Patents

Literature

35 results about "Sterling silver" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sterling silver is an alloy of silver containing 92.5% by weight of silver and 7.5% by weight of other metals, usually copper. The sterling silver standard has a minimum millesimal fineness of 925. Fine silver, for example 99.9% pure silver, is relatively soft, so silver is usually alloyed with copper to increase its hardness and strength. Sterling silver is prone to tarnishing, and elements other than copper can be used in alloys to reduce tarnishing, as well as casting porosity and firescale. Such elements include germanium, zinc, platinum, silicon, and boron. Recent examples of alloys using these metals include argentium, sterlium, sterilite and silvadium.

Bracelet

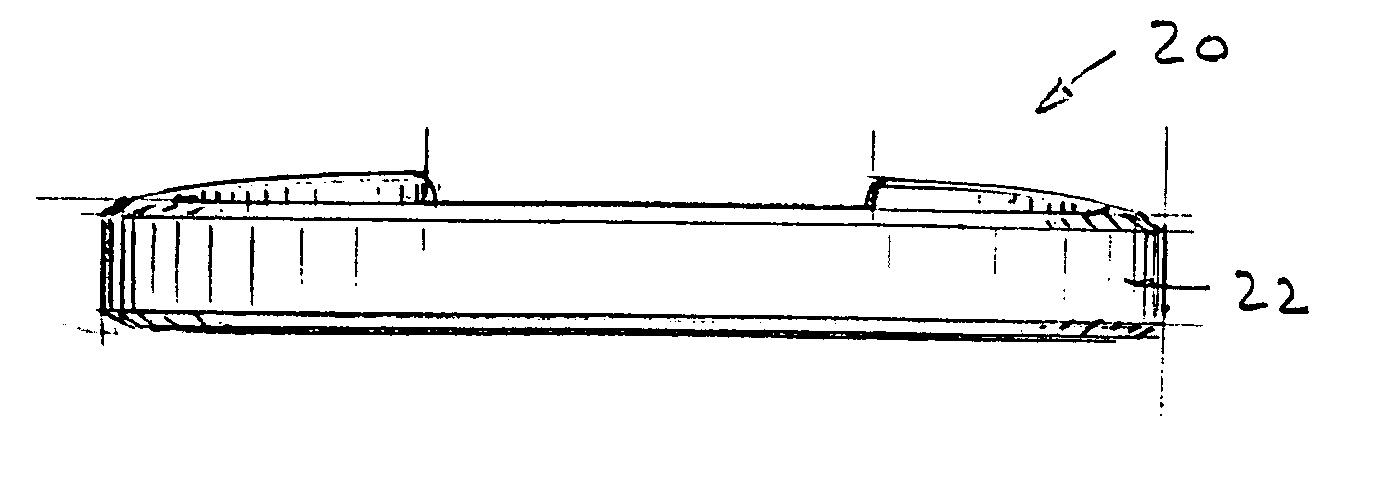

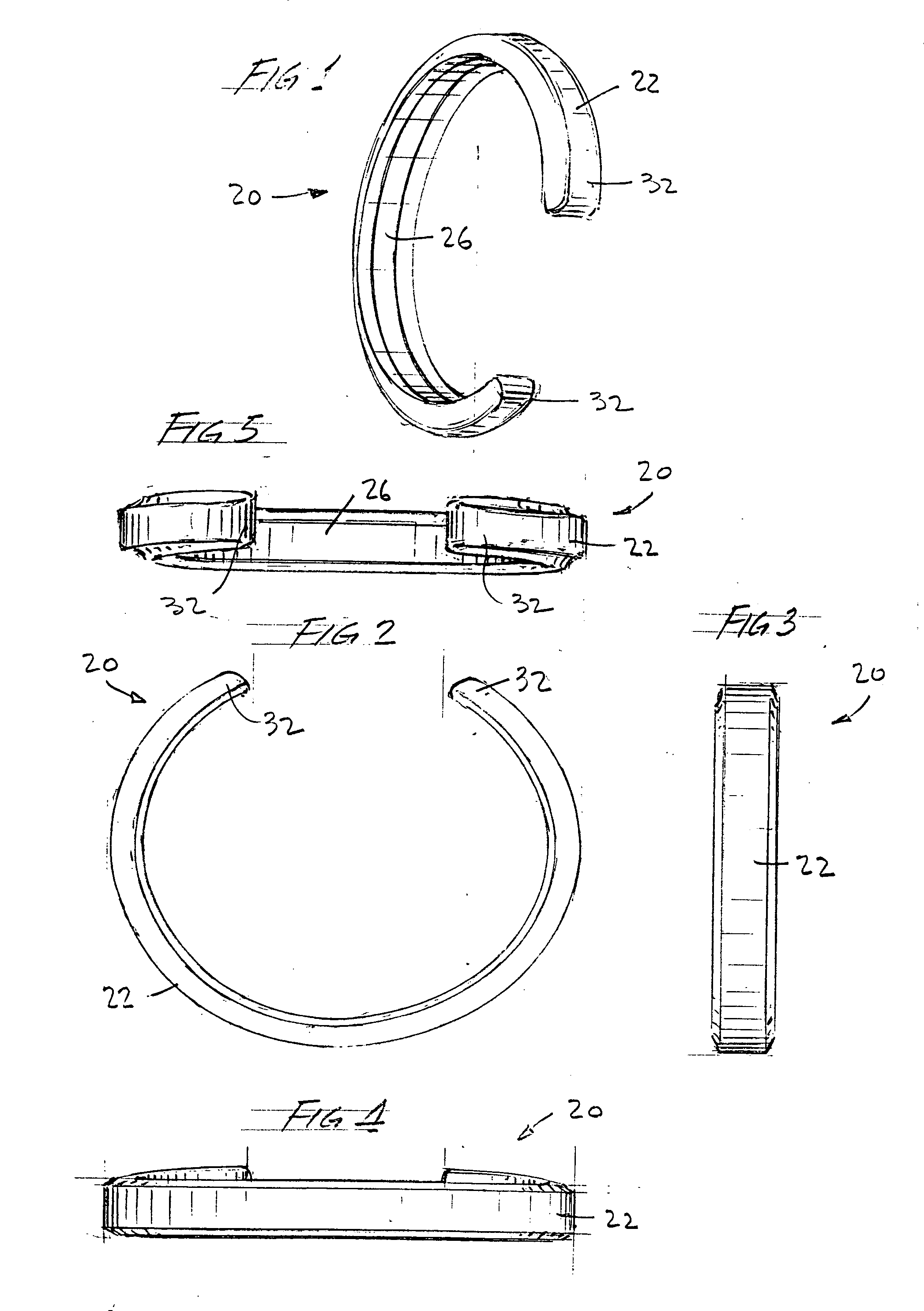

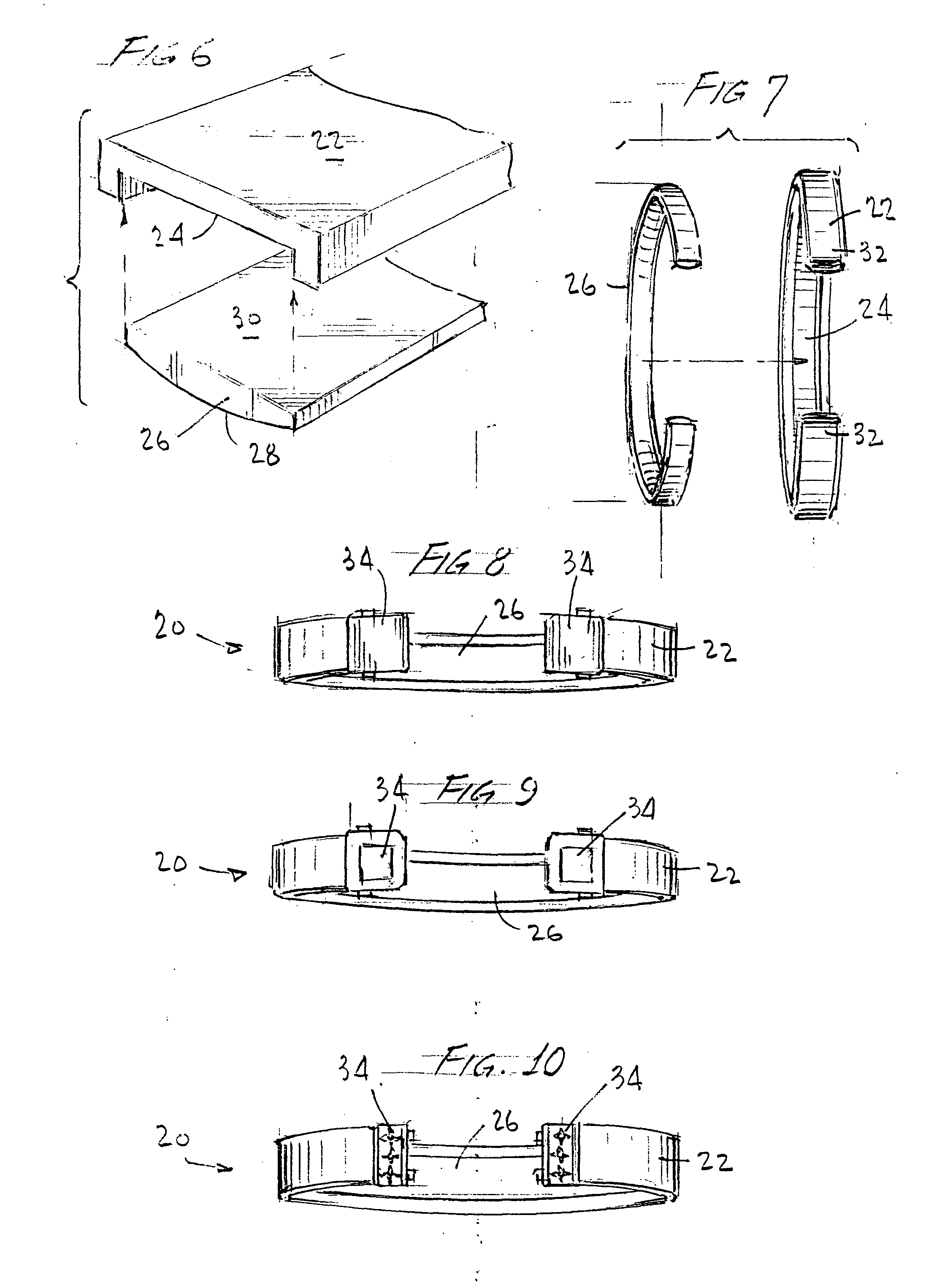

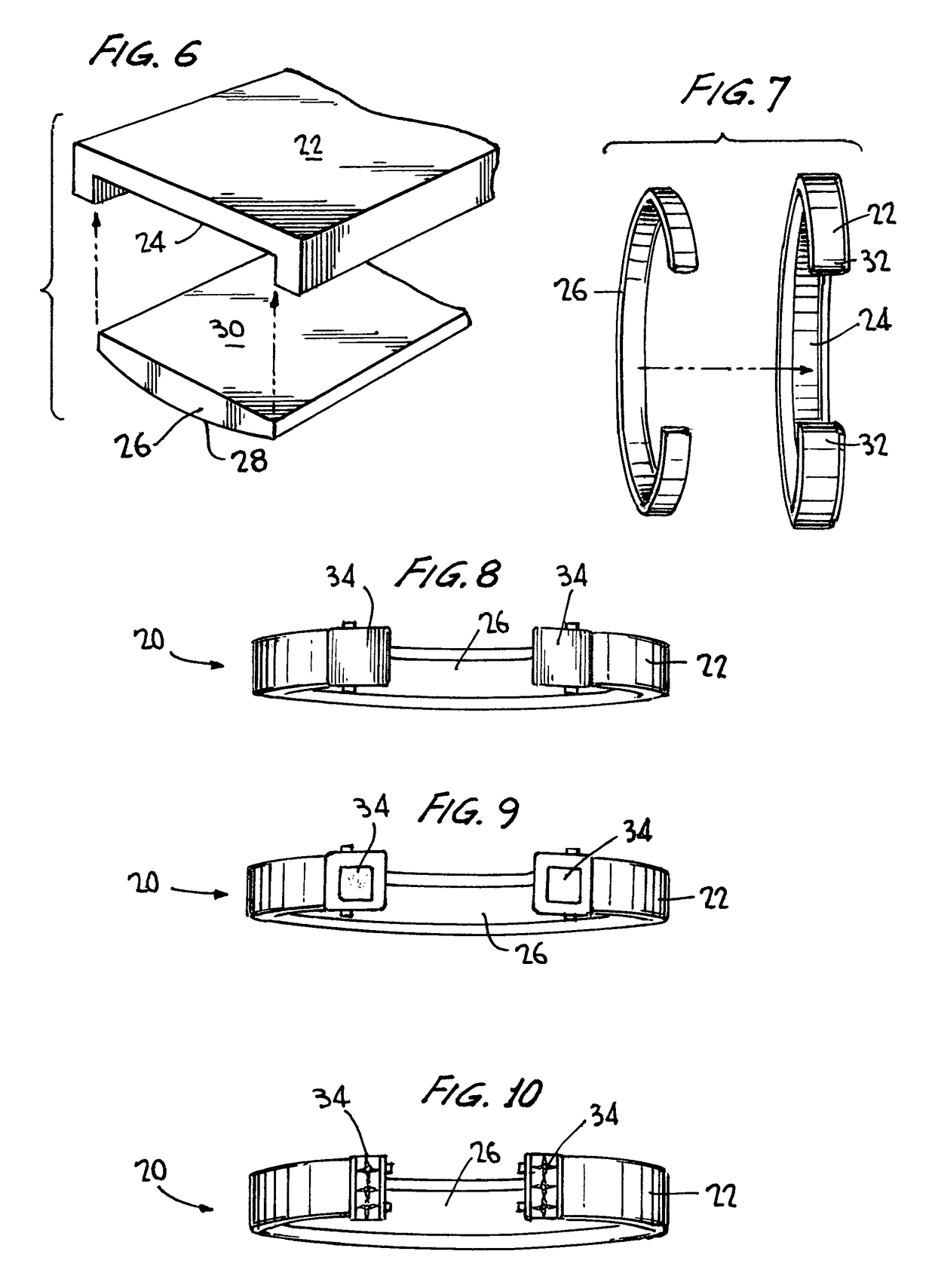

