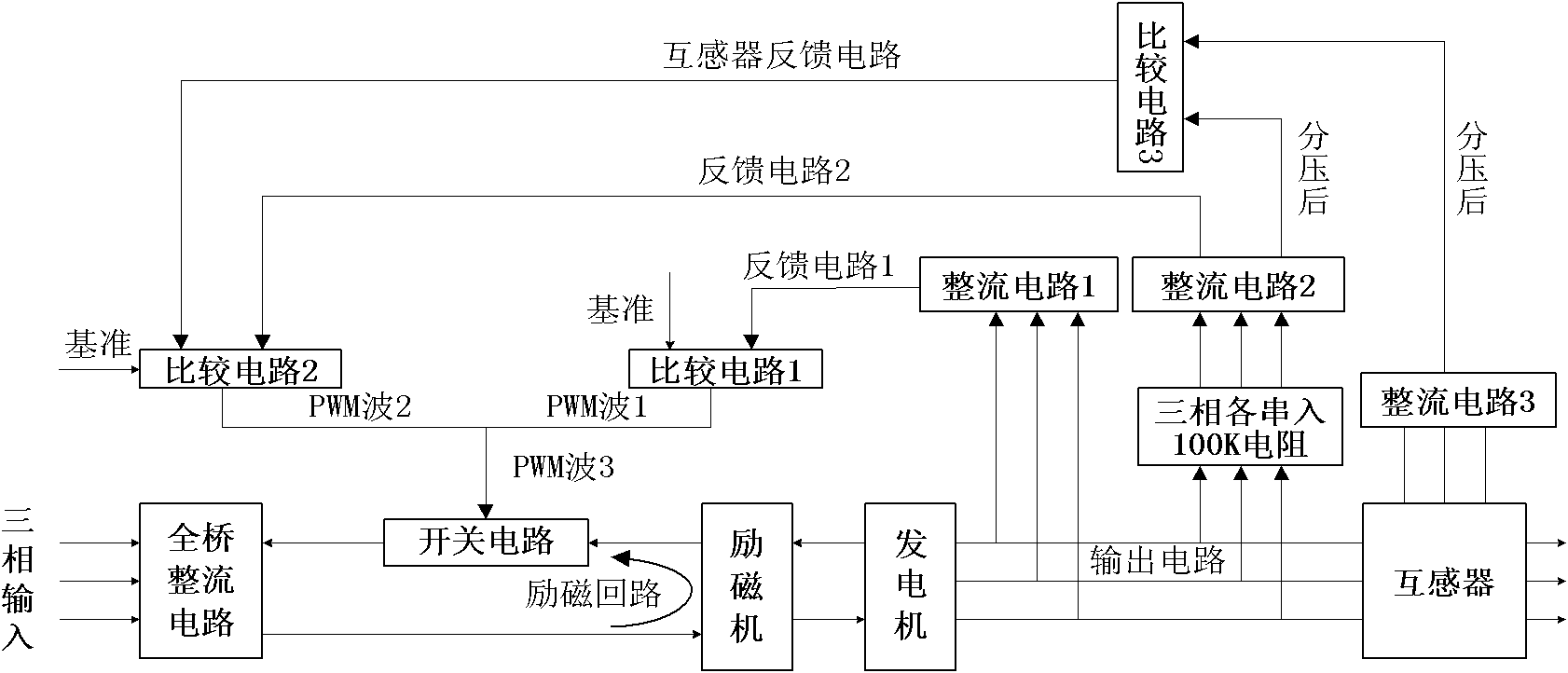

Multifunctional voltage regulation module

ActiveCN101847962AFunction increaseImprove performance indicatorsEmergency protective circuit arrangementsGenerator control by field variationVoltage regulationClosed loop

The invention relate to a multifunctional voltage regulation module which integrates voltage regulation, high-phase restriction, overcurrent protection, digital protection interface and voltage regulation prohibition functions as a whole; and the voltage regulation, high-phase restriction, overcurrent protection, digital protection interface and voltage regulation prohibition functions are realized by corresponding closed-loop voltage regulation and increasing circuits of high-phase restriction, current protection, digital protection and voltage regulation prohibition. The invention has the advantages of highly-integrated functions, increases the high-phase restriction, current protection, digital protection interface and voltage regulation prohibition functions and improves the reliability of a generator controller of an aircraft power system.

Owner:AVIC NO 631 RES INST

Preparation method for low-smoke halogen-free flame retardant material

The invention belongs to the technical field of the synthesis of composite materials and in particular relates to a preparation method for a low-smoke halogen-free flame retardant material. The preparation method for the low-smoke halogen-free flame retardant material comprises the following steps of: dehydrating aluminum hydroxide and enabling the dehydrated aluminum hydroxide to be compatible with a silane coupling agent to obtain a flame retardant; heating up and kneading the flame retardant, EVA (Ethylene-Vinyl Acetate) and other auxiliaries until the materials are heated up to 135 DEG C to 145 DEG C; extruding the kneaded material through a double-screw extruder and a single-screw extruder in sequence; and pelletizing by using an air-cooling mould surface to prepare the low-smoke halogen-free flame retardant material. According to the preparation method disclosed by the invention, the aluminum hydroxide particles can be enabled to be fully compatible with the EVA by adjusting the raw material ratio of the flame retardant material and controlling the temperature in the kneading process and the extruding process, so that the adding amount of the aluminum hydroxide is reduced and the flame retardant effect is ensured. Meanwhile, the pollution of the aluminum hydroxide dust is greatly reduced, the cross-linking reaction of the flame retardant and auxiliaries is more complete, and the strain rate, the elongation at break and the ageing resistance of the halogen-free flame retardant material are further improved.

Owner:HANGZHOU RONGRONG OPTICAL CABLE MATERIALS CO LTD

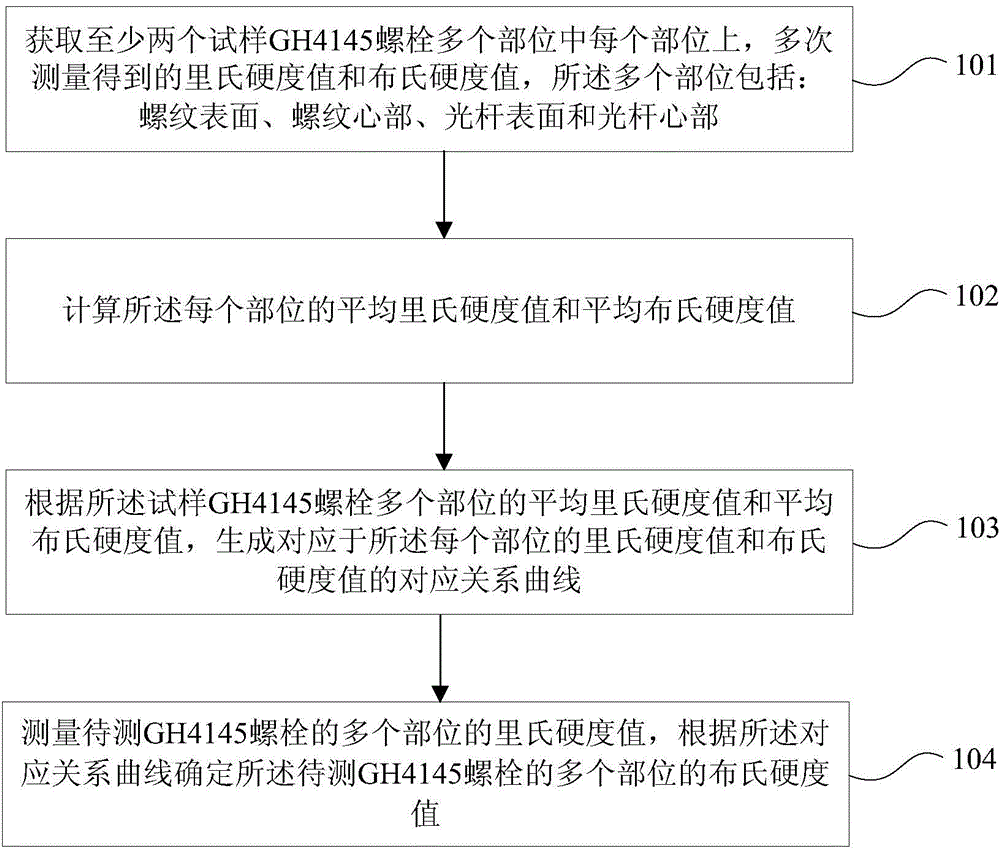

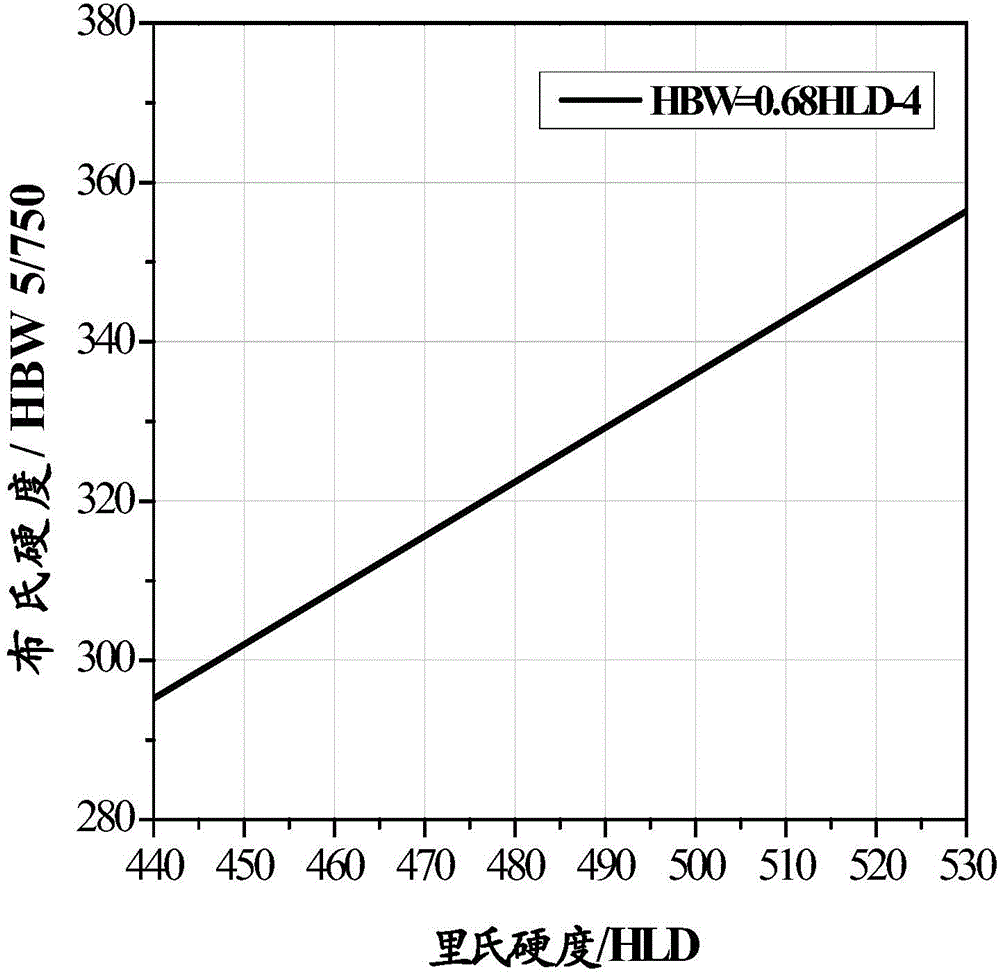

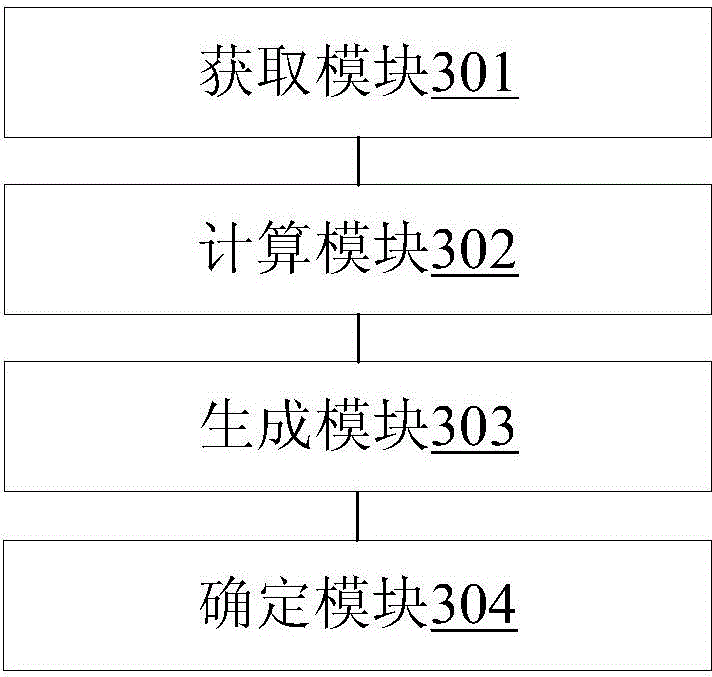

GH4145 bolt Brinell hardness value determination method and apparatus

The embodiment of the present invention provides a method and device for determining the Brinell hardness value of GH4145 bolts, the method comprising: obtaining the Leeb hardness values obtained by multiple measurements on each of the multiple parts of at least two sample GH4145 bolts and Brinell hardness value, multiple parts include: thread surface, thread core, polished rod surface and polished rod core; calculate the average Leeb hardness value and average Brinell hardness value of each part; according to the sample GH4145 bolt multiple parts The average Leeb hardness value and the average Brinell hardness value generate a corresponding relationship curve corresponding to each part of the Leeb hardness value and Brinell hardness value; measure the Leeb hardness values of multiple parts of the GH4145 bolt to be tested, according to the corresponding relationship The curve determines the Brinell hardness values of multiple parts of the GH4145 bolt to be tested. This scheme can reduce the deviation that occurs when determining the Brinell hardness value of the GH4145 bolt, reduce the misjudgment rate, and further reduce material waste.

