Starter stator automatic assembly line

An assembly line and machine stator technology, applied in the field of starter stator automatic assembly line, can solve the problems of products losing market competition advantages, product appearance bump damage, increase in manufacturing costs, etc., to achieve easy promotion and implementation, reduce unqualified factors, and work efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

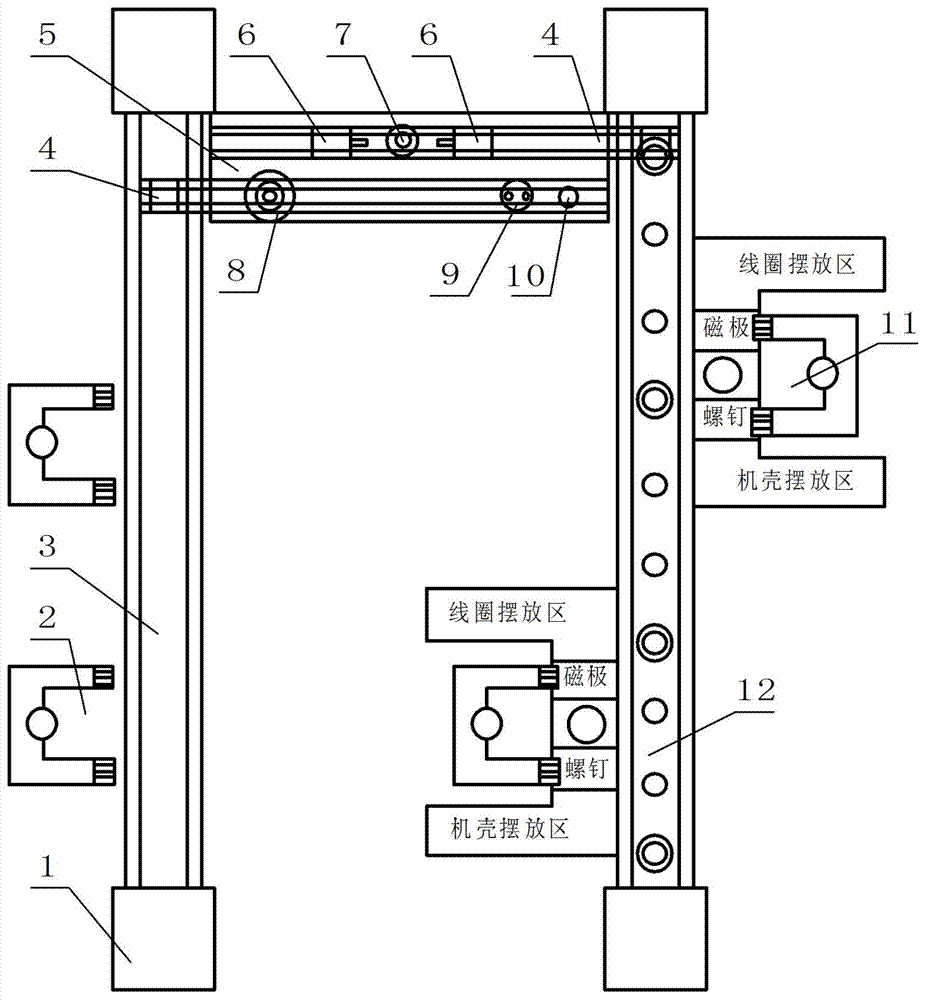

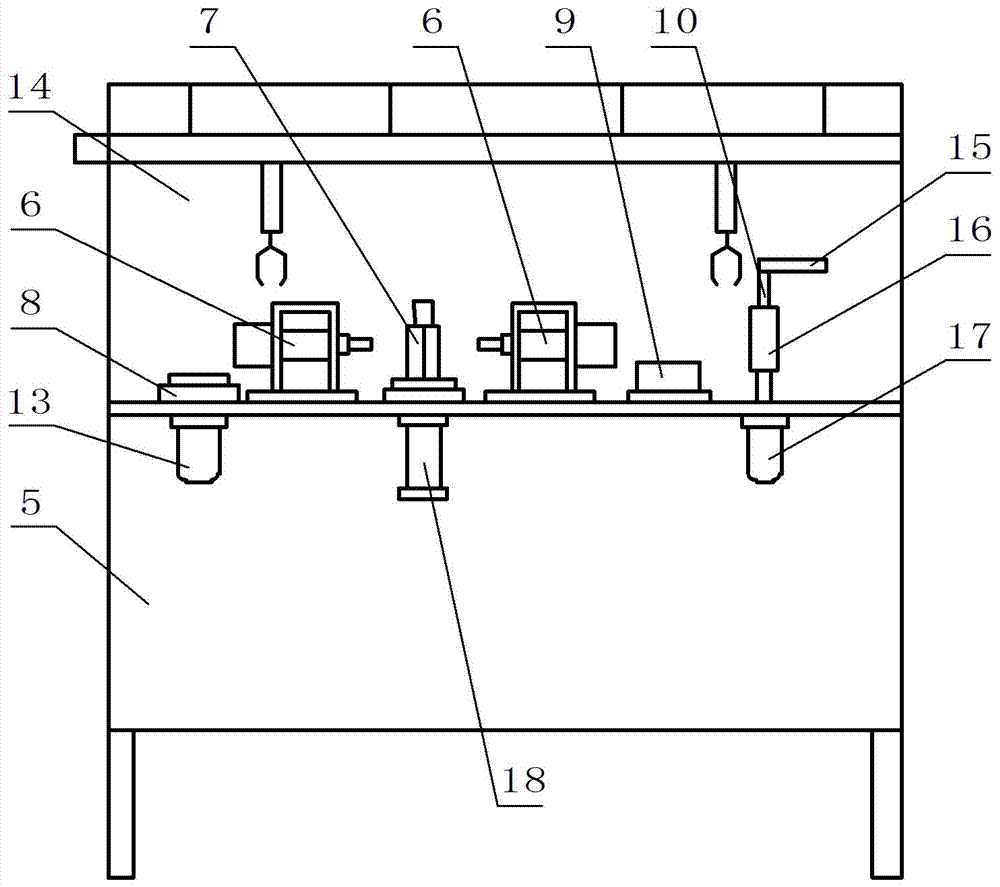

[0022] Example: see figure 1 and figure 2 , in the figure, 1-bracket, 2-packing station, 3-discharging and transporting device, 4-grabbing and moving device, 5-automatic tensioning machine, 6-bolt tightening device, 7-stator fixing table, 8 -Dimension testing platform, 9-Pressure testing platform, 10-Voltage application device, 11-Material loading station, 12-Feeding and transportation device, 13-Size testing drive motor, 14-Glass frame cover, 15-Voltage plate, 16-telescopic pressure cylinder, 17-voltage drive motor, 18-tension pressure cylinder.

[0023] The starter stator automatic assembly line includes a feeding transport device 12, a fully automatic tensioner 5 and a discharge transport device 3, wherein: the fully automatic tensioner 5 includes a working table and a box, and the working table is set on the upper end of the box. A glass shelf cover 14 is arranged on the worktable, and two grasping and moving devices 4 are arranged on the upper part of the glass shelf c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com