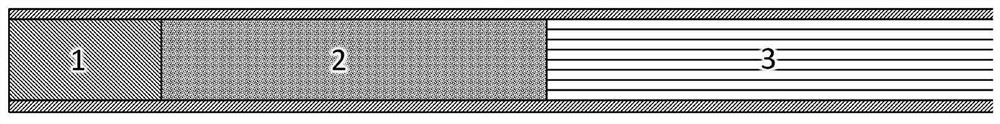

The present invention is a bracelet having an inner layer and an outer later. The inner layer of the bracelet is copper and the outer layer is another metal, preferably a precious metal such as sterling silver or gold, platinum or titanium. However, any suitable material may be used for the outer layer. Since copper can be absorbed through the skin, a wearer receives the medicinal benefits of copper while wearing a bracelet that is a fine piece of jewelry. In a preferred embodiment, the copper inner layer is a comfort fit layer.

Owner:SALTZ INC THE

Bracelet

The present invention is a bracelet having an inner layer and an outer later. The inner layer of the bracelet is copper and the outer layer is another metal, preferably a precious metal such as sterling silver or gold, platinum or titanium. However, any suitable material may be used for the outer layer. Since copper can be absorbed through the skin, a wearer receives the medicinal benefits of copper while wearing a bracelet that is a fine piece of jewelry. In a preferred embodiment, the copper inner layer is a comfort fit layer.

Owner:SALTZ INC THE

Silver-platinum alloy and methods of manufacturing same

A silver-platinum alloy formulated to provide improved tarnish resistance and hardness as compared to sterling silver. The alloy can be incorporated in various jewelry, flatware, and like articles. The alloy generally includes silver and platinum, with silver being the predominant component. In certain applications, the alloy includes about 90–95.5% silver and about 0.5–6% platinum. A small amount of gallium can also be added to the composition to provide ease of manufacture of the alloy. The resulting alloy has the favorable properties afforded by sterling silver, but also has brighter surface finish, greater tarnish resistance and increased hardness as compared to traditional sterling silver.