Owner:STATE GRID CORP OF CHINA +3

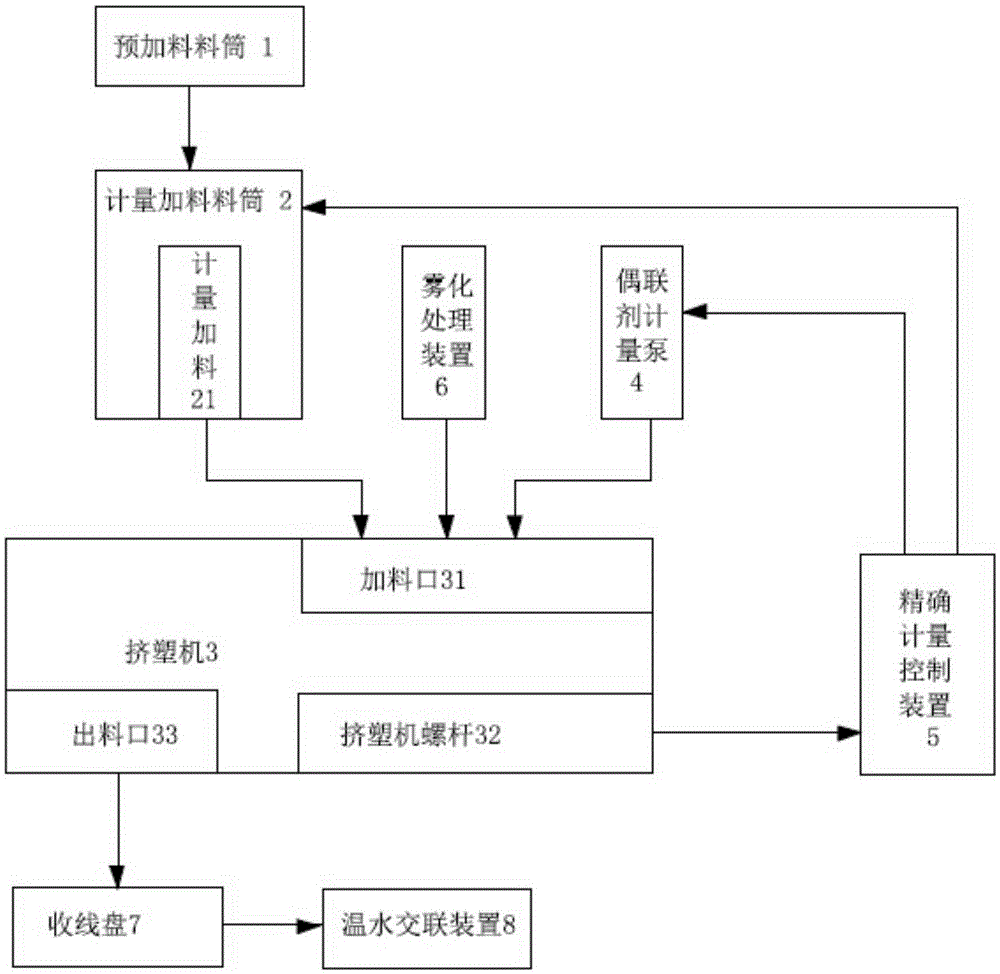

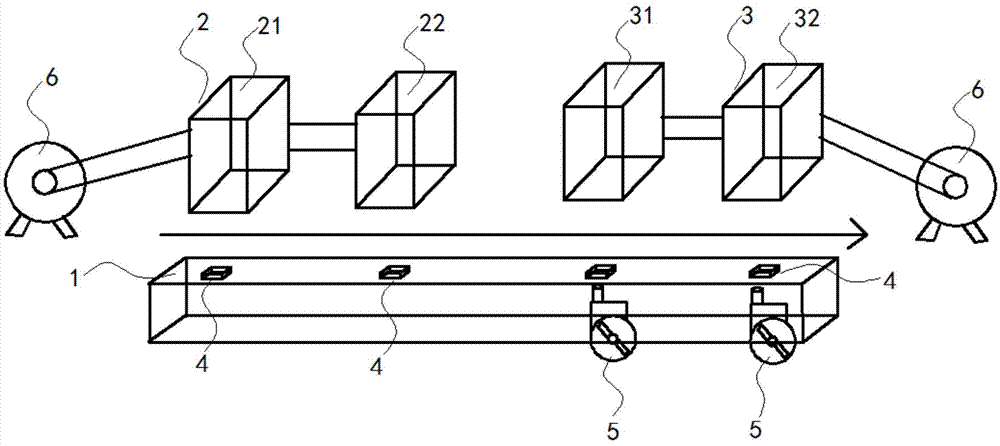

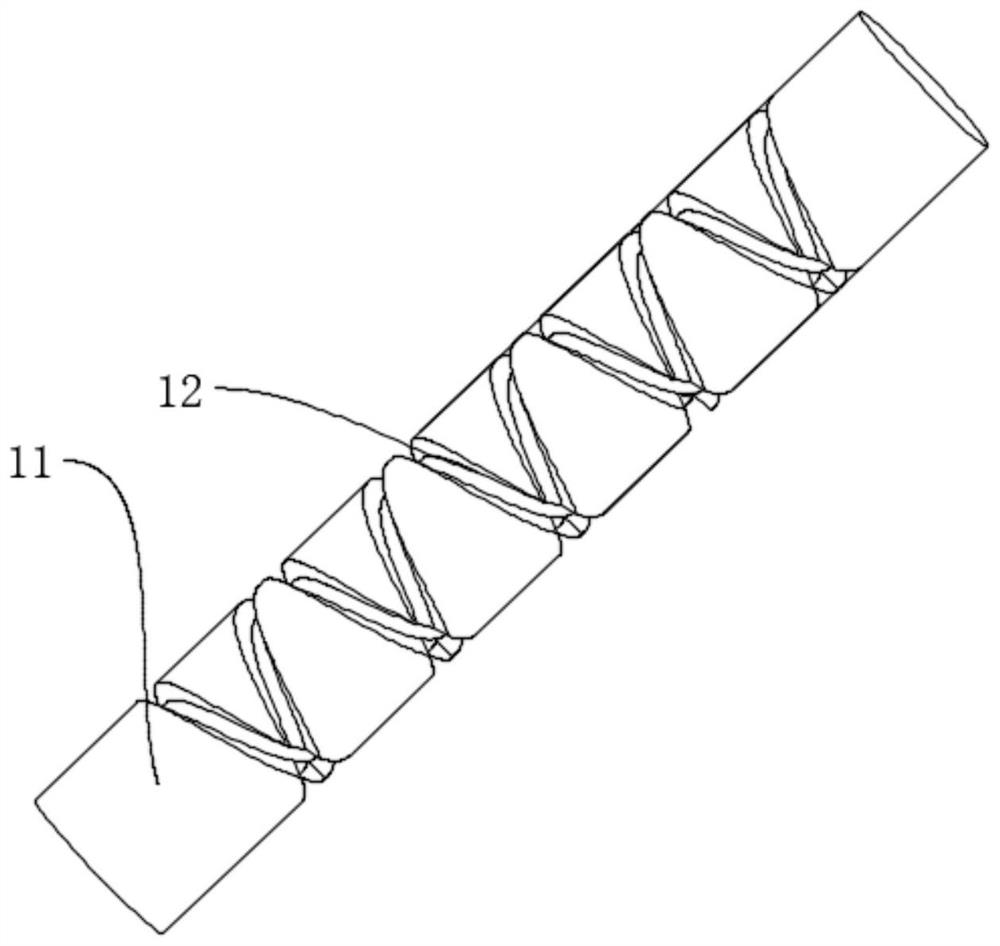

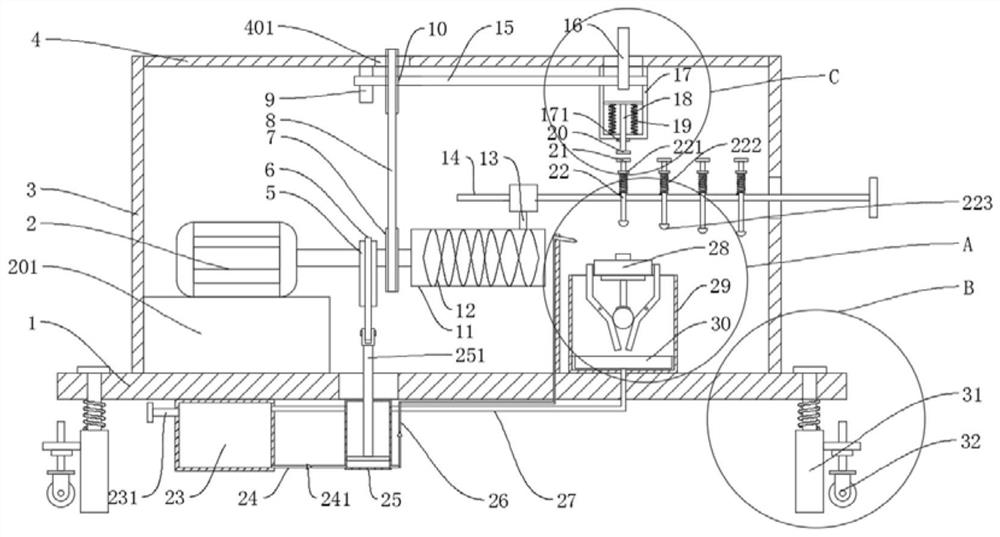

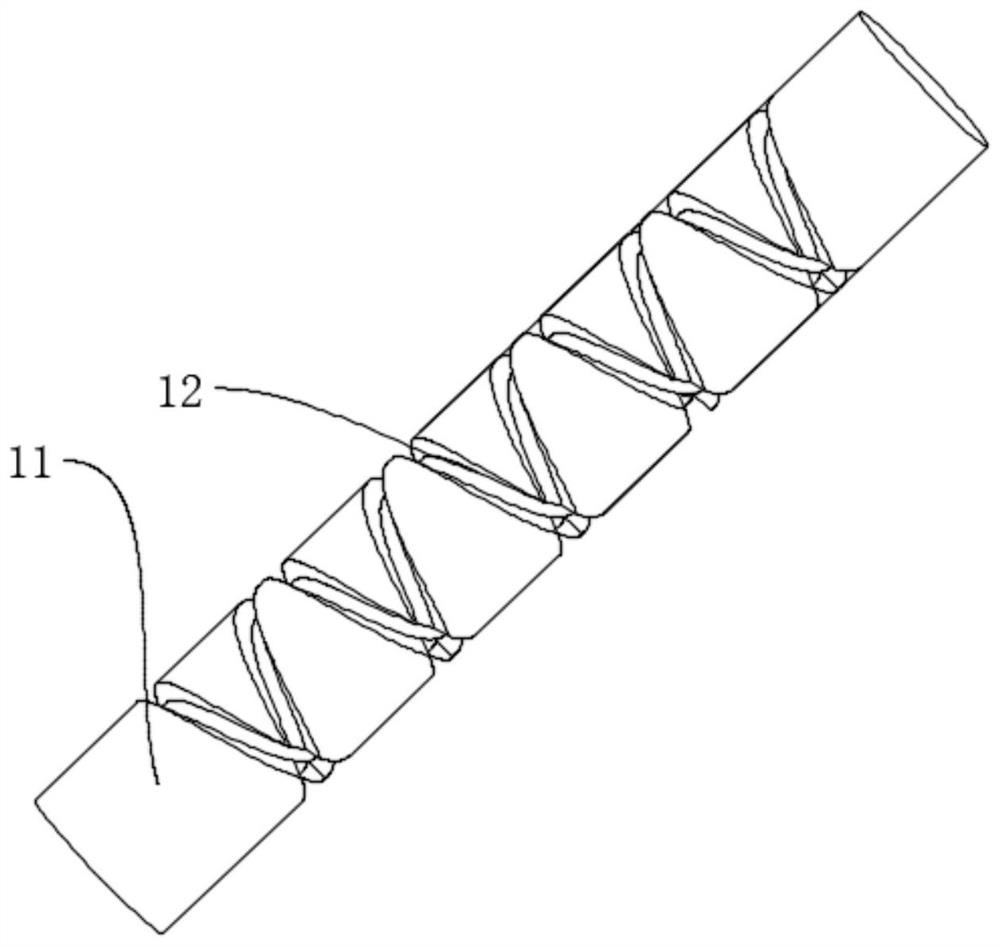

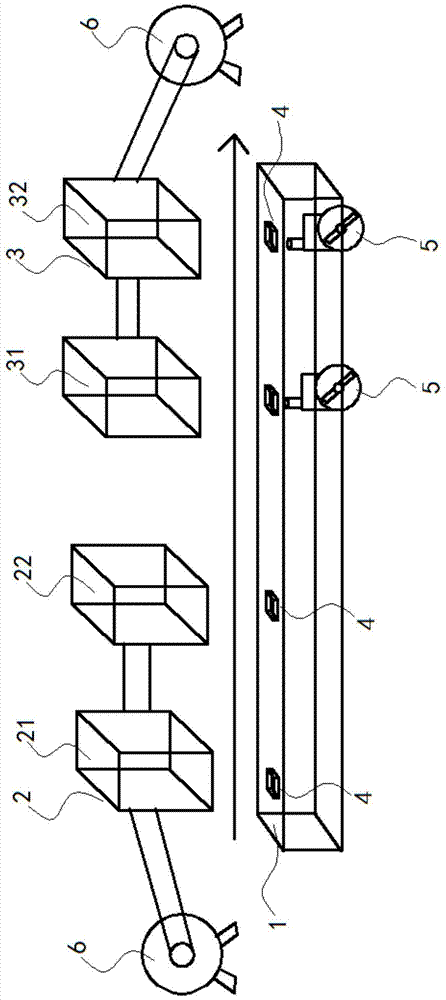

Production device and production process of organosilane crosslinked polyethylene insulated overhead insulation cable in one step

InactiveCN105280314AAccurate measurementReduce manufacturing costInsulating conductors/cablesElectrical conductorMixed materials

