Mechanism position adjusting system and method

A technology of adjustment system and adjustment method, applied in the field of communication, can solve problems such as low work efficiency and time consumption, and achieve the effects of reducing labor cost, improving accuracy, and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The mechanism position adjustment system in the embodiment of the present invention can be applied to production equipment.

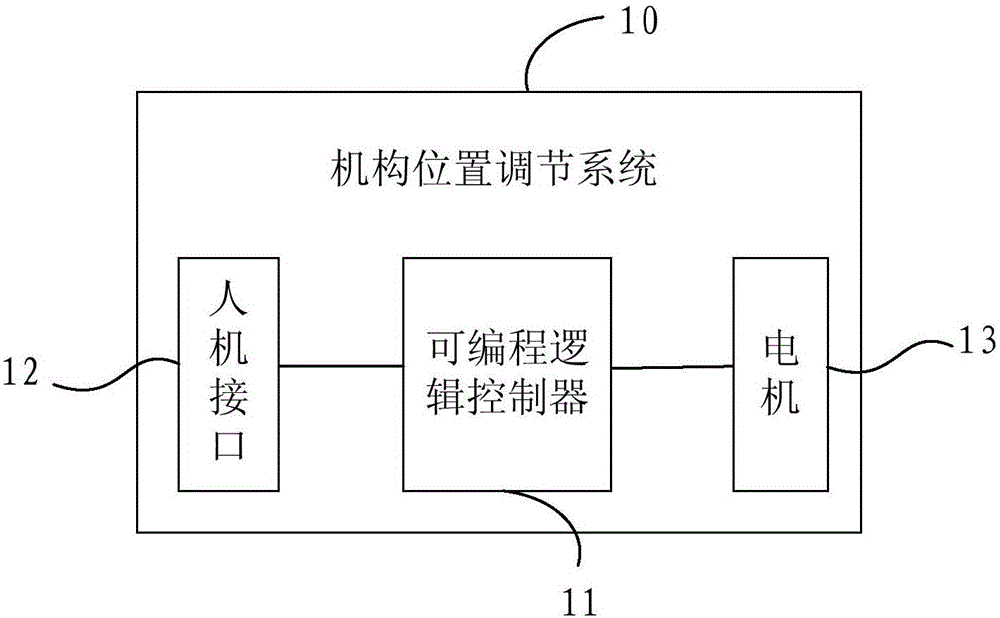

[0038] figure 1 It is a compositional block diagram of the mechanism position adjustment system in Embodiment 1 of the present invention. Such as figure 1 As shown, in this embodiment, the mechanism position adjustment system 10 may include a programmable logic controller (Programmable Logic Controller, PLC for short) 11 , a man-machine interface 12 and at least one motor 13 . Wherein, the man-machine interface 12 and the motor 13 are connected to the programmable logic controller 11 respectively, and the motor 13 adjusts the position of the corresponding mechanism on the production equipment under the control of the programmable logic controller 11 .

[0039] Among them, the man-machine interface 12 is used for man-machine interaction. The man-machine interface 12 and the programmable logic controller 11 can be connected by wire or wirelessly...

Embodiment 2

[0060] An embodiment of the present invention proposes a mechanism position adjustment method based on the above mechanism position adjustment system.