Owner:AMERICAN BULLION INVESTMENT

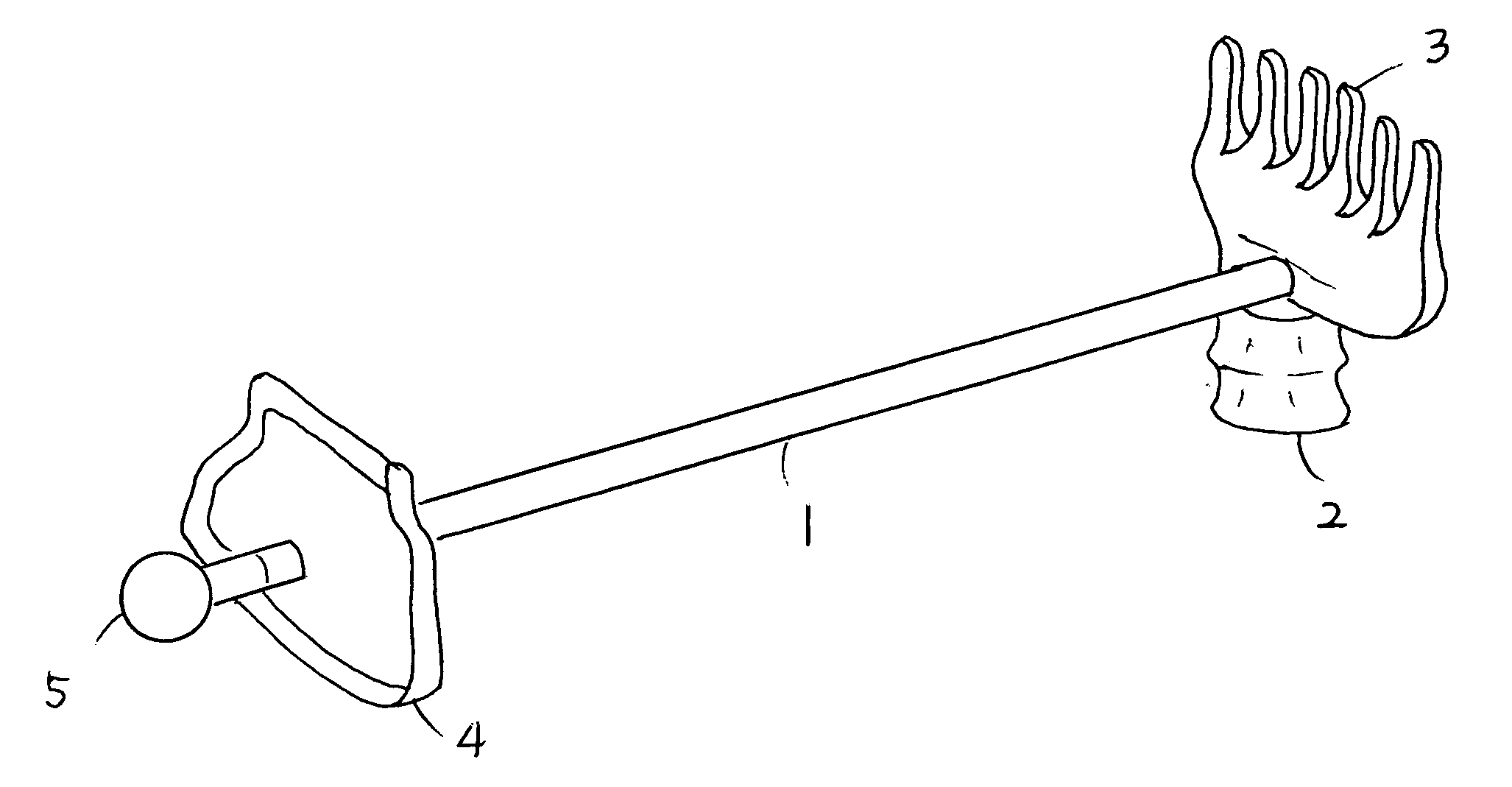

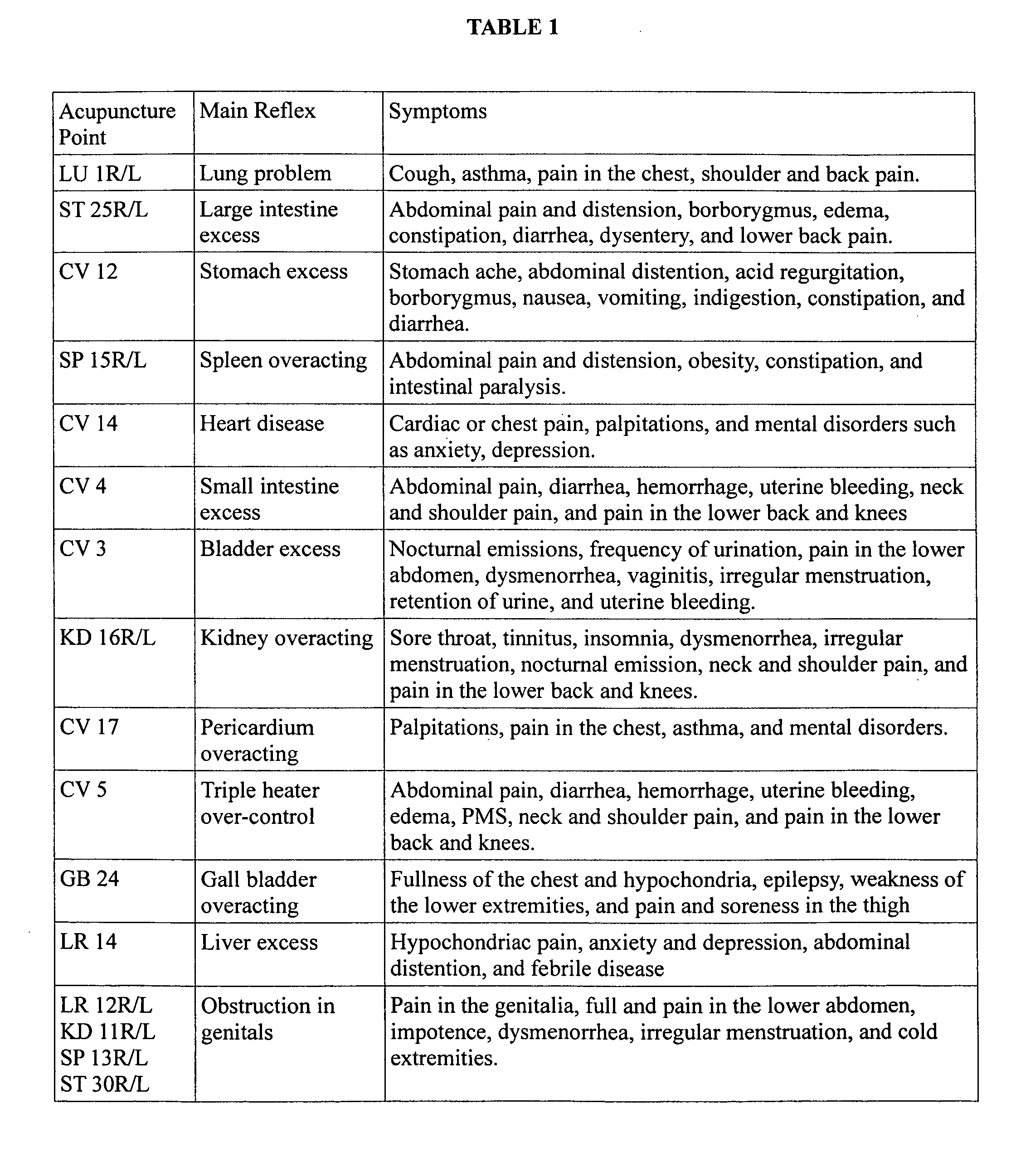

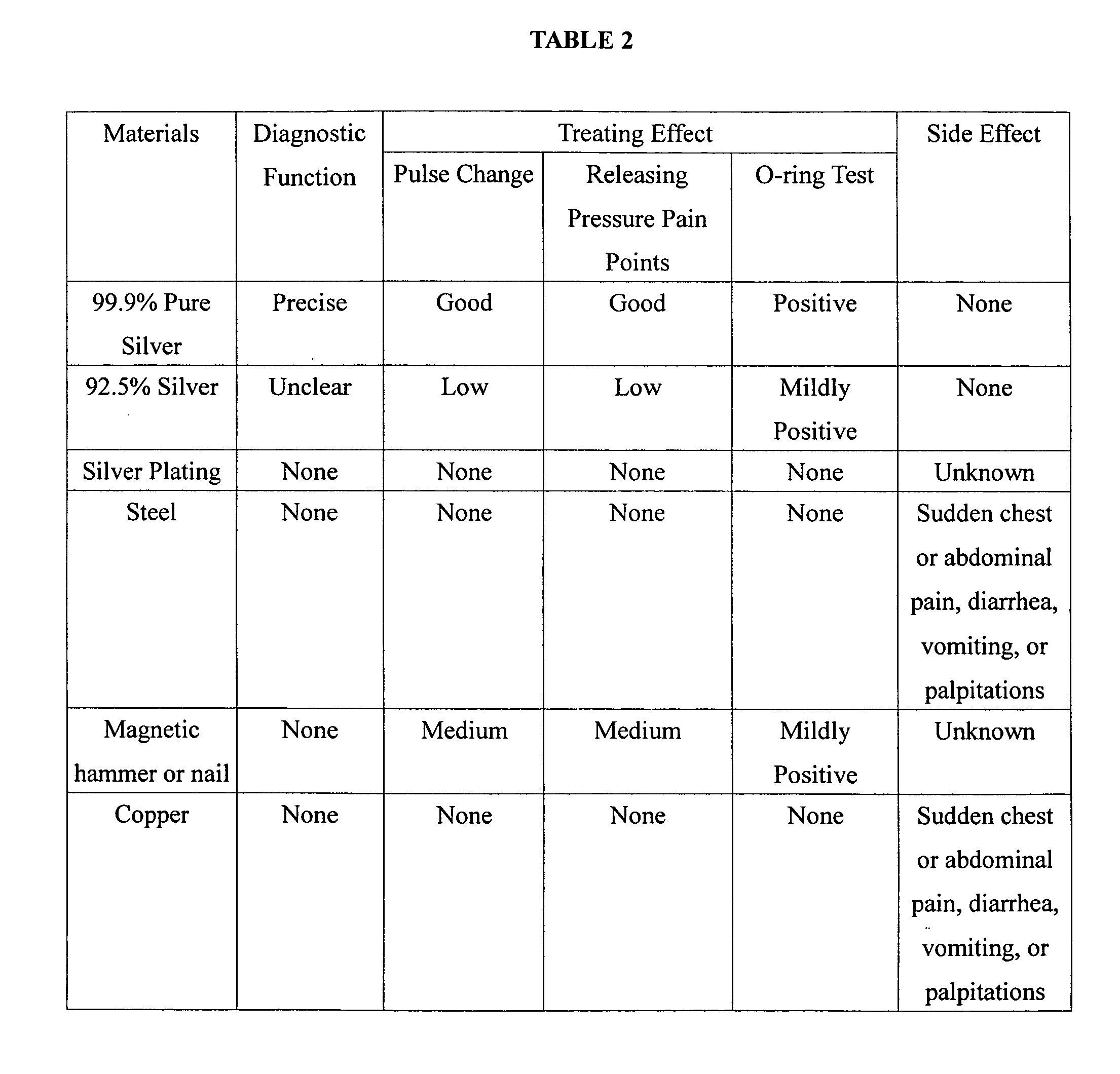

Pure silver device and method for diagnosing and treating pain in the human body

InactiveUS20120143081A1Releasing the pressure pain pointsMore powerDevices for locating reflex pointsDevices for pressing relfex pointsSide effectSterling silver