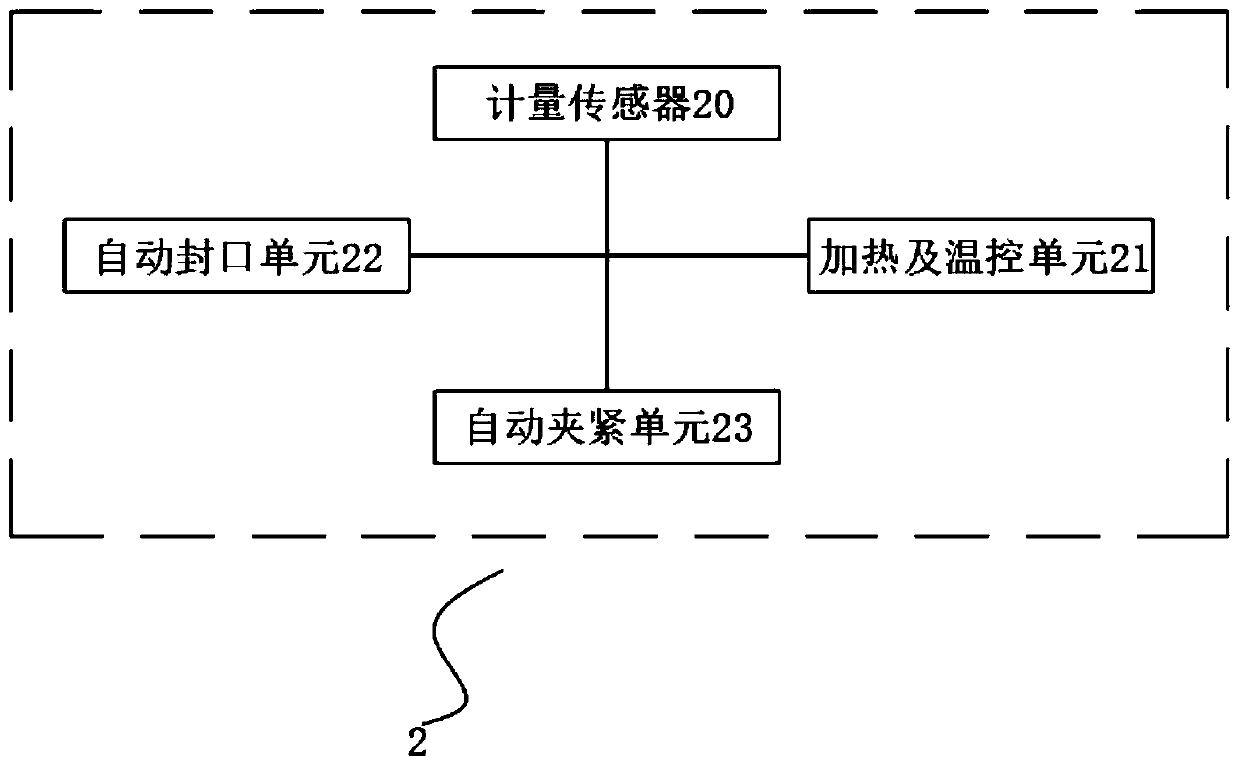

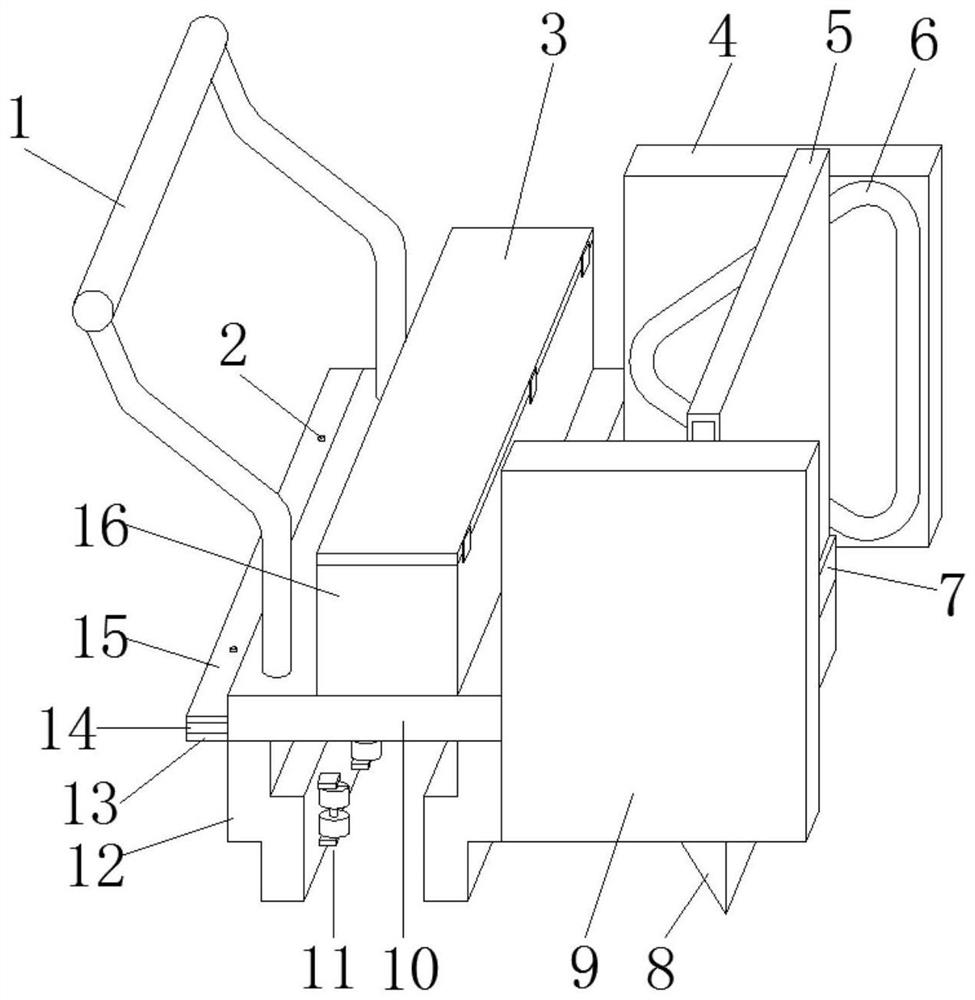

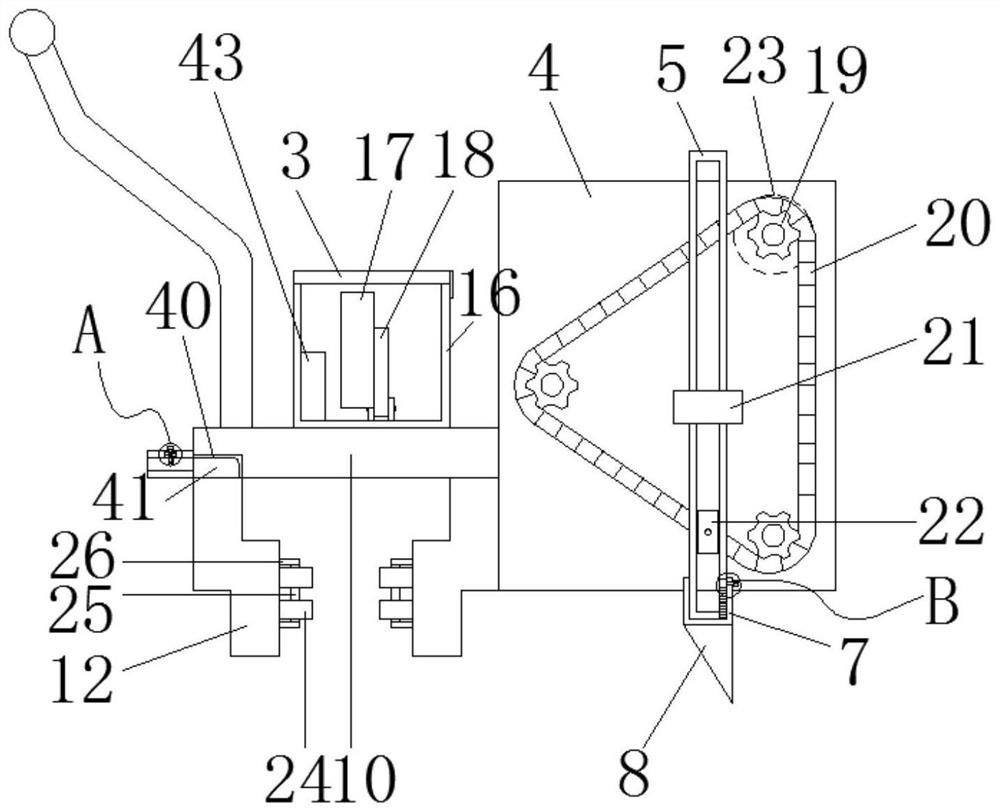

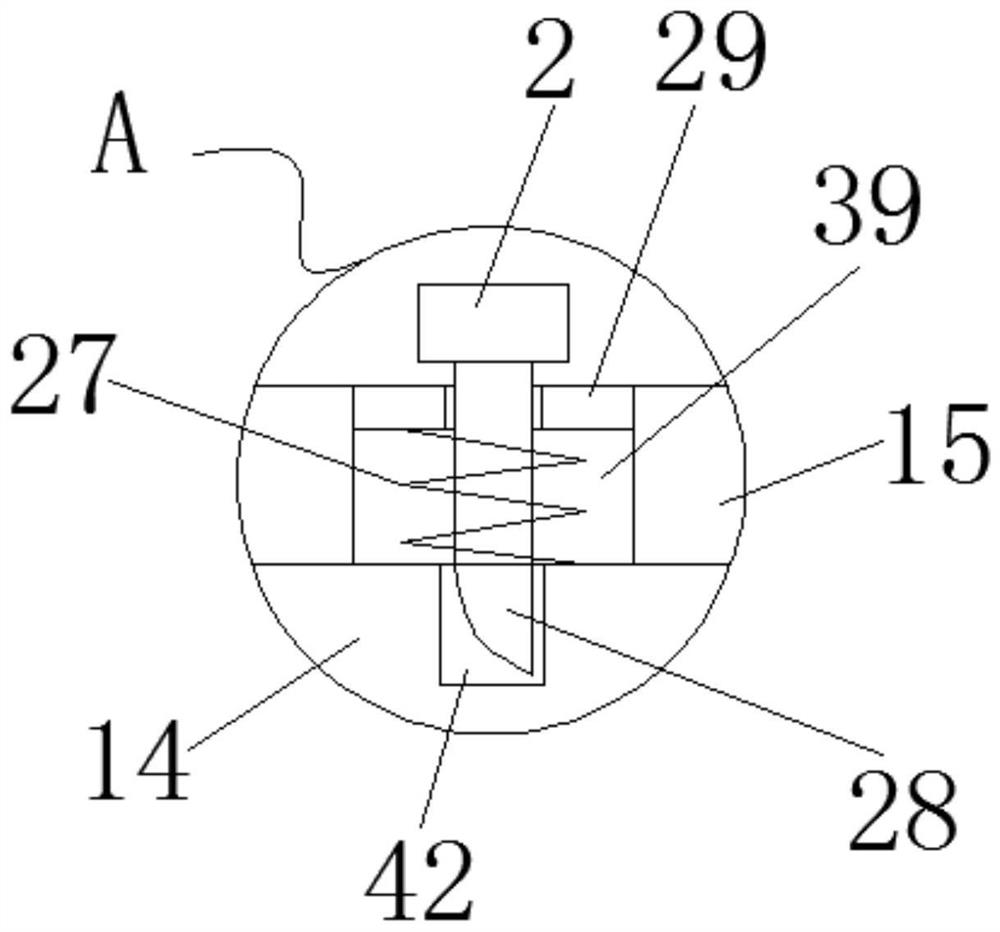

The invention discloses a production device and production process of an organosilane crosslinked polyethylene insulated overhead insulation cable in one step. The production device comprises a pre-feeding cylinder, a metering feeding cylinder, an extruding machine, a coupling agent metering pump and an accurate metering control device, wherein the outlet of the pre-feeding cylinder is communicated with the inlet of the metering feeding cylinder, a metering screw rod is arranged at the outlet of the metering feeding cylinder, the outlet of the metering feeding cylinder is communicated with a feeding hole of the extruding machine, the outlet of the coupling agent metering pump is communicated with the feeding hole of the extruding machine, the accurate metering control device is used for acquiring parameters of an extruding machine screw rod of the extruding machine and feeding back and controlling the output of the metering screw rod of the metering feeding cylinder and the output of the coupling agent metering pump. With the production device disclosed by the invention, the rotational speed of the screw rod of the extruding machine is acquired, a mixed material and a coupling agent are accurately metered, the production and the final extrusion of the insulation material onto a semiconductor can be completed in one time, and the production cost of the organosilane crosslinked polyethylene overhead insulation cable is greatly reduced.

Owner:FAR EAST CABLE +2

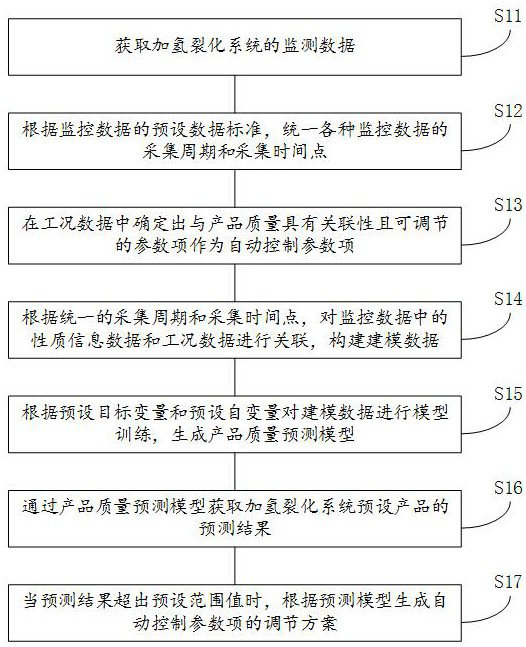

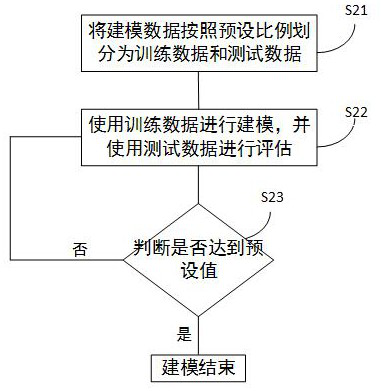

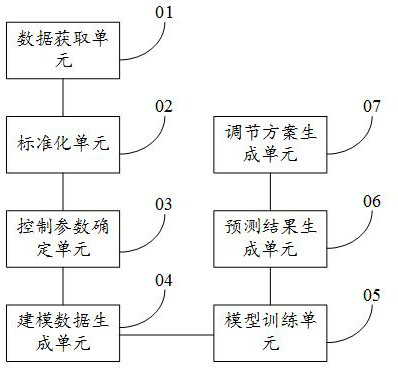

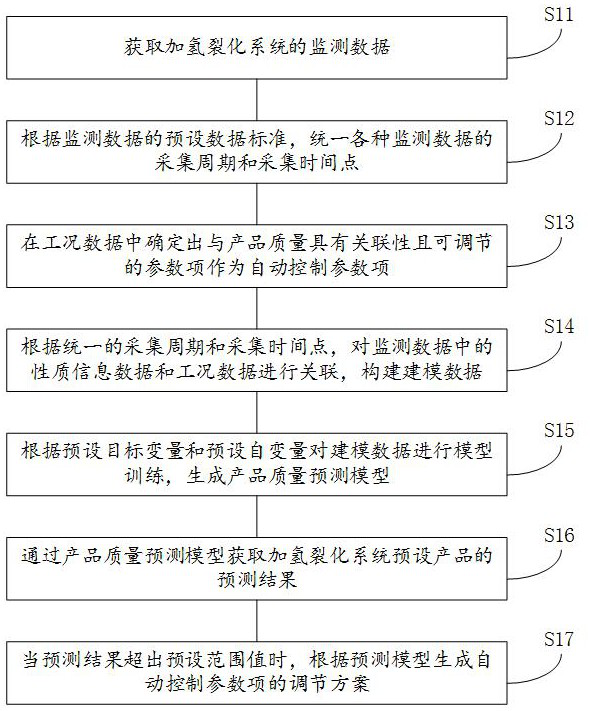

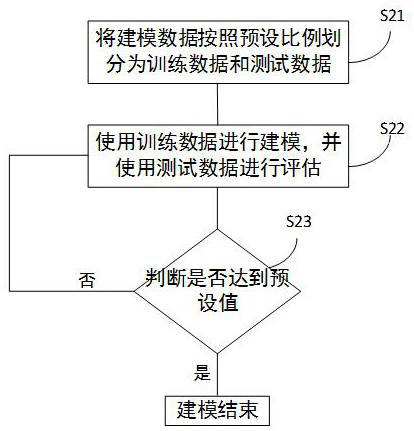

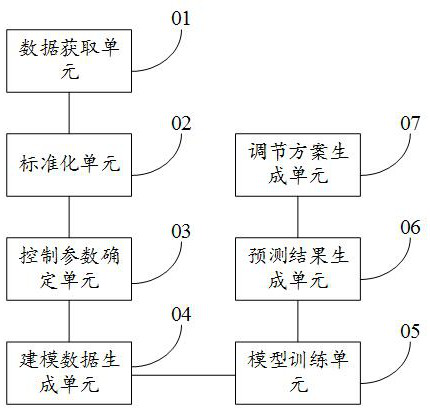

Hydrocracking product quality automatic control method and device and memory

ActiveCN111849544AReduce non-conformitiesReduce the problem of low quality modeling dataCharacter and pattern recognitionHydrocarbon oil crackingAutomatic controlProcess engineering

The invention discloses a hydrocracking product quality automatic control method and device and a memory. The hydrocracking product quality automatic control method comprises the following steps: acquiring monitoring data of a hydrocracking system; unifying acquisition periods and acquisition time points of various monitoring data according to a preset data standard of the monitoring data; determining adjustable parameter items related to the product quality in the working condition data as automatic control parameter items; constructing modeling data; performing model training on the modelingdata according to a preset target variable and a preset independent variable to generate a product quality prediction model; taking key parameter items determined from the real-time monitoring data as input, and obtaining a prediction result of a preset product of the hydrocracking system through a product quality prediction model; and when the prediction result exceeds the preset range value, generating an adjustment scheme of the automatic control parameter item according to the prediction model. According to the invention, the working condition of the hydrocracking device can be kept in areasonable running state so that the condition that the product quality is unqualified can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

TIG ((tungsten inert gas) welding process of less than 3mm thick aluminum and aluminum alloys

InactiveCN104493338AQuality improvementReduce non-conformitiesArc welding apparatusWelding/cutting media/materialsButt weldingShielding gas

The invention discloses a TIG ((tungsten inert gas) welding process of less than 3mm thick aluminum and aluminum alloys. The process includes the steps of performing butt welding, and making an I-shaped groove at a welding joint; attaching a protective film to a plate before welding; performing TIG welding, and setting welding process parameters, including welding current 100 to 170A, protective gas flow 8 to 12L / min, tungsten electrode diameter 2 to 3mm, welding rod diameter 2 to 3mm, and nozzle diameter 8 to 12mm; allowing two operators to perform manual vertical TIG welding to the outside and inside of a workpiece from bottom to top, respectively. The TIG welding process has the advantages that the process is subjected to effective control, process stability and product quality stability are ensured, fewer unqualified products occur, and the process is suitable for the welding of less than 3mm thick aluminum and aluminum alloys.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

10-12mm plate thickness aluminum and aluminum alloy tungsten inert gas (TIG) welding process

InactiveCN104475938AStable the whole processQuality improvementArc welding apparatusWelding/cutting media/materialsButt weldingShielding gas

The invention discloses a 10-12mm plate thickness aluminum and aluminum alloy tungsten inert gas (TIG) welding process. The welding process is characterized by including the following steps that (1) a to-be-welded end face is cleaned in a mechanism mode, and then the mechanically cleaned surface is carefully wiped by organic solvent or cleaning agent to remove residual organic matters or metal dust; (2) butt welding is applied, a Y-shaped groove is designed at the position of a joint, the groove angle is 55-65 degrees, and the butt joint gap is 1-2mm; (3) TIG welding is applied, and welding process parameters are set, for example, the welding current is 280-300A, the protective gas flow is 16-18L / min, the tungsten electrode diameter is 5mm, the welding wire diameter is 4-5mm, and nozzle hole diameter of a welding gun is 14-16mm; (4) a welded position is preheated, the pre-heating temperature is 90-100 DEG C, and the preheating time is 30-40 seconds; (5) during welding, multi-layer multi-channel continuous welding can be applied, and the temperature among layers is controlled in a range from 170 DEG C to 210 DEG C. According to the 10-12mm plate thickness aluminum and aluminum alloy TIG welding process, the welding process can be performed under effective control, stable whole process and product qualities are guaranteed, and phenomena of unqualified products can be reduced.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

