Method and device using coal to directly reduce iron

A reduced iron, direct technology, used in fluidized bed furnaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

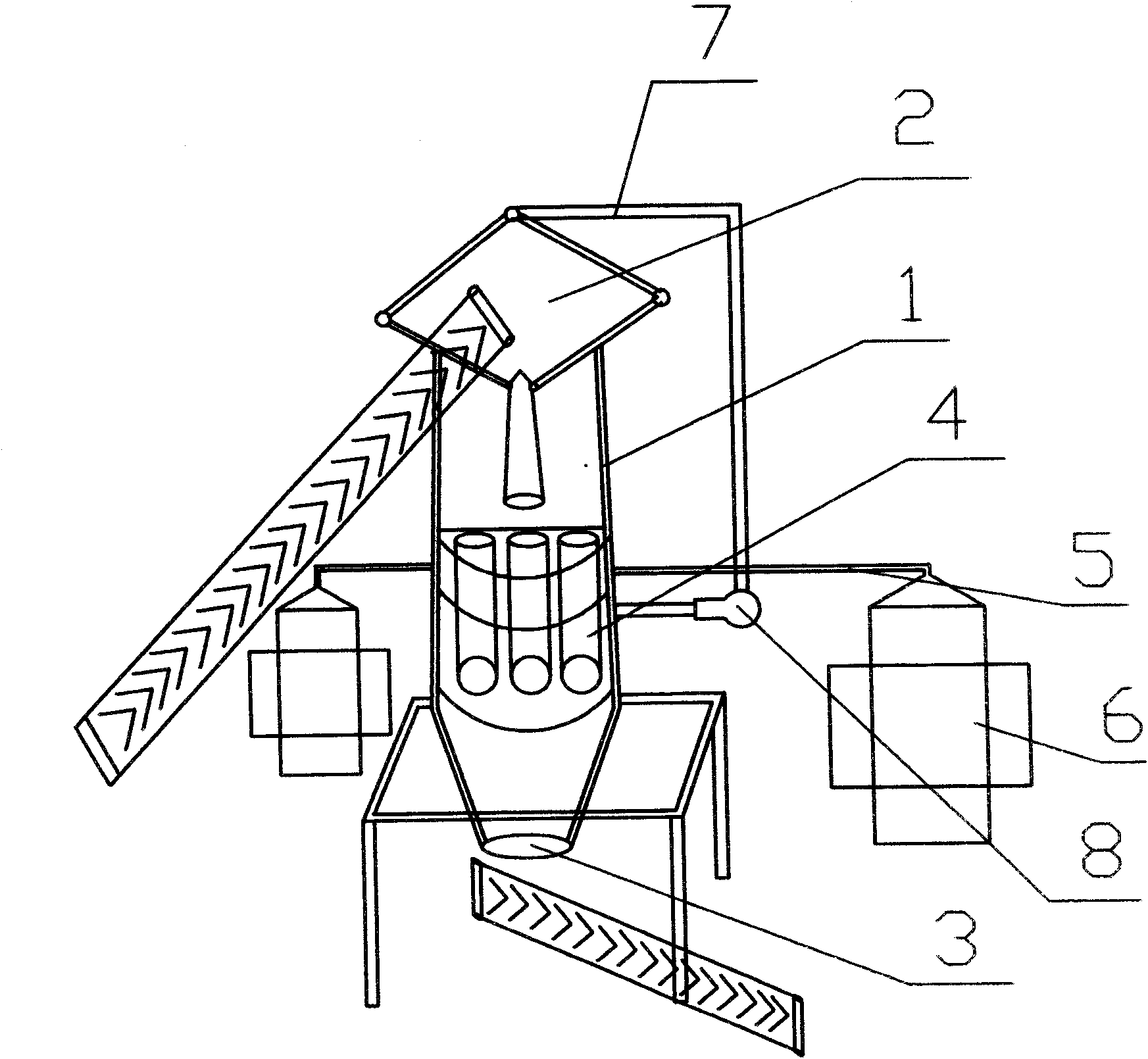

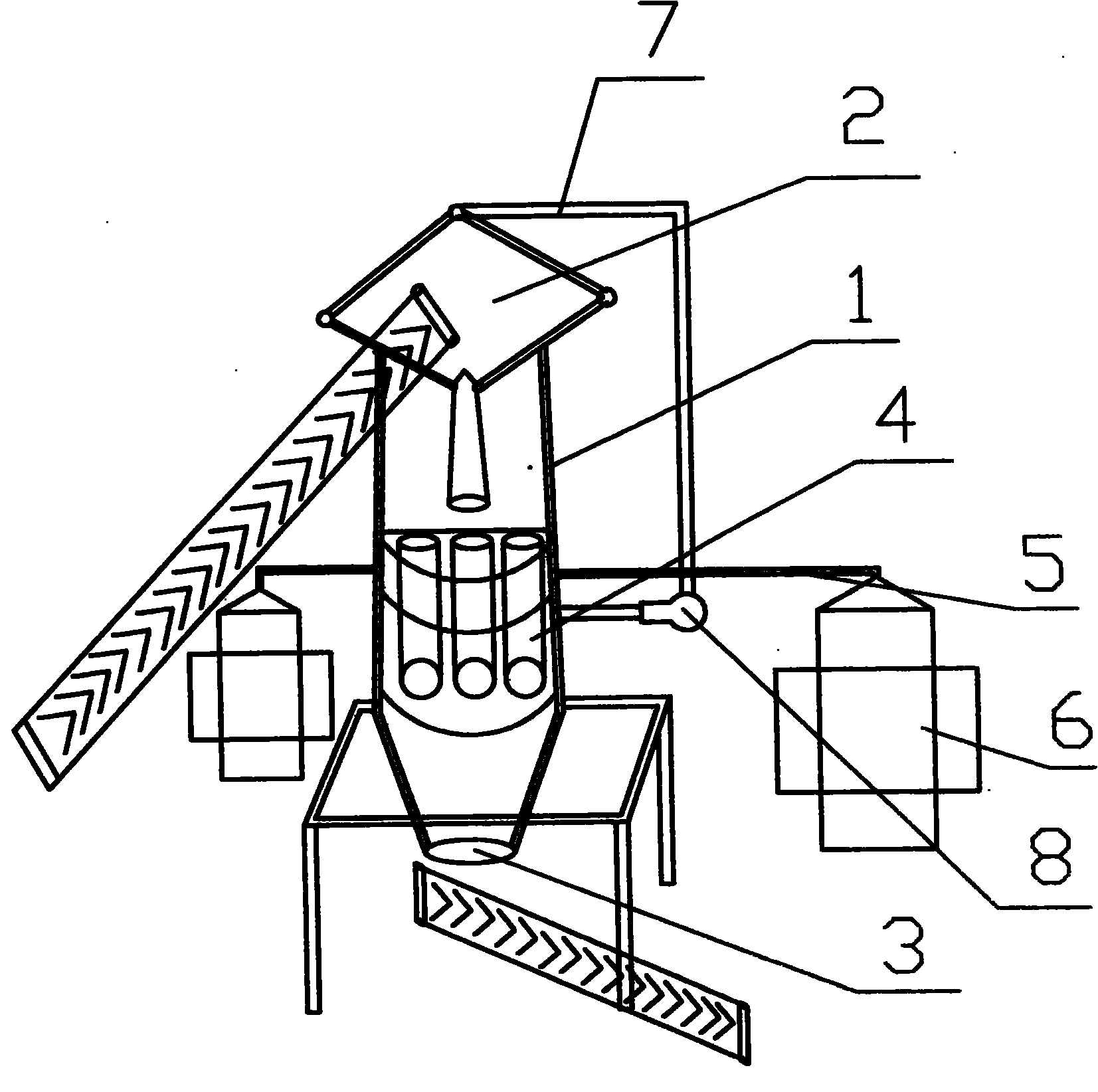

[0017] Such as figure 1 As shown, a kind of equipment of direct reduction iron of the present invention, described equipment comprises a body of furnace 1, and the top of body of furnace is feed inlet 2, and the bottom of body of furnace is discharge port 3, and described body of furnace is provided with multiple Combustion pipeline 4, gas inlet pipe 5 is respectively connected to the two sides of the furnace body, the gas inlet pipe is connected to the gas generator 6, a circulating air duct 7 is arranged on the furnace body, and a fan is installed on the circulating air duct 8.

Embodiment 2

[0019] The present invention relates to a method for directly reducing iron with coal. The method is to mix iron-making raw materials, alloy chemical raw materials and high-strength binders in a weight ratio of 100:0.5:8, knead and stir, and then Use a double-roller briquette machine to press into pellets, and then directly roast them in a vertical tubular furnace with coal gas at 1200-1250°C, and then reduce them to crystalline iron by dry distillation in an oxygen avoidance, and then crush and separate them to obtain wrought iron materials.