Disclosed herein are a pure silver device and a method for diagnosing and treating pain on human body. The pure silver device comprises an elongated handle, a head having both a hammer head and a comb opposed to each other, a panel, and an outwardly extending protrusion on the bottom end of the handle. The pure silver device is used to diagnose and treat pain by finding out pressure pain points on both abdominal area, at which root of pain is located, and a symptomatic area of the human body and then by releasing the pressure pain points by tapping, pressing, rubbing, combing or combining the foregoing. Owing to the highest thermal and electrical conductivity of silver, the pure silver device produces amazingly better stimulation of the pressure pain points. Therefore, the pure silver device is more effectively used for diagnosing and treating pain than other devices made out of any other material, even sterling silver and magnetic material. In addition, the pure silver device is portable and useful in that anyone can diagnose and treat himself or herself anytime and anyplace. The pure silver device and the method are simple, easy, safe without any side effects and medical risks, and economical.

Owner:LYU HYUNG WOO

Precious metal composition, method and article of jewelry comprising same

The present invention is related to a novel sterling silver compound for use in vermeil jewelry and other articles of manufacture. The compound includes an alloy composed of at least 92.5% by weight of silver, up to 7.5% by weight of gold, and the remainder in copper. The invention further relates to an article of jewelry including at least 92.5% by weight of silver, up to 7.5% by weight of gold, and the remainder in copper. The invention also relates to a method for making an article. The method includes providing a vessel and adding 3.75% by weight of gold, 94.0% by weight of silver, and 2.25% by weight of copper to the vessel. The method also includes melting the metals and mixing them until a homogenous mixture is formed. The method further includes pouring the homogenous mixture into a mold to form a semi-finished article and plating the semi-finished article with 18K rose gold.