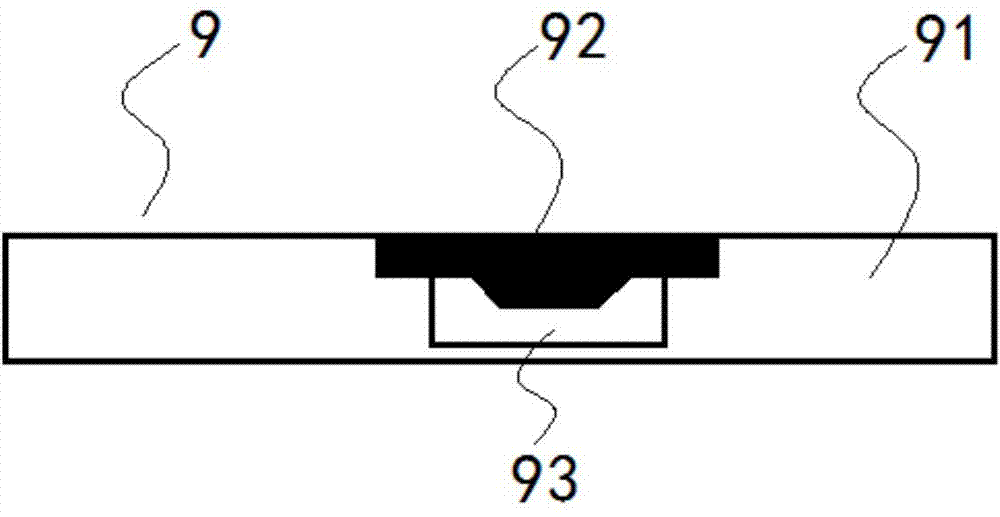

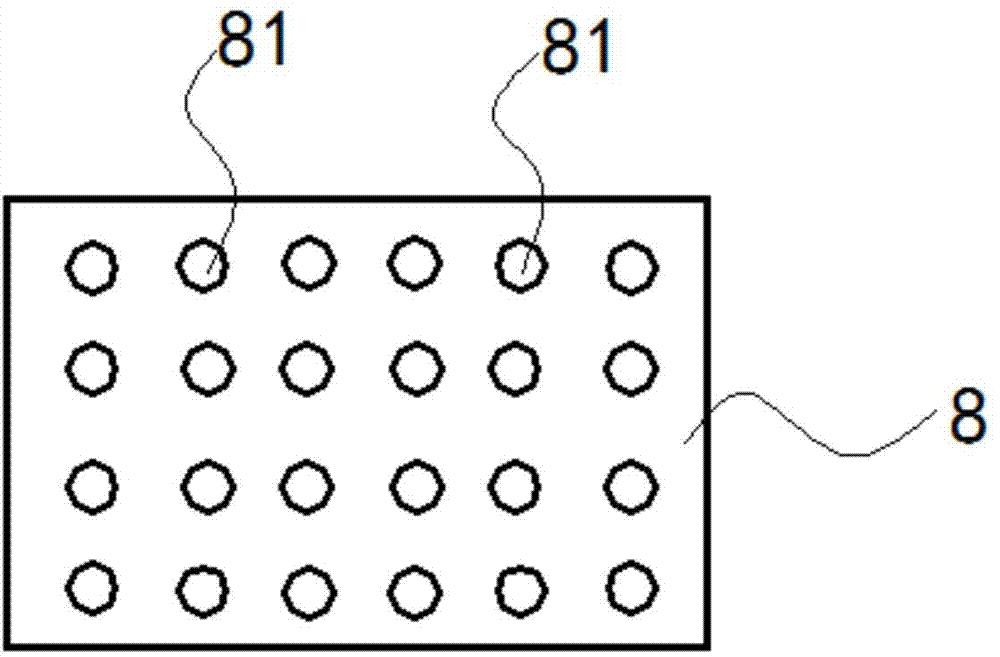

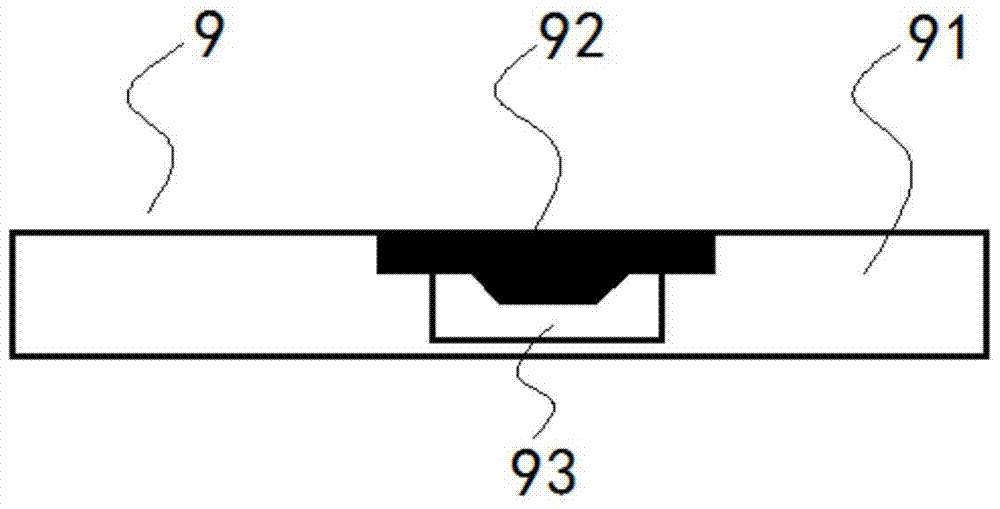

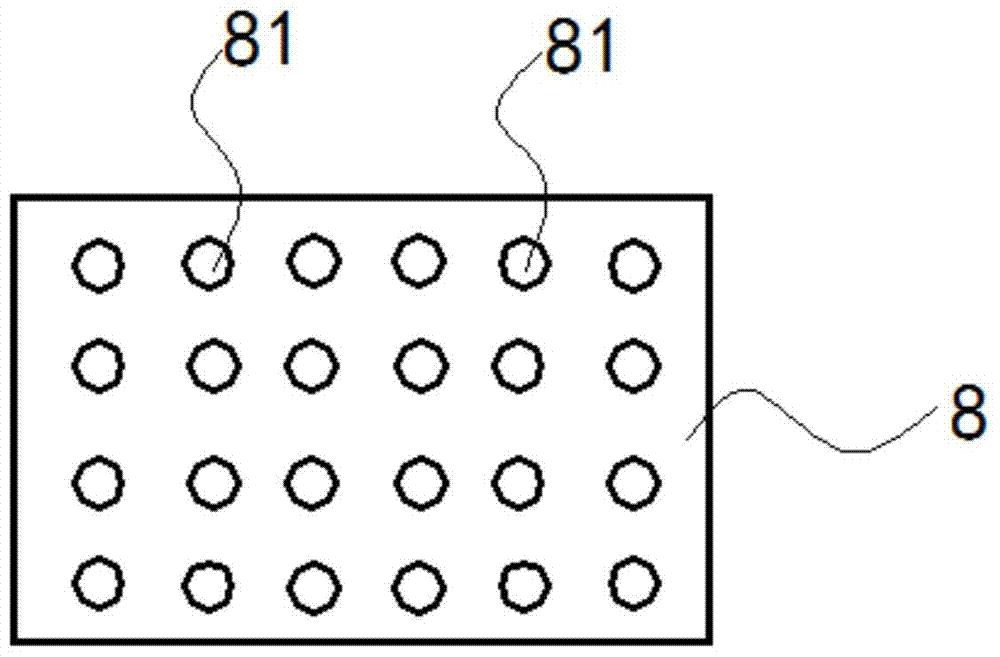

IC card packaging device and method

ActiveCN104733358AKeep it flatImprove aestheticsSemiconductor/solid-state device manufacturingEngineeringHot pressing

The invention discloses an IC card packaging device and method. The IC card packaging device comprises a packaging platform, hot pressing devices, cold pressing devices, negative pressure devices, a transmission device and power devices, wherein the hot pressing devices and the cold pressing devices are sequentially arranged in the IC card transmission direction, the hot pressing devices comprise hot pressing heads, and the hot pressing heads are internally provided with heating devices; the cold pressing devices comprise cold pressing heads, the packaging platform is provided with card grooves adapted to the size of an IC card, the bottom surface of each card groove is provided with adsorption holes, and the negative pressure devices are communicated with the adsorption holes. When the cold pressing heads conduct cold pressing on the IC cards in the card grooves, plastic card bases in the card grooves are absorbed by the adsorption holes through negative pressure, so that the lower surfaces of the plastic card bases in a softening state become regular and flat, and then the beautiful degree of the card surfaces is greatly improved.

Owner:HONGBO CO LTD

Conveniently-produced automobile tire vulcanizing machine

The invention discloses a conveniently-produced automobile tire vulcanizing machine. The machine comprises a base, an upright column and a rotating arm, wherein a lower heating plate is fixed on the base by threads; the lower heating plate is fixed with an upper laminated plate; an air inlet hole and an air outlet hole are symmetrically formed in the middle of the upper laminated plate; a side heating plate and the base are movably connected at the periphery of the lower heating plate; an inner circle of the side heating plate is welded with a movable mould; the left side of the base is fixed with the upright post by threads; the upper end of the upright post is movably connected with a rotating arm; the right side of the upright post is welded and fixed with a rotating arm oil cylinder; the rotating arm oil cylinder is movably connected to the rotating arm; the tail end of the rotating arm is fixed with an upper heating plate; and the lower surface of the upper heating plate is fixed with an upper laminated plate by threads. The conveniently-produced automobile tire vulcanizing machine is simple in structure, is convenient to use and is safe to operate; due to multi-directional plate, the tire can be heated in a vulcanizing process more quickly and uniformly; and the movable block is formed by the movable mould, the upper heating plate, the side heating plate and the lower heating plate, so that the operation of vulcanizing steps can be simplified, and the manufacturing cost is reduced.

Owner:盐城易宝路轮胎有限公司

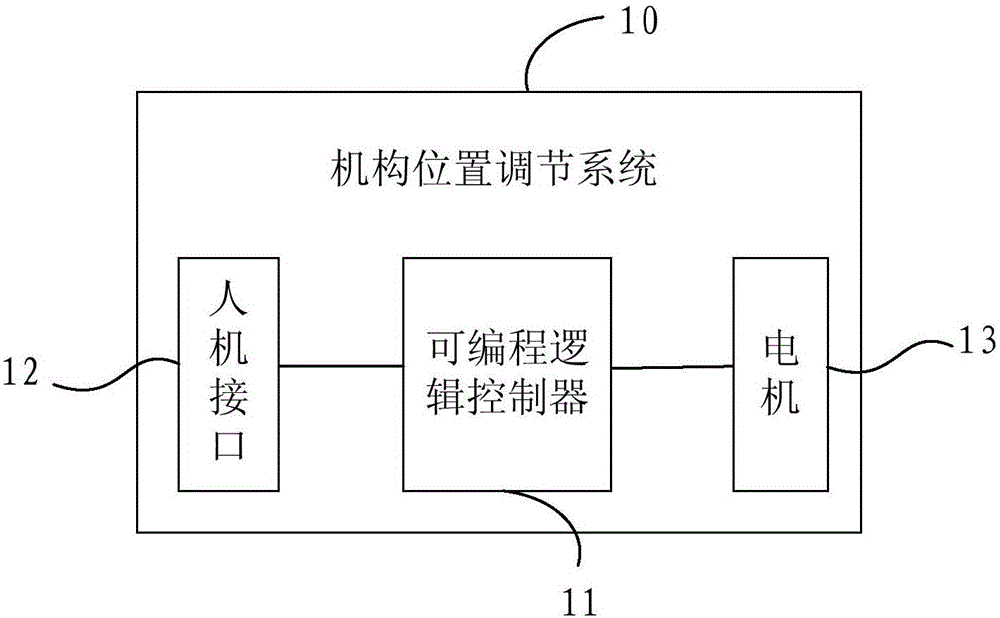

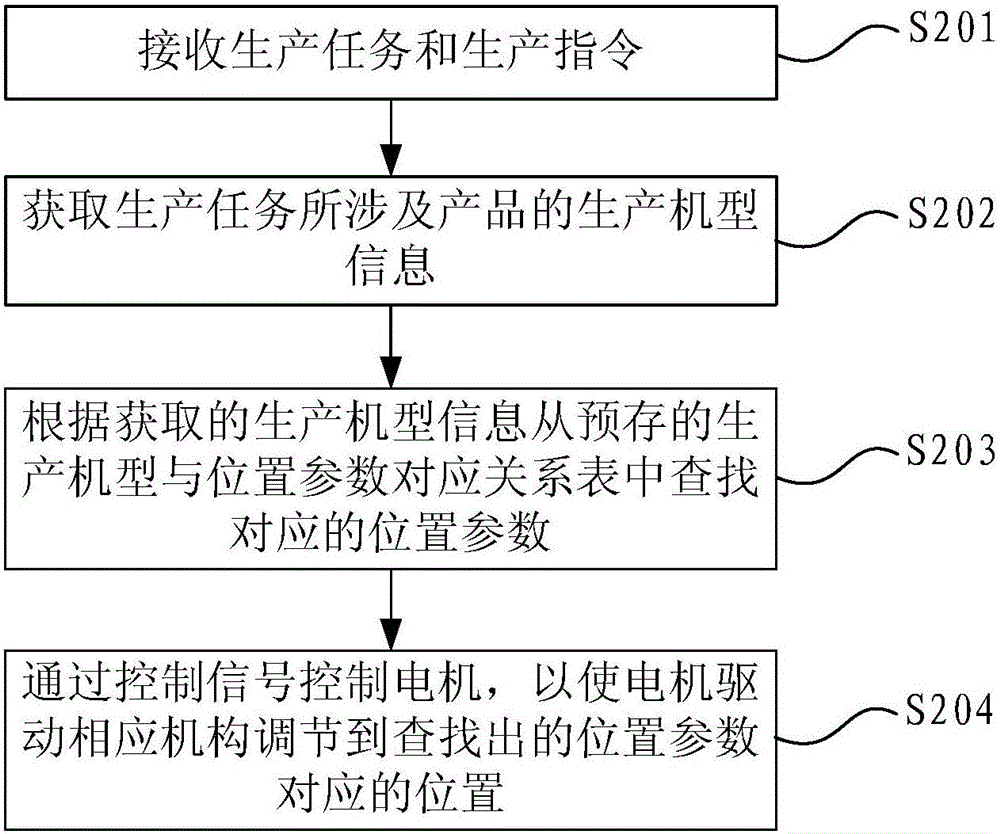

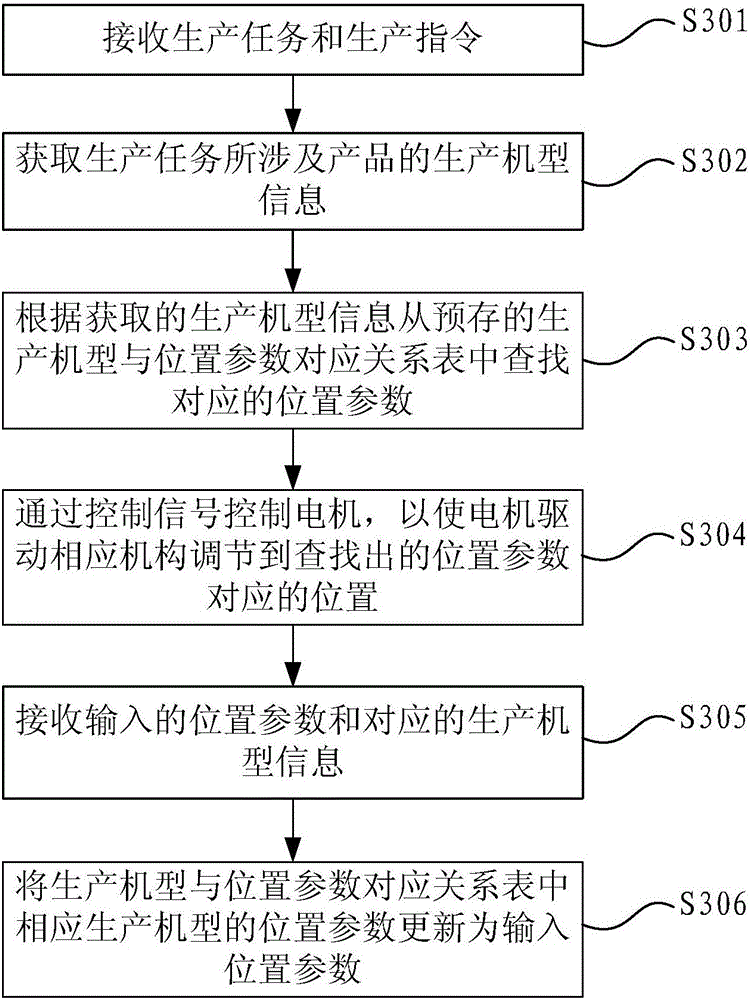

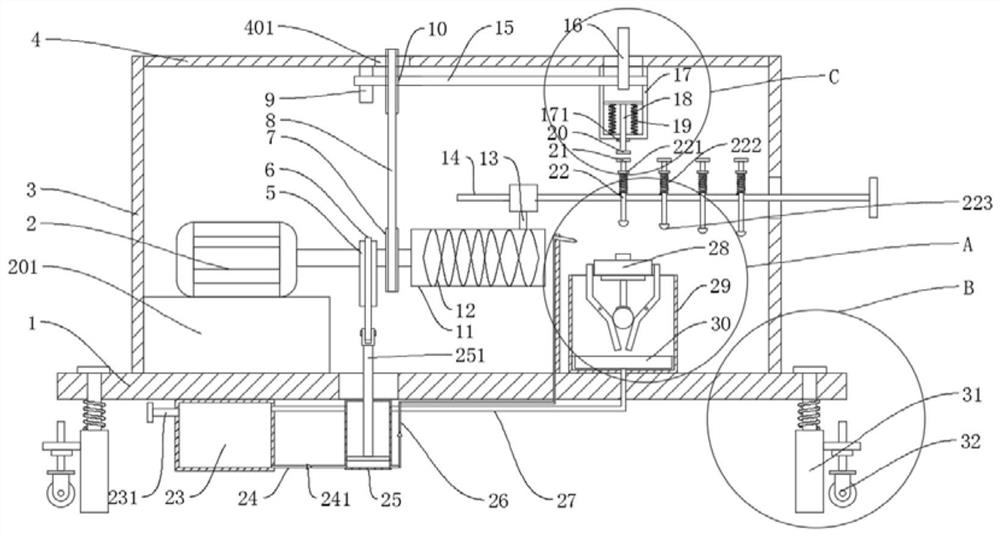

Mechanism position adjusting system and method

InactiveCN106406212AImprove work efficiencyImprove production yieldProgramme control in sequence/logic controllersProgrammable logic controllerManufacturing engineering

The invention relates to a mechanism position adjusting system and method. The mechanism position adjusting system is applied to production equipment and comprises a programmable logic controller PLC, a human-computer interface and at least one motor. The human-computer interface and the motors are connected with the PLC. The motors adjust the positions of corresponding mechanisms on the production equipment under the control of the PLC. The positions of the mechanisms on the production equipment are adjusted by using the motors controlled by electrical signals so that automatic and rapid adjustment of the mechanism positions can be realized, the working efficiency of the production equipment can be enhanced, the production yield rate of the production equipment can also be enhanced and labor cost can be reduced.

