Pressure sensor testing tool and using method thereof

A technology of pressure sensor and test tool, which is applied in the direction of measuring device, measuring fluid pressure, using liquid/vacuum degree for liquid tightness measurement, etc. Use efficiency and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

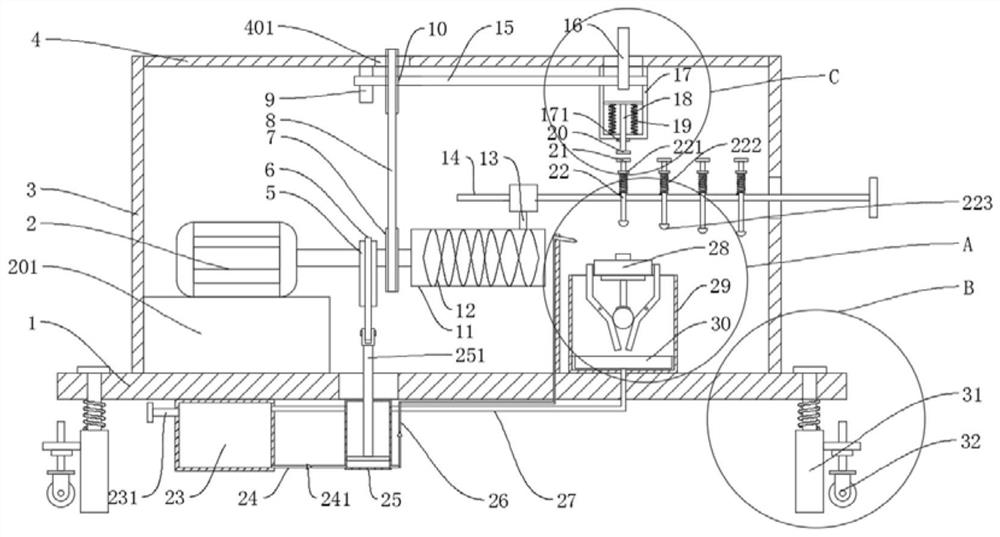

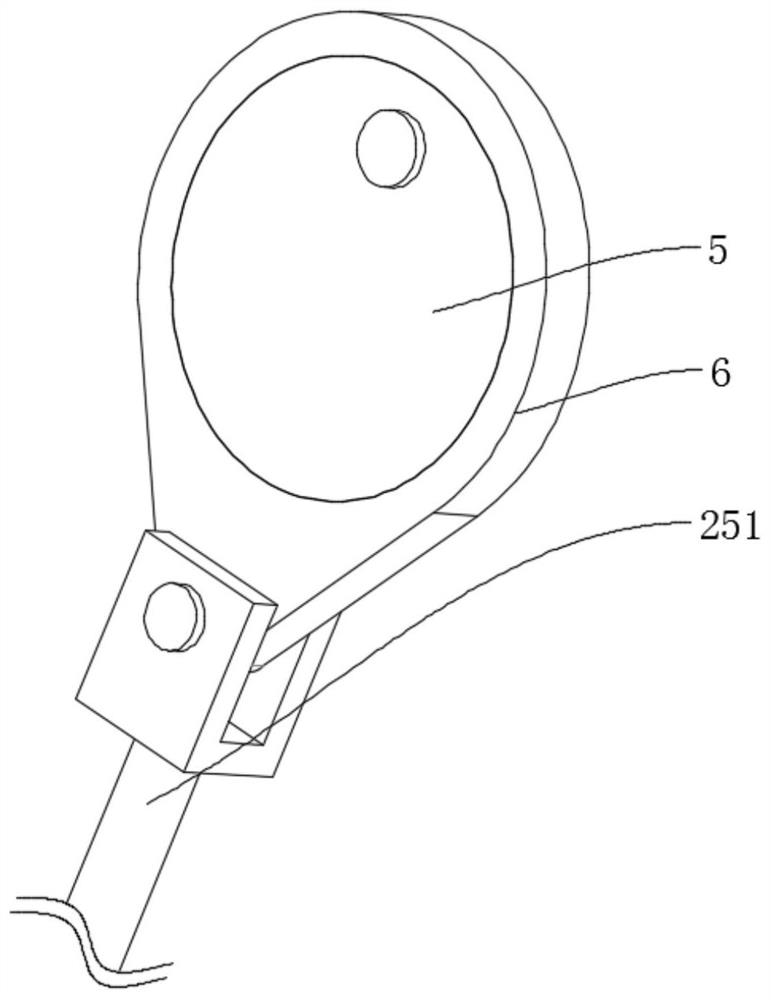

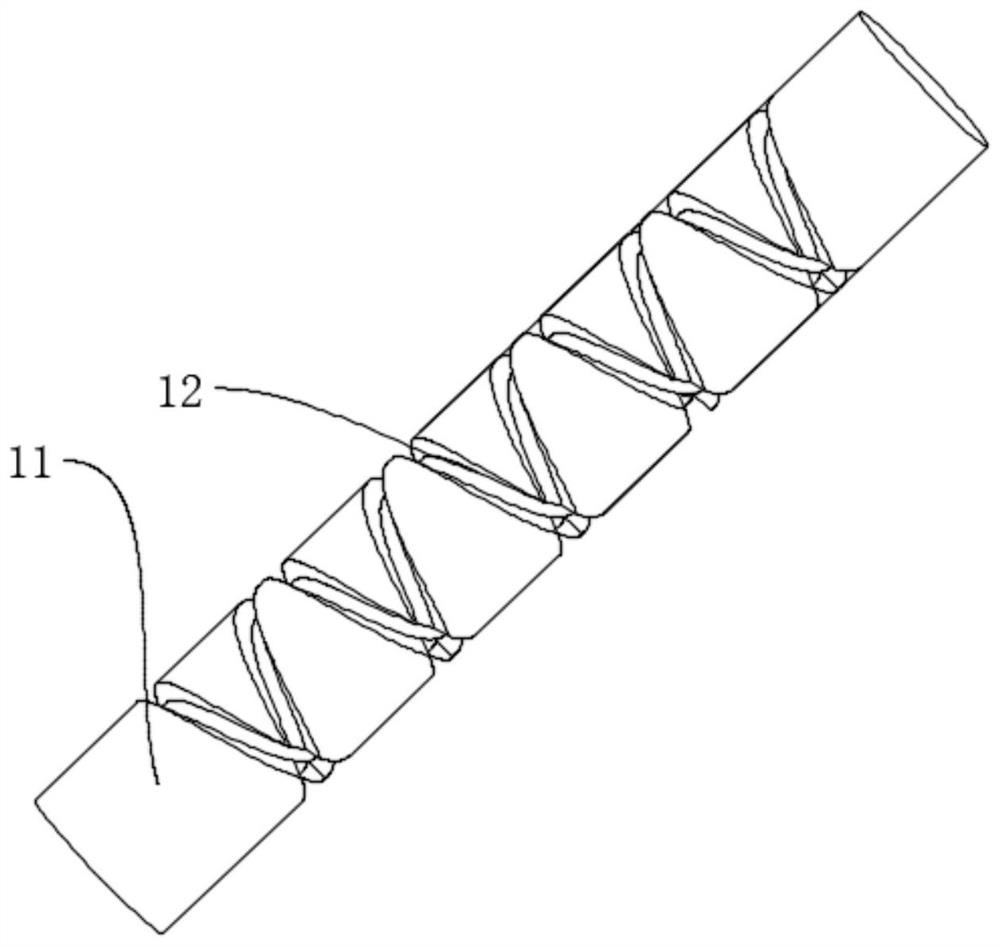

[0035] refer to Figure 1-7, a test tool for a pressure sensor and a method of use thereof, comprising a base 1, a fixed block 201, a support plate 3, a fixed frame 101, and a mold base 29 are fixedly connected to the base 1, a motor 2 is fixedly connected to the fixed block 201, and a support The top plate 4 is fixedly connected to the top plate 4, and the rotating rod 15 is connected to the top plate 4, and the motor 2 is connected to the rotating rod 15 through the transmission mechanism. , the cam 16 is fixedly connected to the rotating rod 15, the sliding frame 17 is slidably connected with a second sliding rod 18, the second sliding rod 18 is fixedly connected with a baffle plate 171 and a pressing plate 20, the baffle plate 171 is offset against the sliding frame 17, and slides The frame 17 is provided with a first spring 19, the two ends of the first spring 19 are respectively against the second slide bar 18 and the inner wall of the slide frame 17, the support plate 3...

Embodiment 2

[0043] refer to Figure 1-7 , a test tool for a pressure sensor and a method of use thereof, comprising a base 1, a fixed block 201, a support plate 3, a fixed frame 101, and a mold base 29 are fixedly connected to the base 1, a motor 2 is fixedly connected to the fixed block 201, and a support The top plate 4 is fixedly connected to the top plate 4, and the rotating rod 15 is connected to the top plate 4, and the motor 2 is connected to the rotating rod 15 through the transmission mechanism. , the cam 16 is fixedly connected to the rotating rod 15, the sliding frame 17 is slidably connected with a second sliding rod 18, the second sliding rod 18 is fixedly connected with a baffle plate 171 and a pressing plate 20, the baffle plate 171 is offset against the sliding frame 17, and slides The frame 17 is provided with a first spring 19, the two ends of the first spring 19 are respectively against the second slide bar 18 and the inner wall of the slide frame 17, the support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com