Production device and production process of organosilane crosslinked polyethylene insulated overhead insulation cable in one step

An overhead insulated cable, polyethylene insulation technology, applied in the direction of conductor/cable insulation, etc., can solve the problems of increased transportation and production costs, raw materials cannot be stored for a long time, and raw materials cannot be used normally, so as to reduce the long parking time and production The effect of cost reduction and reduction of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

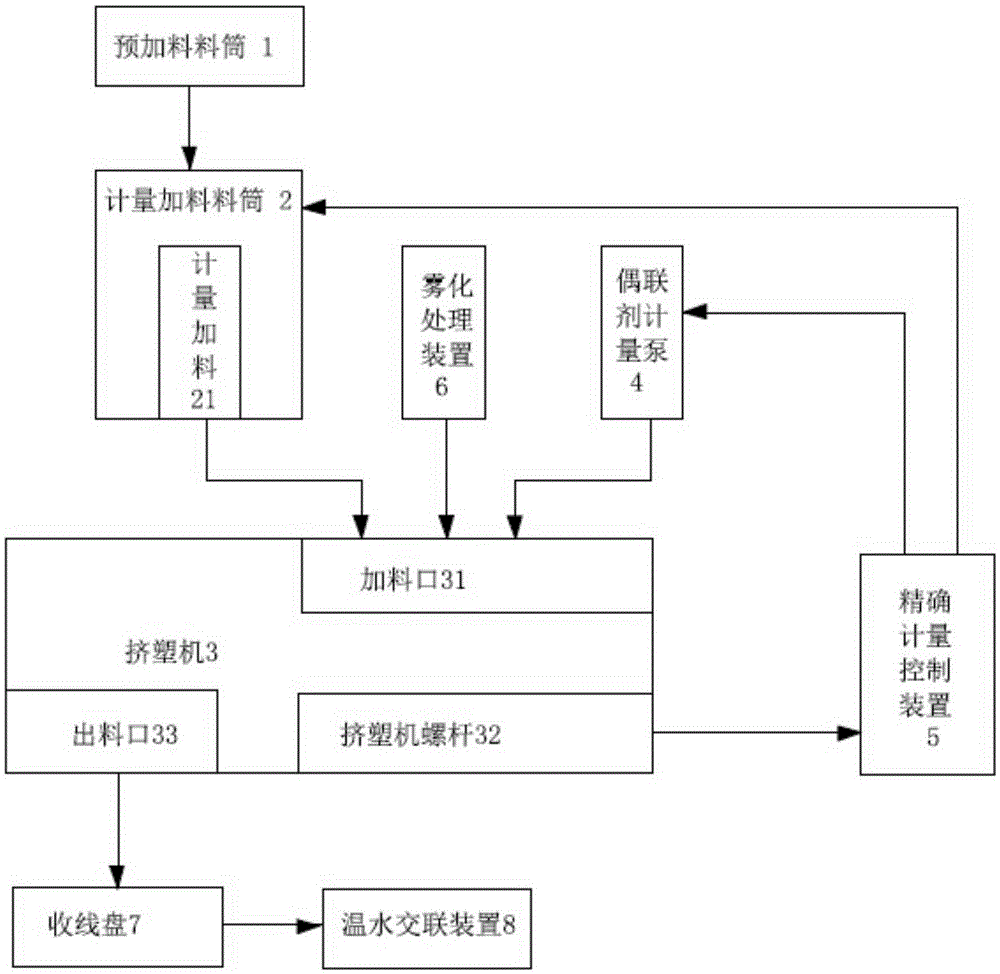

[0024] See figure 1 , the one-step silane crosslinked polyethylene overhead insulated cable production equipment of this embodiment includes a pre-feeding barrel 1, a metering and feeding barrel 2, an extruder 3, a coupling agent metering pump 4, an accurate metering control device 5, and a mist Chemical treatment device 6, take-up reel 7 and warm water cross-linking device 8. The outlet of the pre-feeding barrel 1 is connected to the inlet of the metering feeding barrel 2; the metering screw 21 is arranged at the outlet of the metering feeding barrel 2, and the outlet of the metering feeding barrel 2 is connected to the feeding port 31 of the extruder 3; the coupling agent is metered The outlet of the pump 4 communicates with the feeding port 31 of the extruder 3; the precise metering control device 5 obtains the parameters of the extruder screw 32 of the extruder 3 and feedbacks the output and coupling of the metering screw 21 of the metering feeding barrel 2 The output of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com