Owner:SHENZHEN TINNO WIRELESS TECH

A test tool for pressure sensor and using method thereof

ActiveCN112326115BImprove accuracyImprove utilization efficiencyFluid pressure measurementPermeability/surface area analysisElectric machineryEngineering

Owner:山东中科计量有限公司

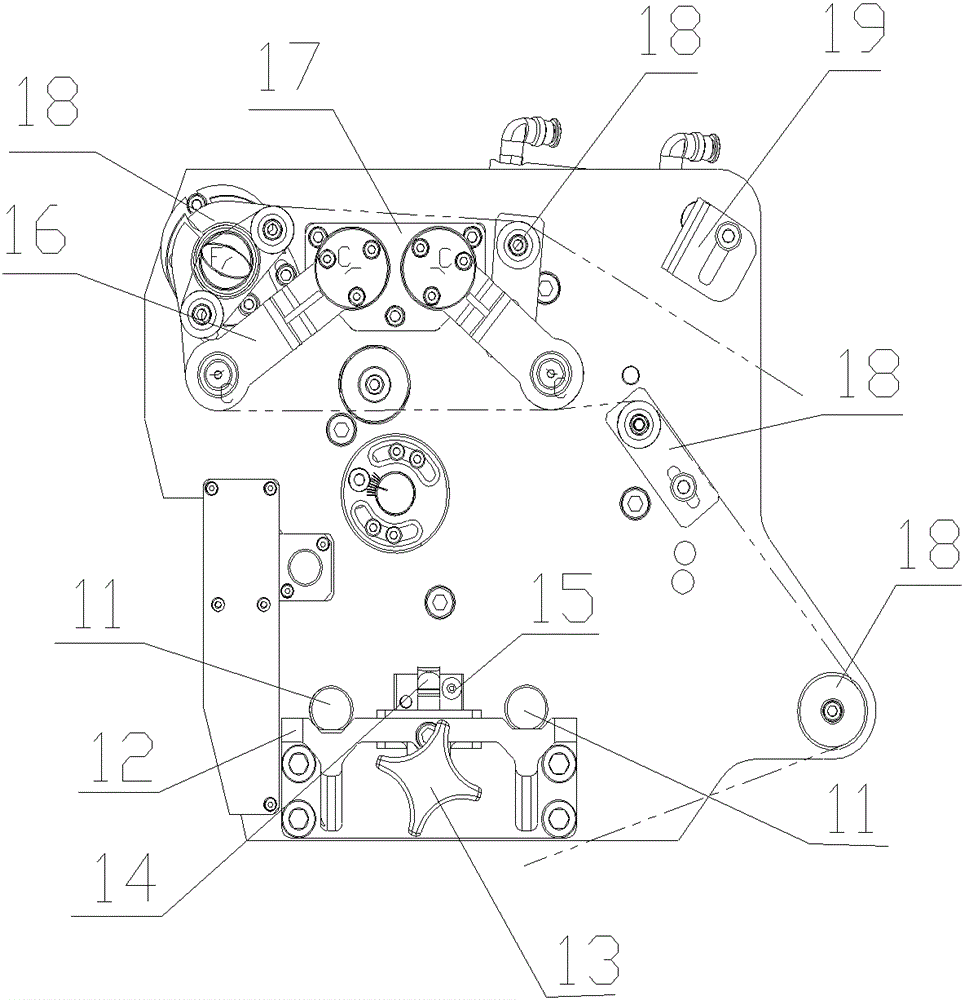

PROTOS unit tipping paper single offset roller gluing system

ActiveCN102871219AUniform thicknessReduce lossCigarette manufacturePaper tapePulp and paper industry

The invention relates to a PROTOS unit tipping paper single offset roller gluing system which comprises a fixing mounting plate and a glue feeding device. A positioning mechanism used for fixing the glue feeding device, a paper raising roller mechanism, a sensor and a positioning pulley used for controlling the trend of tipping paper are arranged on the fixing mounting plate; the glue feeding device is clamped on the positioning mechanism; and the paper raising roller mechanism is arranged above the flue feeding opening of the glue feeding device. Compared with the prior art, the gluing system has the advantages that loss of water in glue solution is reduced, the phenomenon that the glue solution is polluted is avoided, and attrition rate of a glue roller is reduced, so that the service life of the glue roller is greatly increased, the consumption of parts is reduced, and the like.

Owner:上海新平科工业技术有限公司

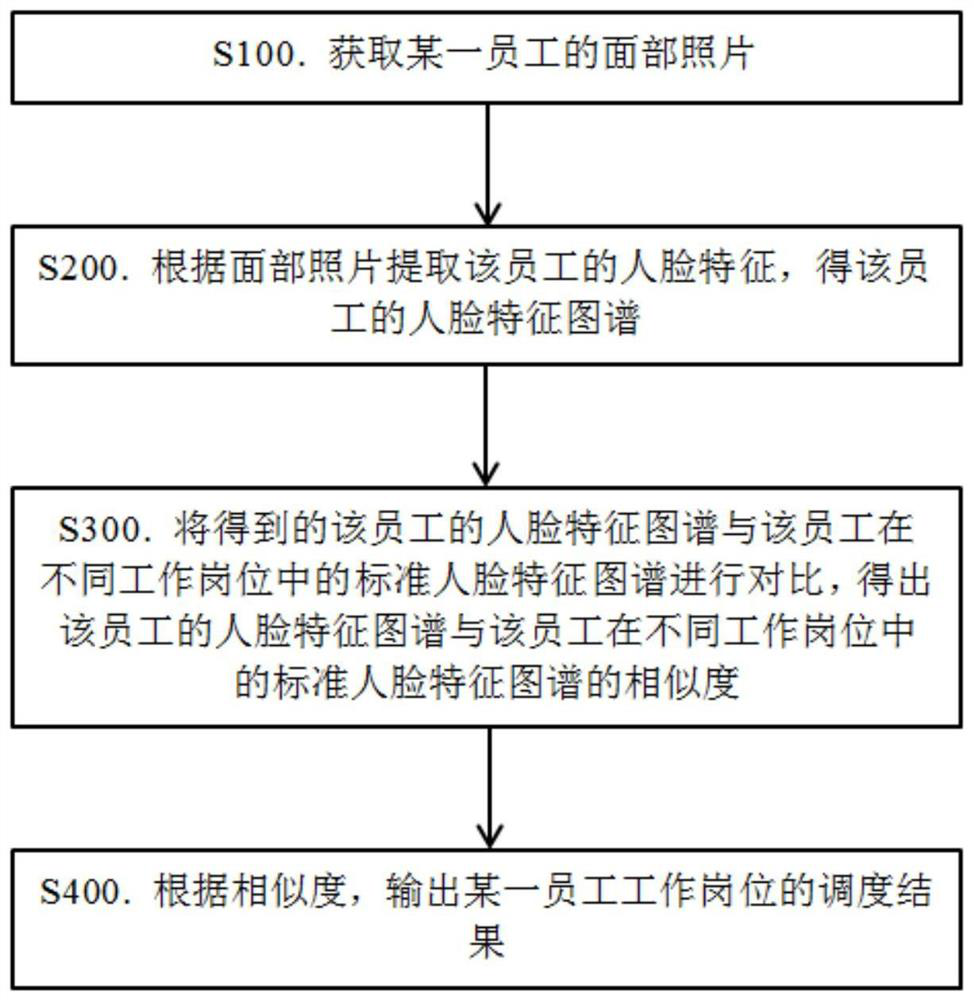

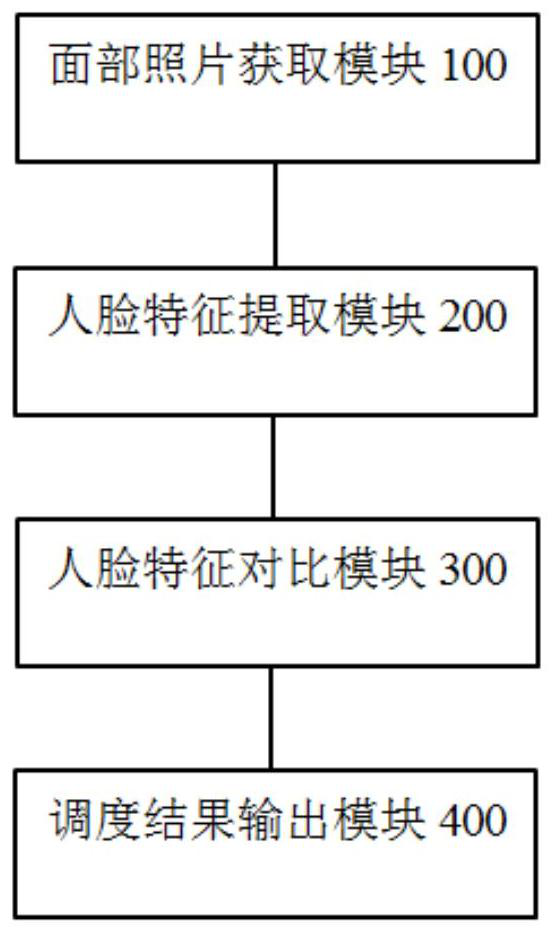

Work scheduling method and system based on employee facial expressions

InactiveCN112070042APromote scientific managementReduce product failureResourcesAcquiring/recognising facial featuresWork schedulingFacial affect

The invention relates to the technical field of industrial software, and particularly discloses a work scheduling method and system based on employee facial expressions. The work scheduling method based on the employee facial expressions comprises the following steps: obtaining a facial picture of a certain employee; extracting face features of the employee according to the facial picture to obtain a face feature spectrum of the employee; comparing the obtained face feature spectrum of the employee with standard face feature spectrums of the employee in different working posts to obtain the similarity between the face feature spectrum of the employee and the standard face feature spectrums of the employee in different working posts; and outputting a scheduling result of the operating postof the certain employee according to the similarity. The method and the system can be used for a factory production line, which working post the employee is suitable can be identified according to theemotions of the employee in different time periods of the day, then the work of the employee is scheduled to the most suitable post, and scientific management is realized.

Owner:广州市森蒲钓具有限公司

Hydrocracking product quality automatic control method, device and storage

ActiveCN111849544BReduce non-conformitiesReduce the problem of low quality modeling dataCharacter and pattern recognitionHydrocarbon oil crackingAutomatic controlProcess engineering

The invention discloses a hydrocracking product quality self-control method, device and memory, wherein the method includes the steps of: acquiring monitoring data of the hydrocracking system; unifying the collection period of various monitoring data according to the preset data standard of the monitoring data and collection time points; determine the parameter items that are related to product quality and can be adjusted in the working condition data as automatic control parameter items; construct modeling data; conduct modeling data based on preset target variables and preset independent variables Model training to generate a product quality prediction model; take the key parameter items determined from real-time monitoring data as input, and obtain the prediction result of the preset product of the hydrocracking system through the product quality prediction model; when the prediction result exceeds the preset range value , according to the prediction model to generate an adjustment scheme for automatic control parameter items. The invention can keep the working condition of the hydrocracking unit in a reasonable running state, and then can effectively reduce the unqualified product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for improving auto-lamp moulds

InactiveCN101987486AAvoid surface damage that requires high surface smoothness treatmentAvoid appearance damageEngineeringService time

The invention discloses a method for improving auto-lamp moulds, which solves the problems of napping, filament flow and deformation of auto-lamp fittings in the process of processing, thereby reducing the rejection ratio of the auto-lamp fittings; and prolonging the service time of the moulds. Through coating a WS2 solid lubricating film on an auto-lamp mould and optimizing the coating thickness, the invention provides a method especially suitable for improving auto-lamp moulds. The method disclosed in invention has the advantages of improving the finished product ratio of auto-lamp fittings subjected to model processing, saving the cost and improving the production efficiency.

Owner:BILL ANDA SHANGHAI LUBRICATING MATERIAL

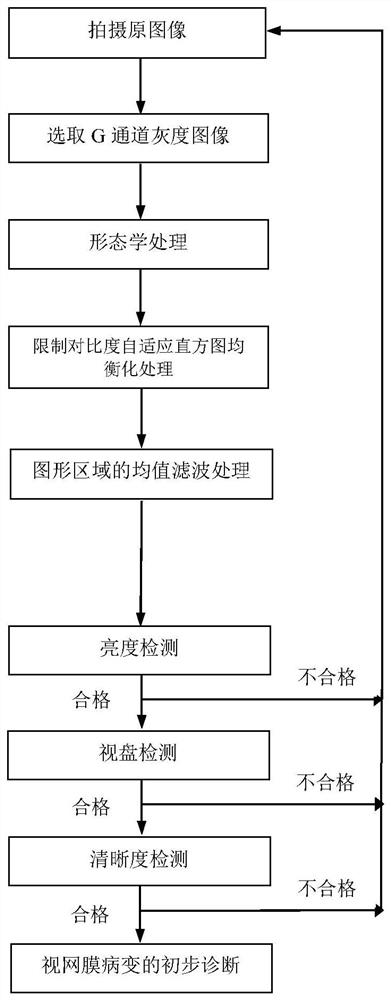

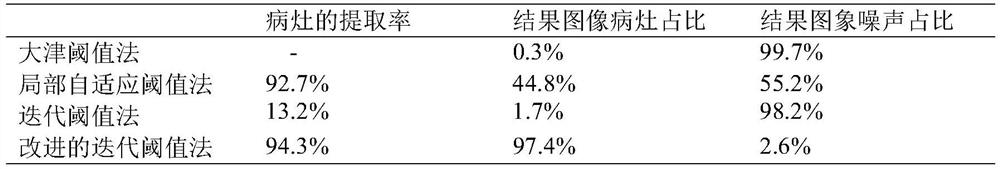

An image quality detection method for diabetic retina based on image analysis technology

ActiveCN109544540BImprove visibilityEasy diagnosisImage enhancementImage analysisImaging qualityImage quality

The present invention relates to the field of image processing technology, and in particular to a method for detecting diabetic retinal image quality based on image analysis technology. The method includes preprocessing of the fundus image. During the preprocessing process, it is subjected to morphological processing, equalization processing and filtering processing. After preprocessing, brightness detection, optic disc detection and sharpness detection are performed to finally obtain the fundus image to be diagnosed. Diagnosis of diabetic retinopathy is made. The preprocessing operation in this method greatly improves the visibility of retinal fundus images, which is more conducive to doctors' diagnosis and analysis of patients' conditions. The quality inspection operation can greatly reduce the failure of fundus images taken at census points. occurrence, fundus images that pass the quality inspection method can be used to make a preliminary diagnosis of diabetic retinopathy.