Owner:SENO JEWELRY

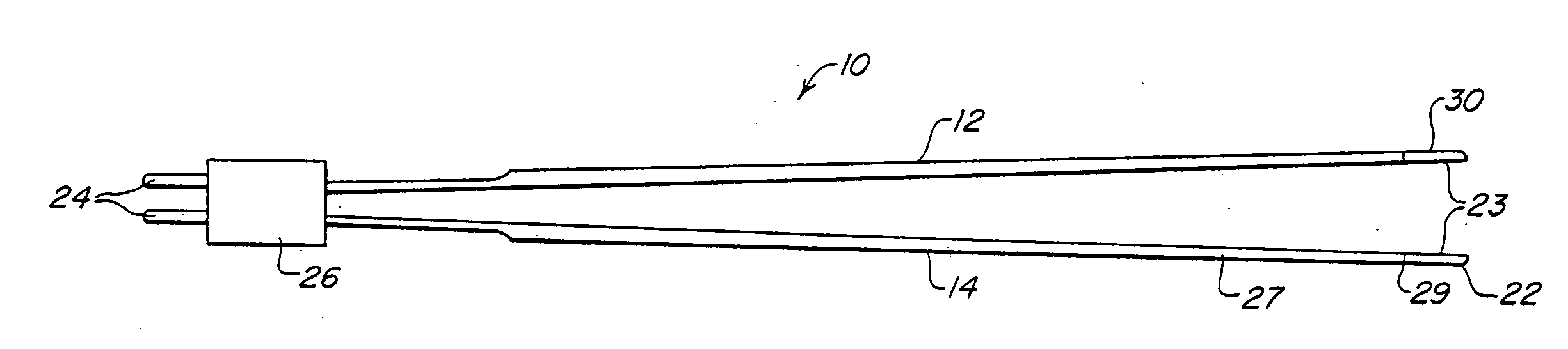

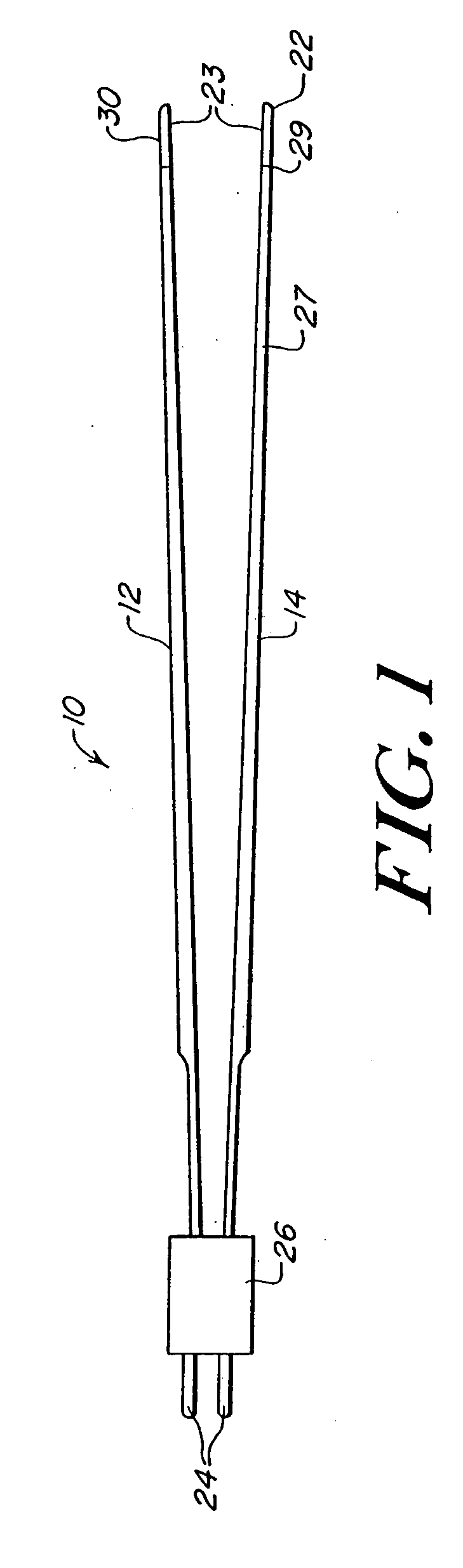

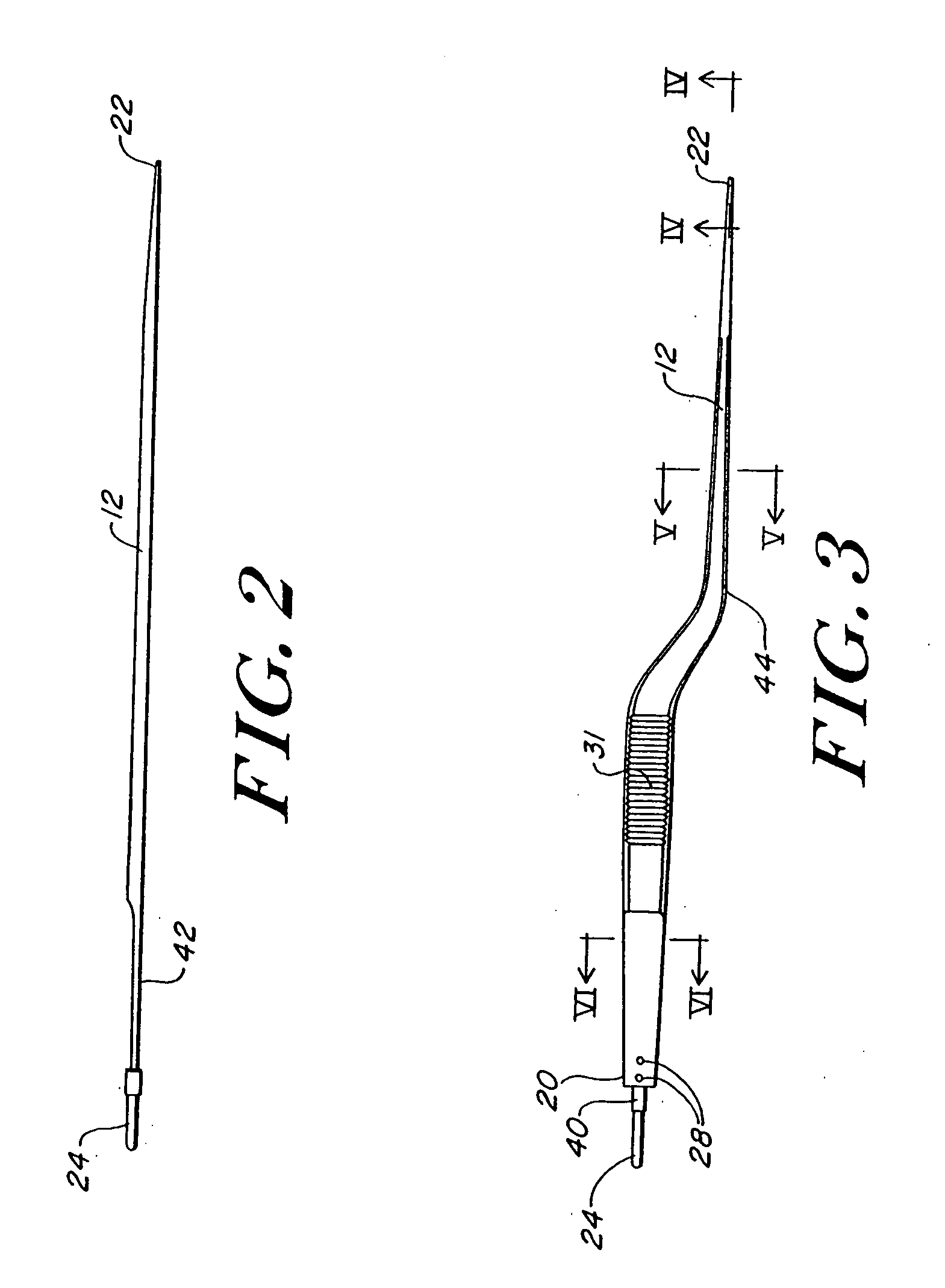

Electro-surgical forceps having fully copper-plated tines and process for manufacturing same

InactiveUS20070208341A1Improve thermal conductivityImprove conductivitySurgical instruments for heatingCoatingsSterling silverForceps

An electro-surgical forceps has a pair of tines. At least one of the tines has an inner core of a metal such as stainless steel, nickel, titanium, aluminum, or alloys such as sterling silver, and an outer plating of copper or a copper alloy having a thermal conductivity and an electrical conductivity greater than the core material. The outer plating covers all or substantially all of the tine. The outer plating is suitably formed by an electroplating process.