[0020] The iron-making raw material is one or more mixtures of iron ore powder, iron fine powder, iron oxide scale, waste steel slag from steelmaking or selected fine powder.

[0021] The alloy chemical raw materials are mixed by the following raw materials in proportion by weight: 0.5 parts of ferrosilicon manganese mixture, 3 parts of calcium oxide CaO and 10 parts of blue carbon powder.

[0022] The high-strength adhesive is prepared...

Embodiment 3

[0024] The present invention relates to a method for directly reducing iron with coal. The method comprises mixing iron-making raw materials, alloy chemical raw materials and high-strength binders in a weight ratio of 100:1:6, kneading and stirring, and then Use a double-roller briquette machine to press into pellets, and then directly roast them in a vertical tubular furnace with coal gas at 1200-1250°C, and then reduce them to crystalline iron by dry distillation in an oxygen avoidance, and then crush and separate them to obtain wrought iron materials.

[0025] The iron-making raw material is one or more mixtures of iron ore powder, iron fine powder, iron oxide scale, waste steel slag from steelmaking or selected fine powder.

[0026] The alloy chemical raw material is prepared by mixing the following raw materials in proportions by weight: 1 part of ferrosilicon manganese mixture, 2 parts of calcium oxide CaO and 10 parts of blue carbon powder.

[0027] The high-strength ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com