Owner:NORTHEASTERN UNIV LIAONING

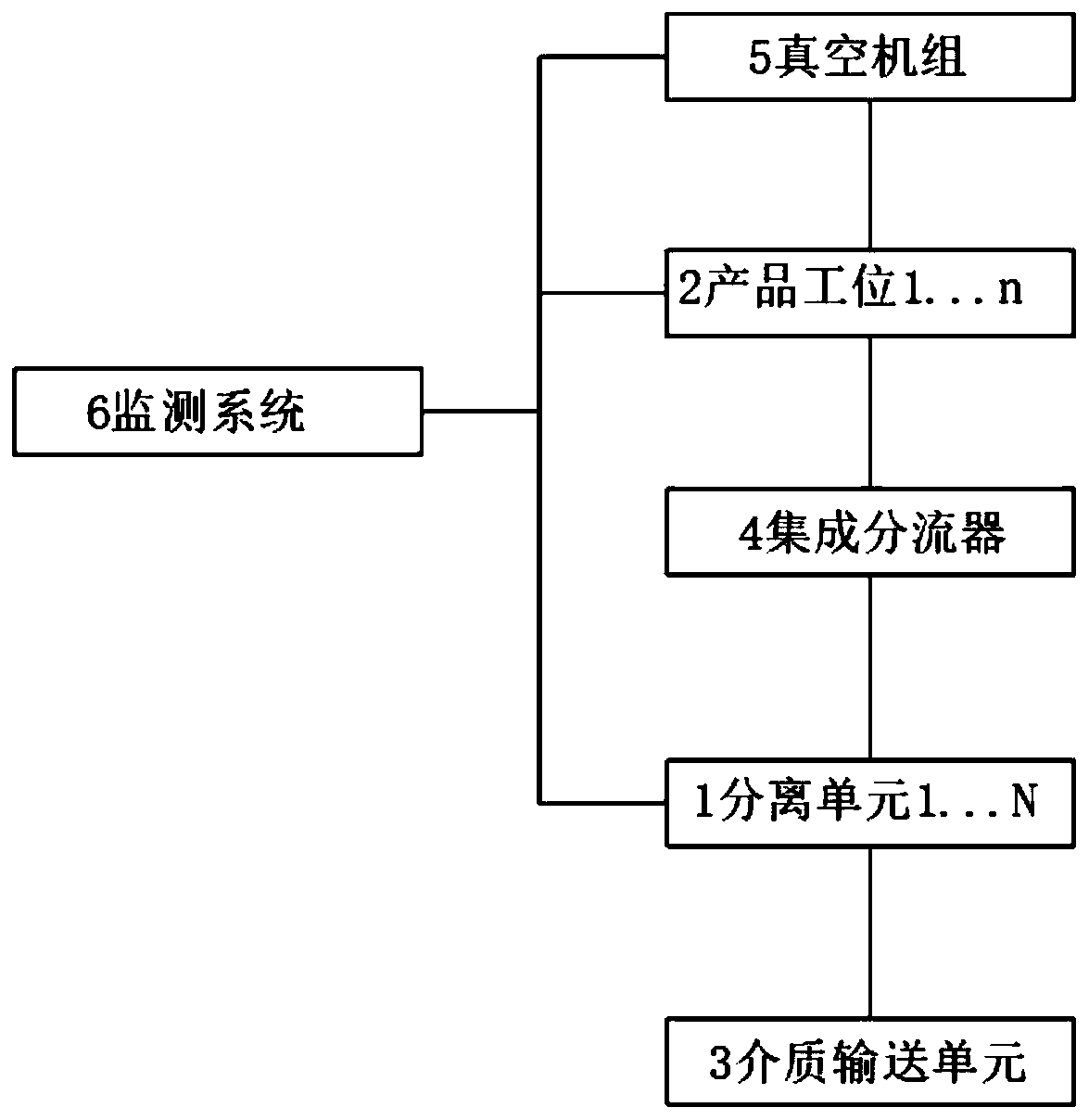

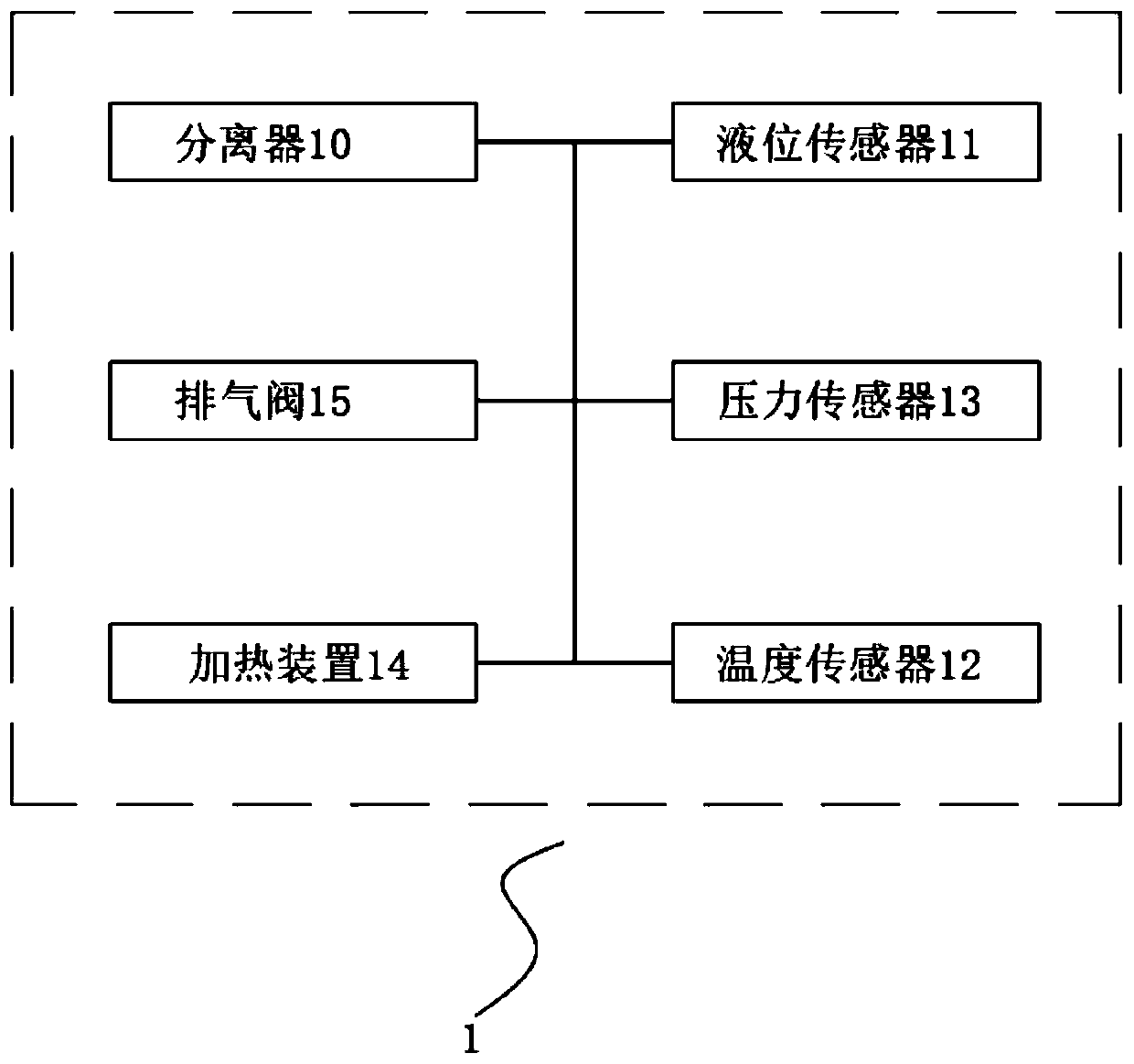

High-vacuum multi-station liquid adding system

PendingCN111538304AImprove work efficiencyReduce product failureDomestic cooling apparatusRefrigeration componentsAutomatic controlProcess engineering

The invention provides a high-vacuum multi-station liquid adding system, and relates to the field of liquid adding systems. The high-vacuum multi-station liquid adding system comprises a separation units, product stations, a medium conveying unit, an integrated flow divider, a vacuum unit and a monitoring system, wherein the medium conveying unit is communicated with the separation units through liquid inlet pipes, the separation units are communicated with the integrated diverter through liquid outlet pipes, the integrated diverter is communicated with the product stations through pipelines,the vacuum unit is communicated with the product stations through pipelines, and the number of the product stations and the number of the separation units are both multiple. The liquid adding system is reasonably designed, so the system realizes integrated automatic control, realizes controllable functions of automatically judging whether vacuum reaches the standard or not, accurately and quantitatively filling, separating, purifying, degassing and drying, can realize flexible use of multiple functions of automatic turn-off, opening, sealing, high-vacuum liquid filling and the like, is safe, reliable, convenient and quick, and greatly improves the operation efficiency.

Owner:浙江赛西自动化科技有限公司

Railway traction type railway ballast separating and shaping device

The invention relates to the technical field of railway maintenance, and discloses a railway traction type railway ballast separating and shaping device which comprises a base, the right side of the lower surface of the base is fixedly connected with a connecting plate, the left side of the lower surface of the base is detachably connected with another connecting plate, and a plurality of sliding mechanisms are installed on the opposite sides of the two connecting plates. Supporting plates are fixedly connected to the front portion and the rear portion of the left side of the base correspondingly, a transverse plate is jointly placed on the upper surfaces of the two supporting plates, and the transverse plate is fixedly connected with the connecting plate through a long strip. When the designed device is used, a first gear drives a metal chain belt to rotate, a sliding block can rotate while moving along with the metal chain belt, the sliding block is embedded in a concentric-square-shaped plate, a fixed block in front of the concentric-square-shaped plate is embedded in a sliding groove, and the concentric-square-shaped plate can move leftwards and then move rightwards in the sliding block moving process; and the railway ballast at the high bulge position beside the rail can be conveniently pushed to one side position.

