Protos unit tipping paper single rubber roller gluing system

A technology of tipping paper and single glue, applied in the field of parts and components, can solve the problems of contaminating the glue, affecting the start-up, easy falling of sundries into the glue tank, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

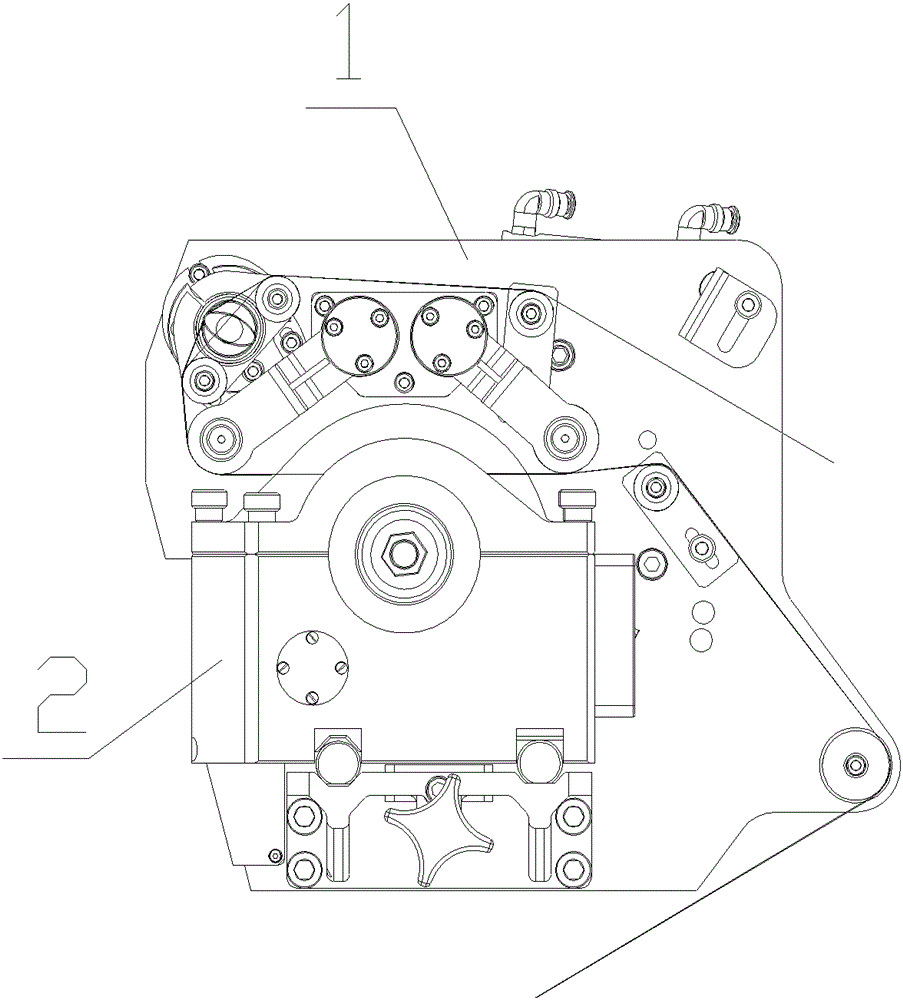

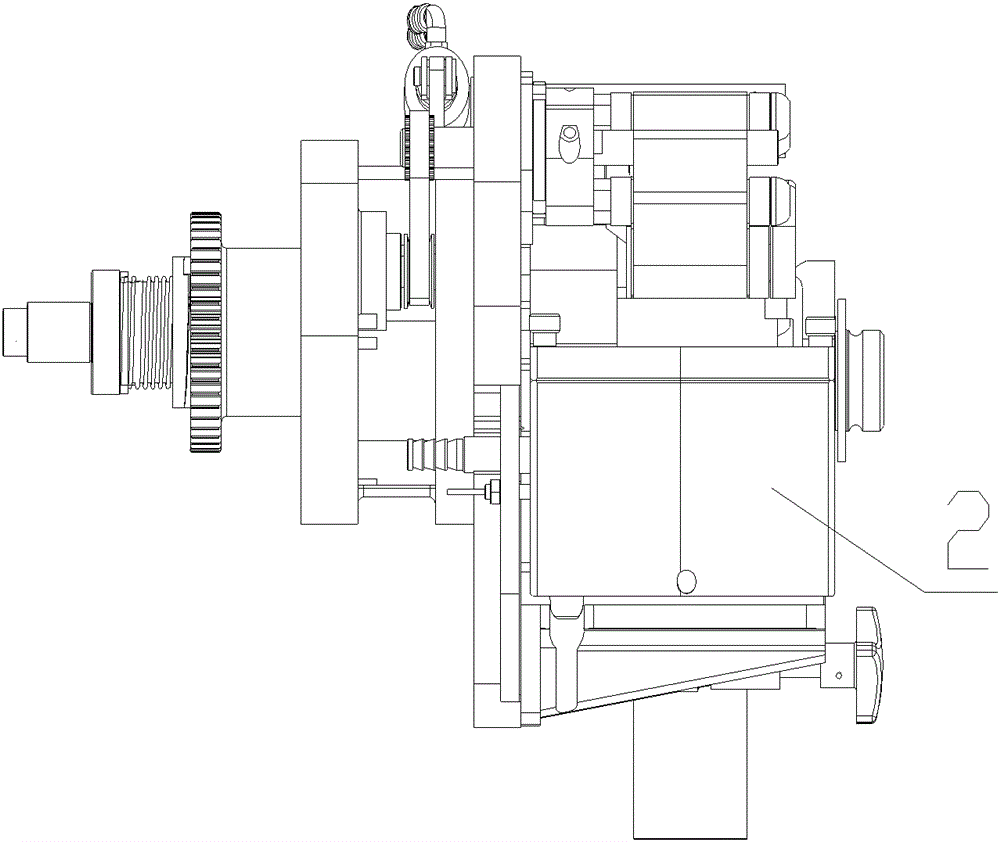

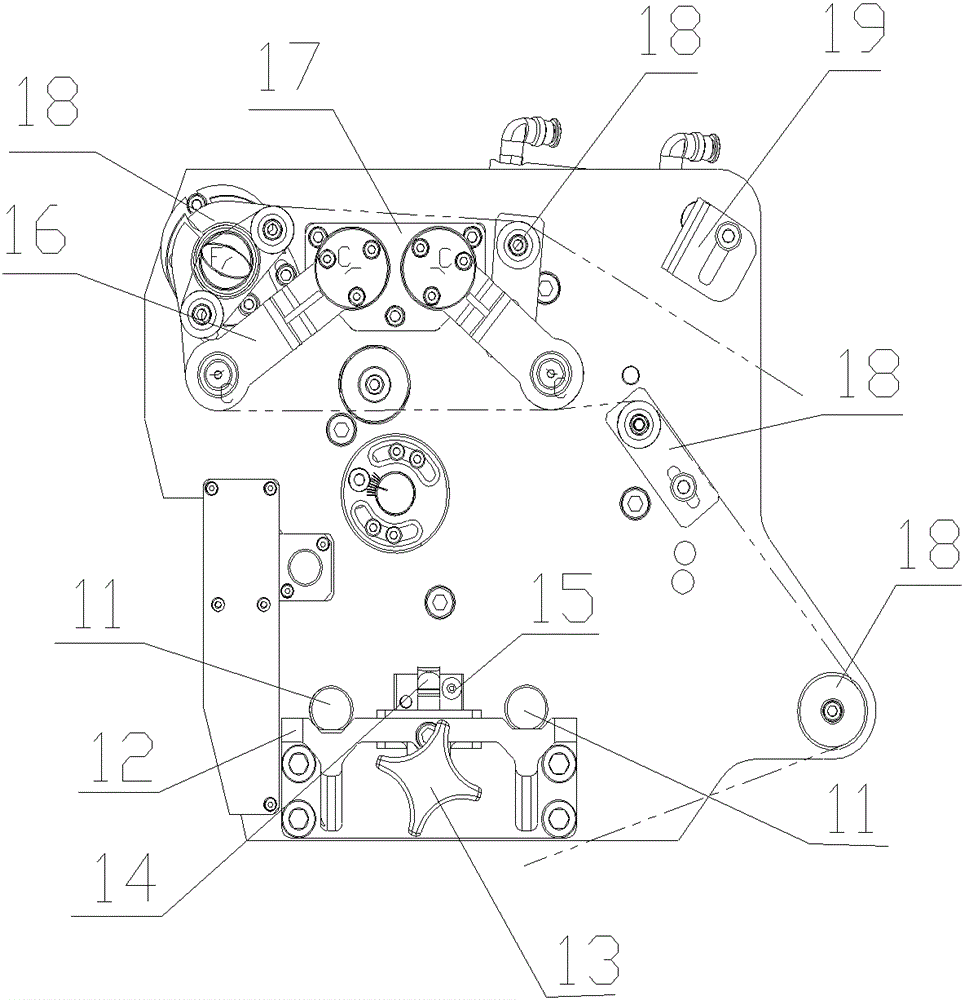

[0030] like Figure 1~4 As shown, a PROTOS unit tipping paper single rubber roller gluing system, the gluing system includes a fixed installation plate 1 and a glue supply device 2. The fixed mounting plate 1 is provided with a positioning mechanism for fixing the glue supply device 2, a paper lifting roller mechanism, a sensor 19 and a positioning pulley 18 for controlling the direction of the tipping paper tape. The glue supply device 2 is stuck on the positioning mechanism, and the paper lifting roller mechanism is set above the glue supply port of the glue supply device 2 .

[0031] like Figure 5-7 As shown, the glue supply device 2 includes a glue tank body 22 , a glue tank cover 21 , a rubber roller assembly 23 , a pick-up plate 28 , a scraper positioning assembly 25 , a scraper assembly 24 and a glue surface sensor 27 . The glue tank body 22 and the glue tank cover 21 are fixed by knurled bolts 26 . The glue tank body 22 is provided with an installation groove 221 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com