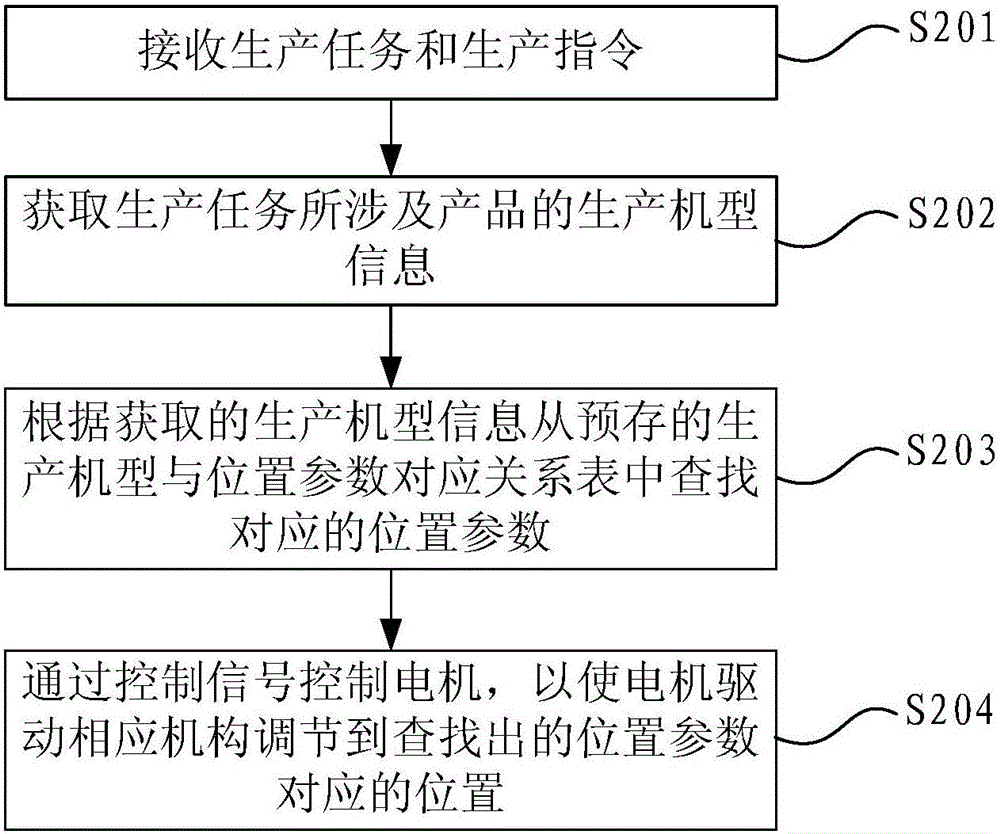

[0061] figure 2 It is a flow chart of the mechanism position adjustment method in the second embodiment of the present invention. Such as figure 2 As shown, in this embodiment, the mechanism position adjustment method may include the following steps:

[0062] Step S201, receiving production tasks and production instructions;

[0063] The production tasks and production instructions received by the programmable logic controller can be input by the user through the man-machine interface, or can be sent by the production process execution system MES of the manufacturing enterprise to the programmable logic controller through the man-machine interface or directly to the programmable logic controller. issued by the controller. The production task may include the production model information of the product to be produced.

[...

Embodiment 3

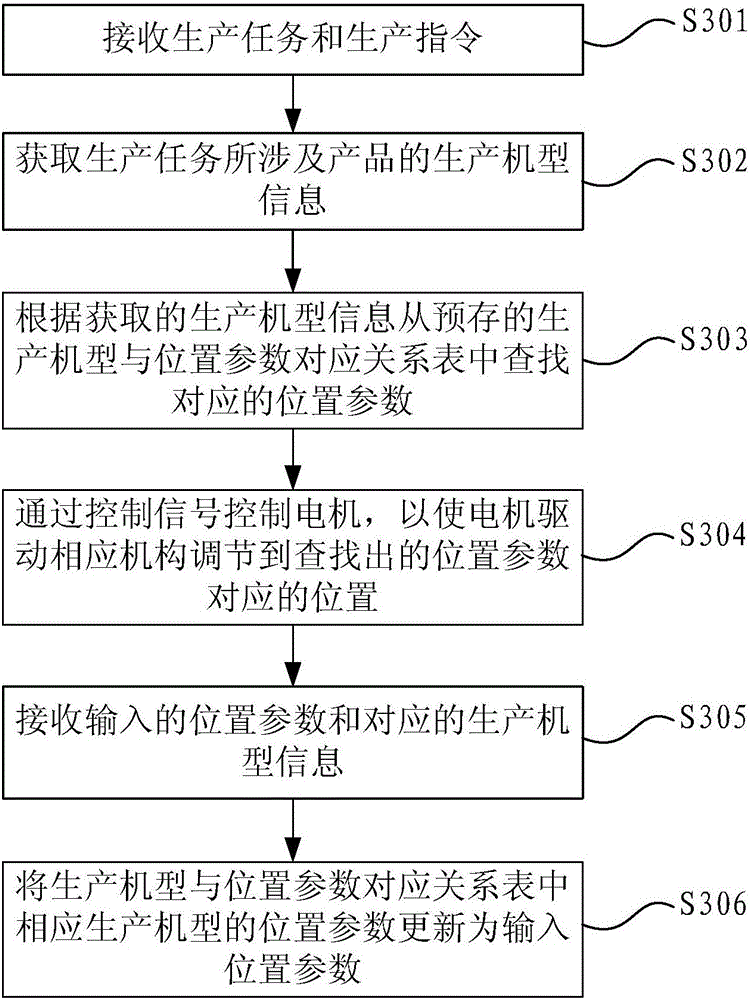

[0074] image 3 It is a flow chart of the mechanism position adjustment method in the third embodiment of the present invention. Such as image 3 As shown, in this embodiment, the mechanism position adjustment method may include the following steps:

[0075] Step S301, receiving production tasks and production instructions;

[0076] Step S302, obtaining the production model information of the product involved in the production task;

[0077] Step S303, according to the obtained production model information, look up the corresponding position parameter from the pre-stored production model and position parameter correspondence table;

[0078] Step S304, controlling the motor through the control signal, so that the motor drives the corresponding mechanism to adjust to the position corresponding to the found position parameter;

[0079] Step S305, receiving the input location parameters and corresponding production model information;

[0080] When the position parameter corre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com