Owner:中国铁路西安局集团有限公司安康工务段

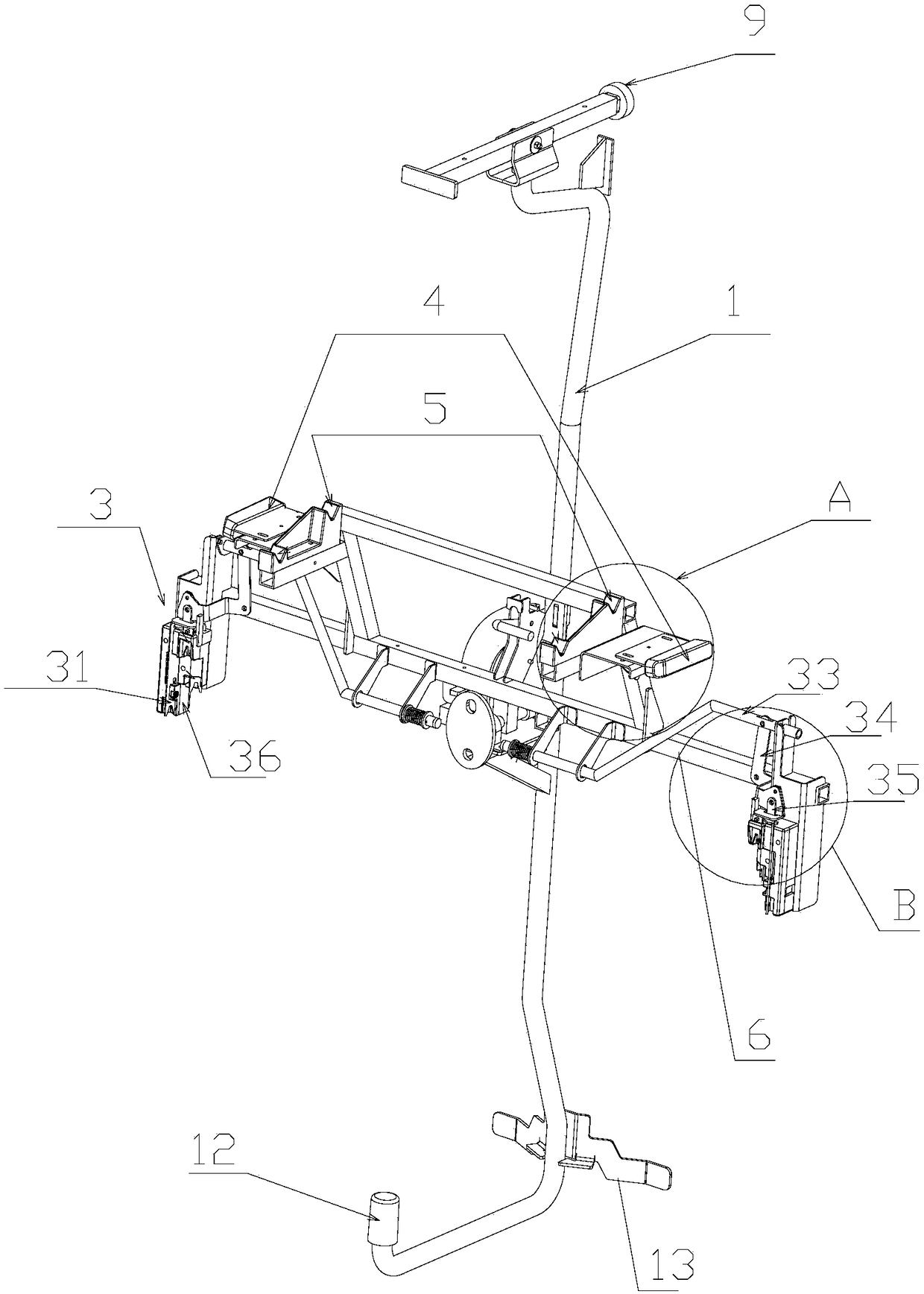

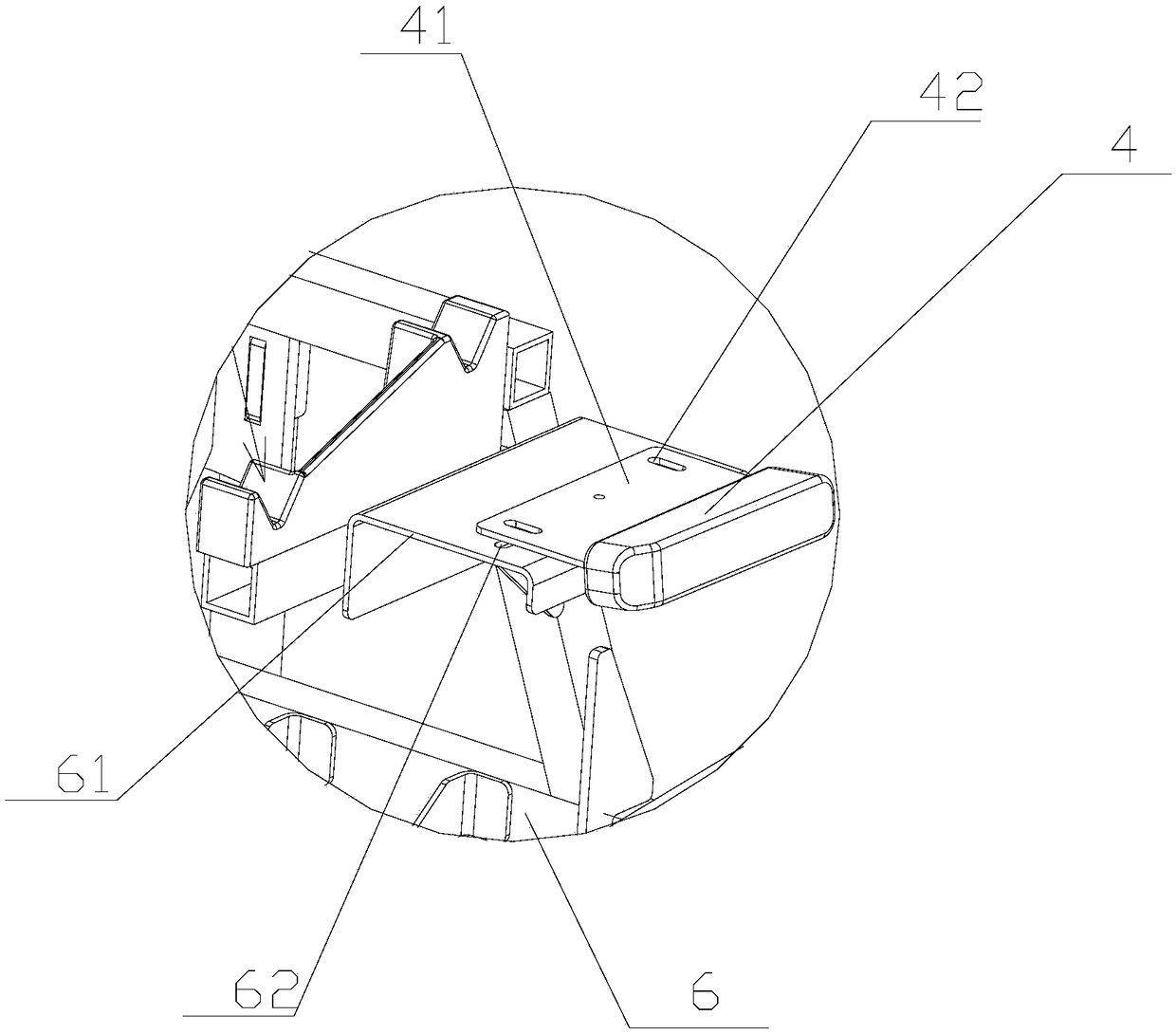

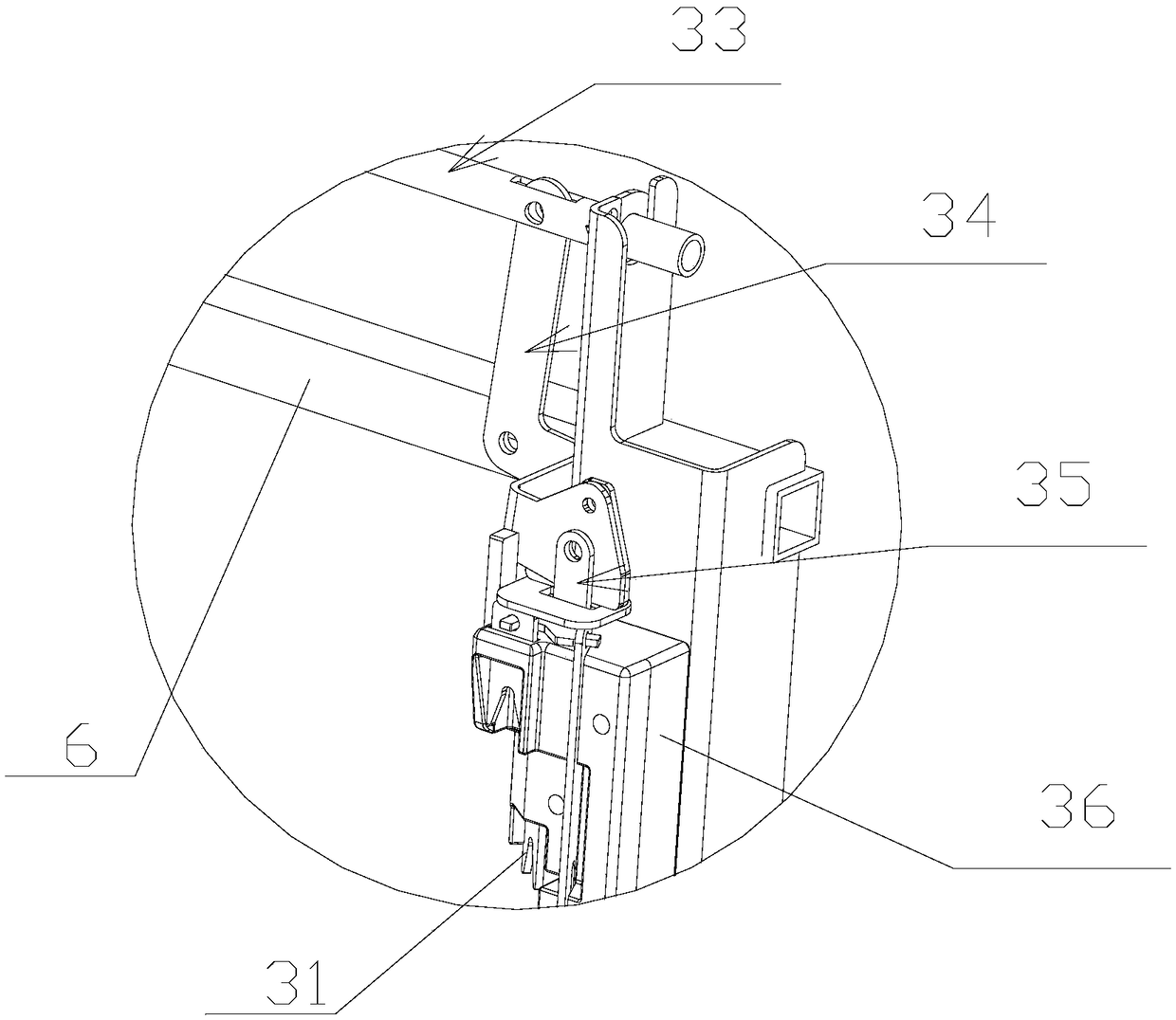

A tailgate catenary transport device

The invention relates to a tail door suspension chain transport device which comprises a supporting rod and a tail door fixing device. The tail door fixing device is mounted on the supporting rod. Thesupporting rod is located in the middle of the tail door fixing device. A pulley is arranged at the top of the supporting rod. The tail door fixing device comprises locking devices, fixed clamp grooves, a limiting device used for limiting left-and-right movement of a tail door and a support, and the locking devices, the limiting device and the fixed clamp grooves are all mounted on the support. The limiting device comprises limiting blocks. Each locking device comprises at least one tongue piece and an adjusting mechanism used for adjusting the up-and-down position of the tongue piece. A ballhead pin clamp groove is formed in each tongue piece. The tail door fixing device is mounted on the supporting rod through a bearing and a limiting pin. According to the tail door suspension chain transport device, the transport efficiency can be improved, and the transport cost can be reduced; and flexible transport is achieved, and the situation that products are unqualified due to the reasonssuch as colliding generated in the transport process is reduced.

Owner:东风彼欧(成都)汽车外饰系统有限公司

16-18mm plate thickness aluminum and aluminum alloy tungsten inert gas (TIG) welding process

InactiveCN104475937AStable the whole processQuality improvementArc welding apparatusWelding/cutting media/materialsShielding gasAlloy

The invention discloses a 16-18mm plate thickness aluminum and aluminum alloy tungsten inert gas (TIG) welding process. The welding process is characterized by including the following steps that an X-shaped groove is selected according to the plate thickness and a welding position, the front side included angle is 60 degrees, the reverse side included angle is 45 degrees, the truncated edge is 2-3mm, and the root gap is 0-3mm; greasy dirt, aluminum skimmings and oxidation films of to-be-welded positions in a range of 50mm of aluminum alloy plate end faces and edges are cleaned by acetone before welding so as to expose metallic luster; TIG welding is applied, and welding process parameters are set, for example, the welding current is 360-380A, the protective gas flow is 24-25L / min, the tungsten electrode diameter is 6mm, the welding wire diameter is 5-6mm, and nozzle hole diameter is 16-20mm; welded positions are preheated, the preheating temperature is 200-220 DEG C, and the preheating time is 0.5-1min; during welding, two operators synchronously perform manual TIG vertical position welding from bottom to top on outer surfaces and inner surfaces of workpieces respectively, a welding gun of the outer surfaces of the workpieces serves as a main gun to perform orderly welding gun left-right swinging and wire filling, and a welding gun of the inner surfaces of the workpieces assists in wire filling. By means of the 16-18mm plate thickness aluminum and aluminum alloy TIG welding process, the welding process can be performer under effectively control, stable whole process and products qualities can be guaranteed, and phenomena of unqualified products are reduced.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

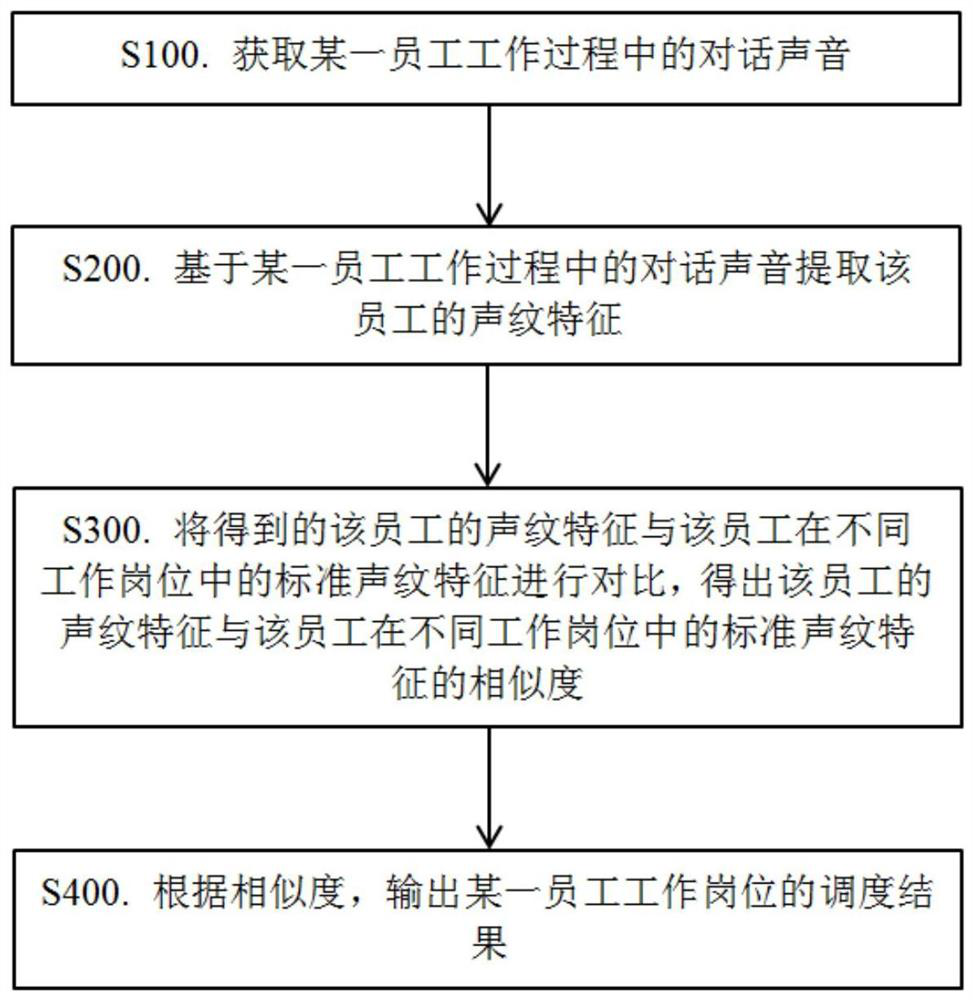

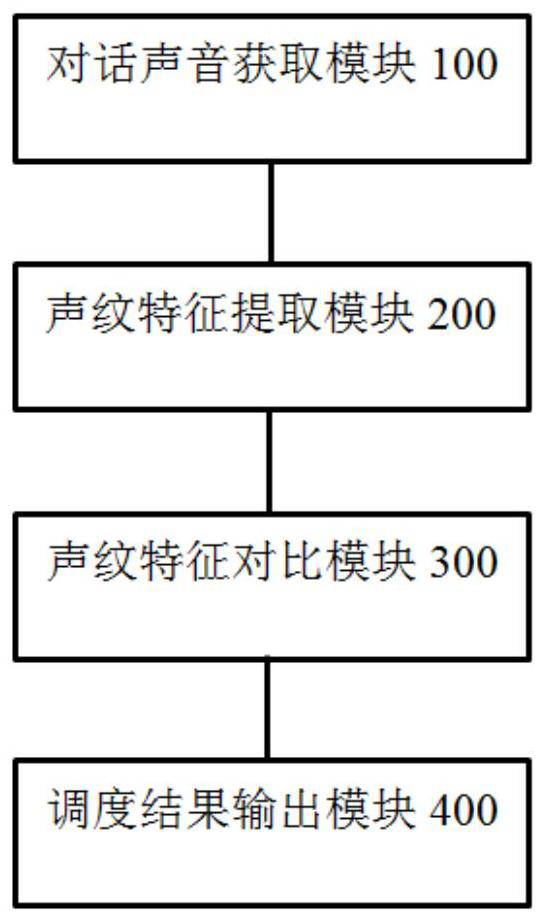

Job scheduling method and system based on conversation voice of employee

InactiveCN112071321AIncrease productivityEasy to manage scientificallySpeech analysisResourcesProduction lineIndustrial software

The invention relates to the technical field of industrial software, and particularly discloses a job scheduling method based on conversation voice of an employee. The job scheduling method comprisesthe following steps of obtaining the conversation voice of one employee in the working process; extracting the voiceprint features of the employee based on the conversation voice of the employee in the working process; comparing the voiceprint features of the employee with the standard voiceprint features of the employee in different operating posts to obtain the similarity of the voiceprint features of the employee with the standard voiceprint features of the employee in different operating posts; and according to the similarity, outputting the scheduling result of the operating post of the employee. The method and the system can be used for a factory production line; according to the emotions of the employee during different time periods on the same day, the system can identify that theemployee is suitable for which one of the operating posts; further, the job of the employee is scheduled to let the employee work in the most suitable post; and scientific management is achieved.

Owner:广州市森蒲钓具有限公司

Aluminum and aluminum alloy inert-gas shielded welding process suitable for plates of 8-12 mm thickness

InactiveCN104526120AQuality improvementReduce non-conformitiesArc welding apparatusWelding/cutting media/materialsTectorial membraneFlame cutting

The invention discloses an aluminum and aluminum alloy inert-gas shielded welding process suitable for plates of 8-12 mm thickness. The aluminum and aluminum alloy inert-gas shielded welding process comprises the steps of adopting flame cutting to cut a welding product so as to obtain 40-degree double-faced one-sided groove with welding joint ratio of 1:2 and ensuring that no grooves exist in the cutting face; sticking a protective film to the plate product, adopting acetone and a rotary file to remove oil stains, aluminum chippings and oxidation films at the positions to be welded, on the end face and edge of the aluminum alloy plate within 20 mm range and expose metal luster before welding, wherein no air bubbles exist in the protective film, the protective film is not bonded in a 50-100 mm range within the welding position; adopting inert-gas shielded welding; selecting corresponding aluminum alloy welding wires to perform welding according to material models of aluminum and aluminum alloy plates during welding, and continuing to perform welding without stop in the middle process. By means of the aluminum and aluminum alloy inert-gas shielded welding process, the process of the welding process can be effectively controlled, the whole process and product quality stability are ensured, disqualification phenomena are decreased, and the aluminum and aluminum alloy inert-gas shielded welding process is suitable for aluminum and aluminum alloy welding of the plates of 8-12 mm thickness.

Owner:WUHU CIMC RUIJIANG AUTOMOBILE

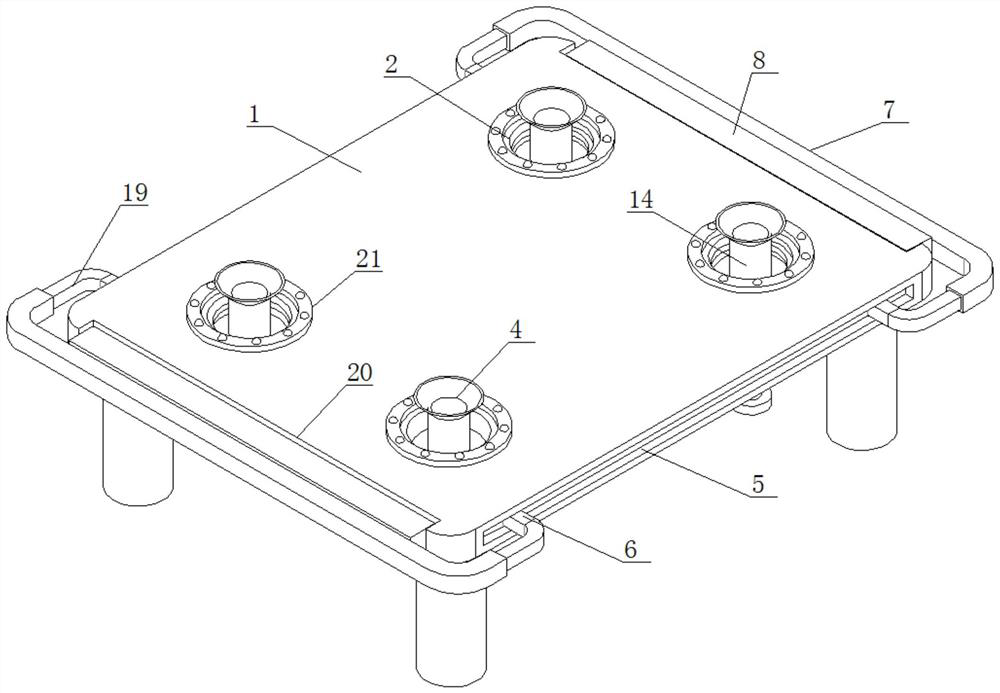

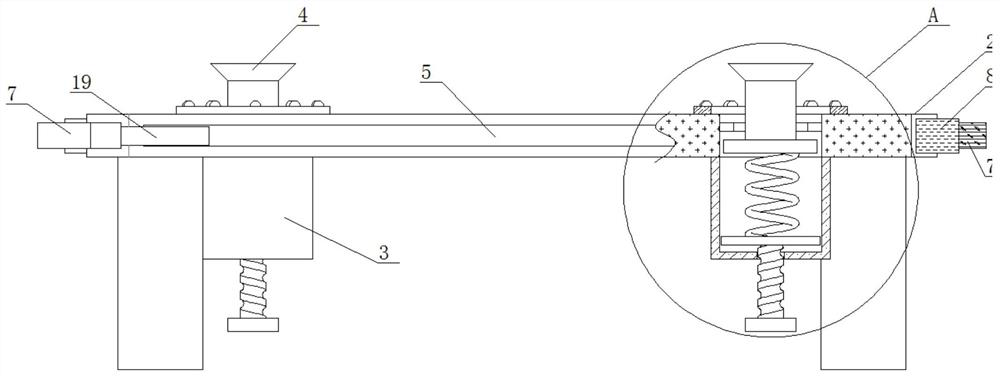

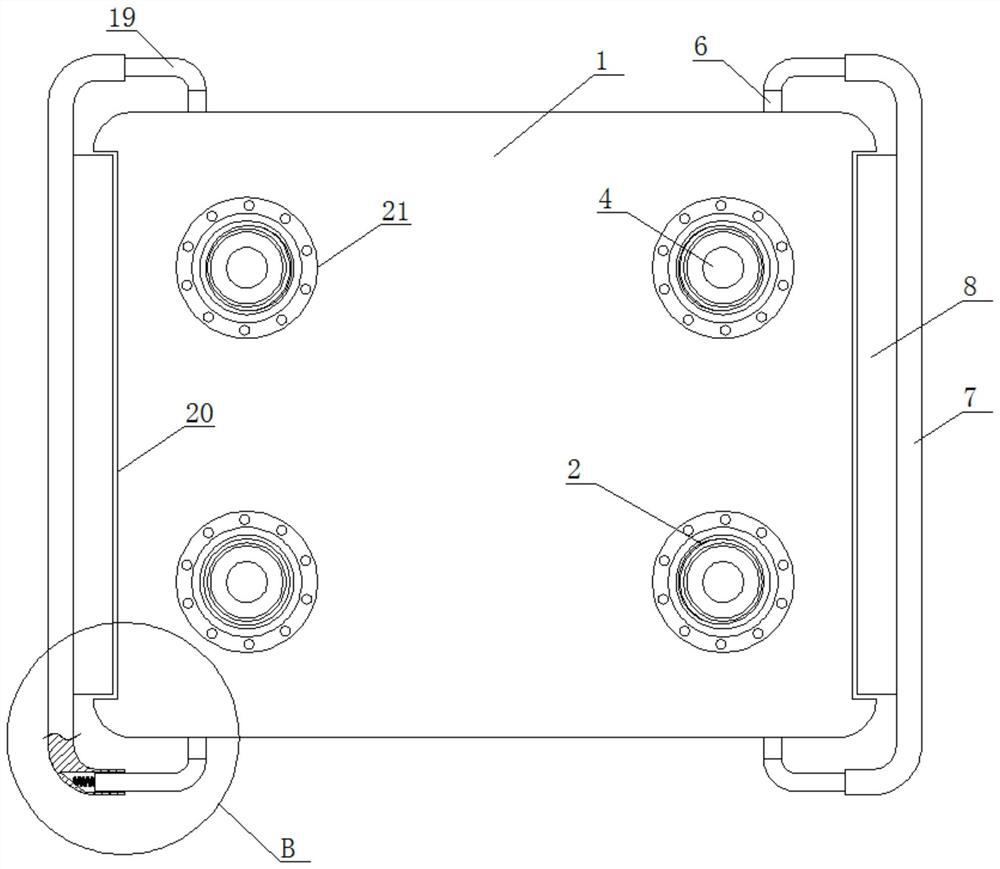

Glass processing fixing device

PendingCN113997441AWide range of applicationsReduce glass failureWorking accessoriesGrinding work supportsStructural engineeringMechanical engineering

The invention discloses a glass processing fixing device, and relates to the technical field of glass processing. The device comprises a bottom plate, the upper surface of the bottom plate is provided with four symmetrical round holes, the bottom surface of the bottom plate is fixedly connected with four symmetrical buffer mechanisms, the top end of each buffer mechanism communicates with one round hole, the top end of each buffer mechanism is fixedly connected to a suction cup, sliding grooves are formed in the front face and the back face of the bottom plate, the inner wall of each sliding groove is slidably connected to a set of sliding blocks, limiting mechanisms are arranged on the left side face and the right side face of the bottom plate, and the two ends of each limiting mechanism are hinged to the two sliding blocks. The device is reasonable in design structure, the application range of the device can be wider by arranging the buffer mechanisms and adjusting the buffering capacity of the buffer mechanisms, and by arranging the limiting mechanisms, the glass can be fixed more firmly by stretching a U-shaped rod and clamping the upper surface of the glass.

Owner:浙江蓝欣玻璃科技股份有限公司

Pressure sensor testing tool and using method thereof

ActiveCN112326115AImprove accuracyImprove utilization efficiencyFluid pressure measurementPermeability/surface area analysisElectric machineryCam

The invention discloses a pressure sensor testing tool and a using method thereof, and belongs to the field of pressure sensors. The pressure sensor testing tool comprises a base, wherein a fixing block, a supporting plate, a fixing frame and a die holder are fixedly connected to the base, a motor is fixedly connected to the fixing block, a top plate is fixedly connected to the supporting plate, arotating rod is rotatably connected into the top plate, the motor is rotatably connected with the rotating rod through a transmission mechanism, a sliding frame is fixedly connected to the top plate,and a cam is rotatably connected into the sliding frame. The pressure sensor testing tool is simple to use and diversified in detection function, the data accuracy of a pressure sensor is effectivelyimproved and the reliability of the pressure sensor is improved by performing pressing detection of different pressures on the pressure sensor, and meanwhile, the waterproofness of the pressure sensor can be detected by performing circulating water spraying on the pressure sensor, and the applicability of the pressure sensor in different environments is improved.

Owner:山东中科计量有限公司

Protos unit tipping paper single rubber roller gluing system

The invention relates to a PROTOS unit tipping paper single offset roller gluing system which comprises a fixing mounting plate and a glue feeding device. A positioning mechanism used for fixing the glue feeding device, a paper raising roller mechanism, a sensor and a positioning pulley used for controlling the trend of tipping paper are arranged on the fixing mounting plate; the glue feeding device is clamped on the positioning mechanism; and the paper raising roller mechanism is arranged above the flue feeding opening of the glue feeding device. Compared with the prior art, the gluing system has the advantages that loss of water in glue solution is reduced, the phenomenon that the glue solution is polluted is avoided, and attrition rate of a glue roller is reduced, so that the service life of the glue roller is greatly increased, the consumption of parts is reduced, and the like.

Owner:上海新平科工业技术有限公司

IC card packaging device and method

ActiveCN104733358BKeep it flatImprove aestheticsSemiconductor/solid-state device manufacturingThermal HeadElectrical and Electronics engineering

The invention provides an IC card packaging device and method. The IC card packaging device includes a packaging platform, a hot pressing device, a cold pressing device, a negative pressure device, a transmission device and a power unit, and the hot pressing device and the cold pressing device are along the IC The card transmission direction is set in sequence, the hot pressing device includes a hot pressing head, and a heating device is arranged in the hot pressing head; the cold pressing device includes a cold pressing head, and a card slot matching the size of the IC card is provided on the packaging platform , the bottom surface of the card slot is provided with adsorption pores, and the negative pressure device communicates with the adsorption pores. When the cold pressure head cold-presses the IC card in the card slot, the adsorption pores absorb the plastic card base in the card slot with negative pressure, so that the lower surface of the plastic card base in the softened state becomes regular and flat, which greatly improves the The aesthetics of the card surface.

Owner:HONGBO CO LTD

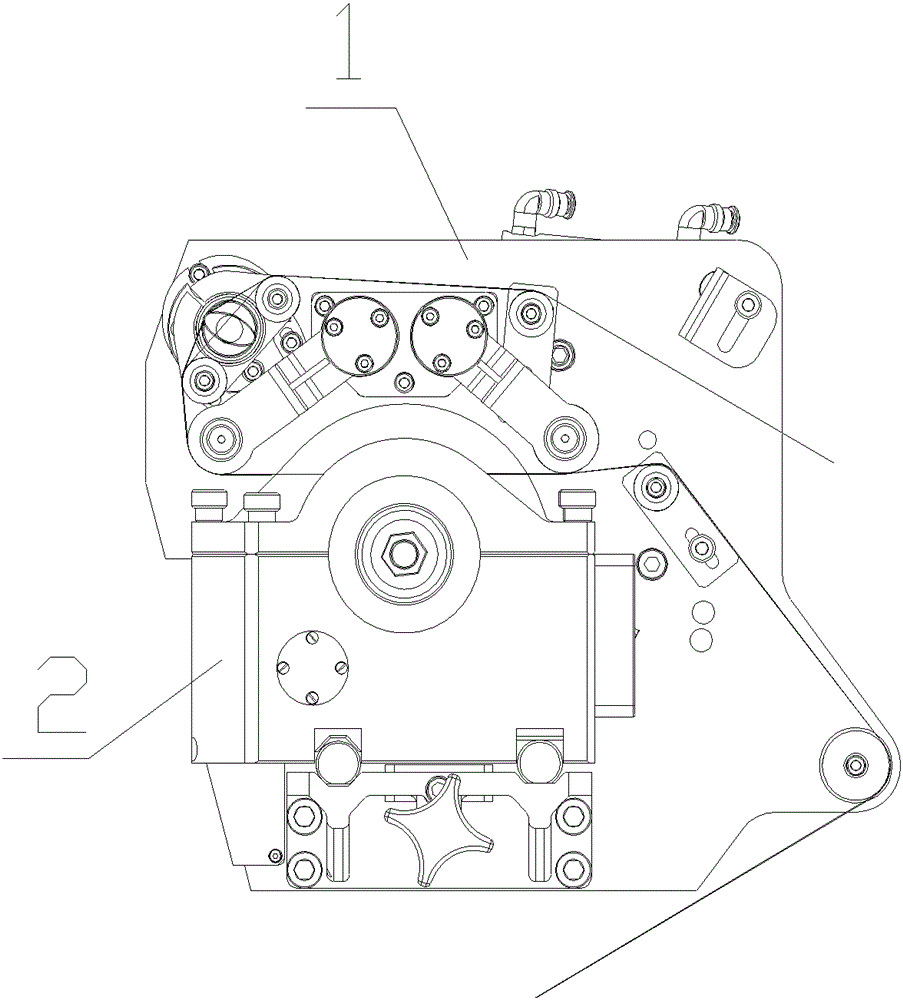

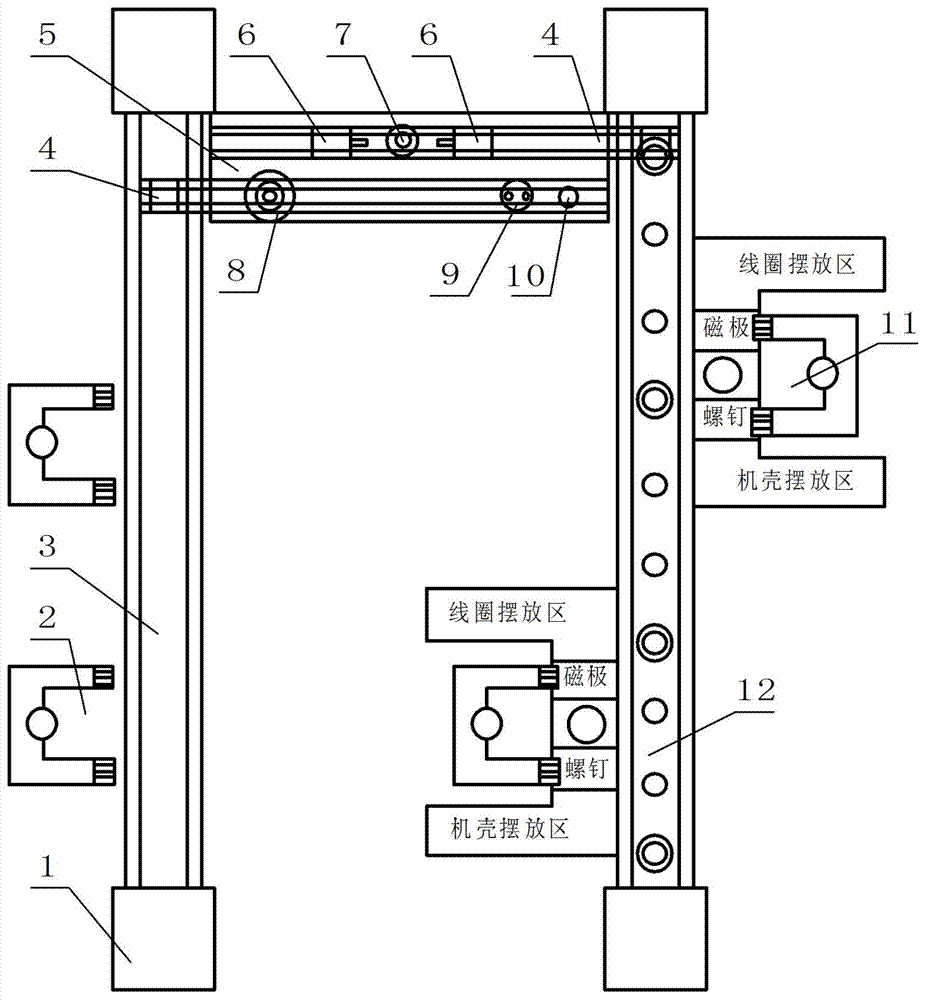

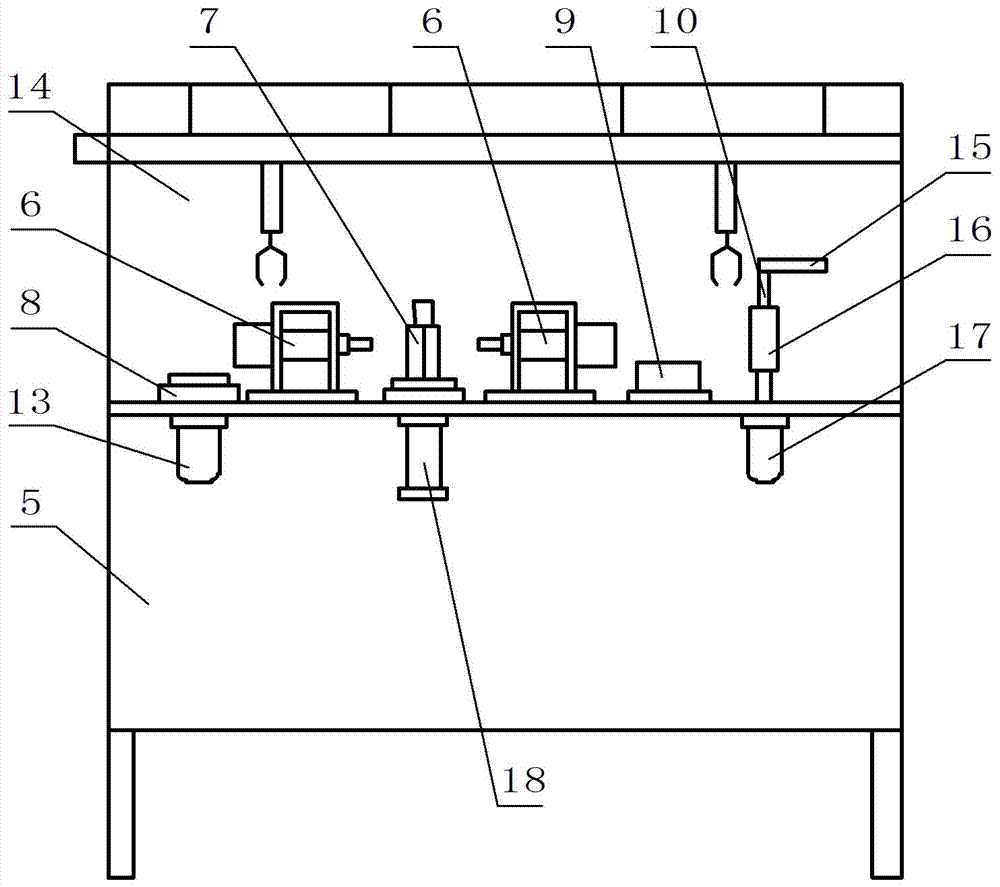

Starter stator automatic assembly line

ActiveCN105397483BReduce labor intensityImprove work efficiencyAssembly machinesMetal working apparatusProduction lineAssembly line

The invention discloses an automatic assembly line for a starter stator. The automatic assembly line comprises a feeding conveying device, a full-automatic tensioner and a discharging conveying device, wherein the full-automatic tensioner is composed of a worktable and a box body; the worktable is arranged at the upper end of the box body; a glass frame cover is arranged on the worktable; two grasping and moving devices are arranged at the upper part of the glass frame cover; a stator fixing table, a withstand voltage detection table and a size detection table are arranged on the worktable respectively; two bolt screwing devices are symmetrically arranged on the two sides of the stator fixing table; and a voltage applying device is arranged on one side of the withstand voltage detection table. The automatic assembly line integrates bolt screwing, withstand voltage detection and size detection, and thus greatly weakening the labor intensity of workers, improving the working efficiency and meanwhile, reducing man-made unqualified factors.

Owner:XINXIANG HUIHUANG SPRING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com