Owner:KIRWAN SURGICAL PRODS

Non-rusting silver alloy and preparation method thereof

The invention provides non-rusting silver alloy. The non-rusting silver alloy comprises, by weight, 90.0-92.5% of silver, 0.5-5% of copper, 0.5-2.0% of zinc, 0.2-1.1% of tin, 1.0-3.0% of indium and 0.1-6% of germanium. The invention further provides a preparation method for the non-rusting silver alloy and the application of the non-rusting silver alloy. According to the non-rusting silver alloy and the preparation method thereof, the compositions are simple and do not contain precious metal and rare metal; the non-rusting silver alloy is suitable for making contact with human body skin; good machinable property is achieved; the non-rusting property of the non-rusting silver alloy is over twice that of Sterling silver, so that the non-rusting silver alloy is suitable for being applied to the industries of jewelries, decorations and the like.

Owner:SHANGHAI JIAO TONG UNIV

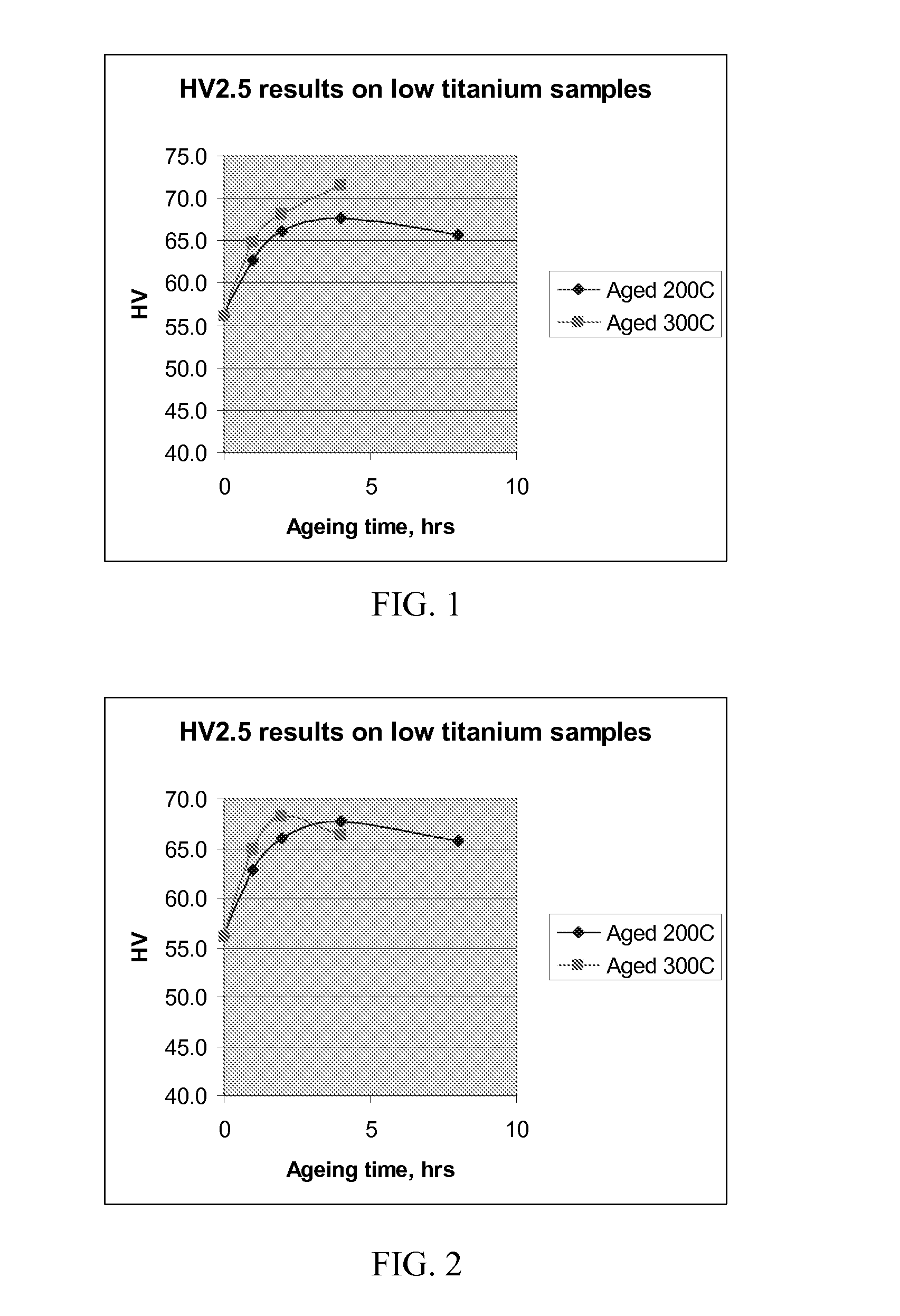

Reversibly age hardenable, palladium containing tarnish resistant sterling silver alloys

A silver-based alloy composition which is soft and workable in an annealed condition, is hardenable through heat treatment, and is tarnish resistant. The preferred embodiment of the composition of the present invention includes a small percentage of palladium and a reduction from typical percentages of copper found in a sterling silver alloy. In one embodiment the silver-based alloy includes no copper at all.

Owner:RICHLINE GRP

Reversibly age hardenable, palladium containing tarnish resistant sterling silver alloys

A silver-based alloy composition which is soft and workable in an annealed condition, is hardenable through heat treatment, and is tarnish resistant. The preferred embodiment of the composition of the present invention includes a small percentage of palladium and a reduction from typical percentages of copper found in a sterling silver alloy. In one embodiment the silver-based alloy includes no copper at all.

Owner:RICHLINE GRP

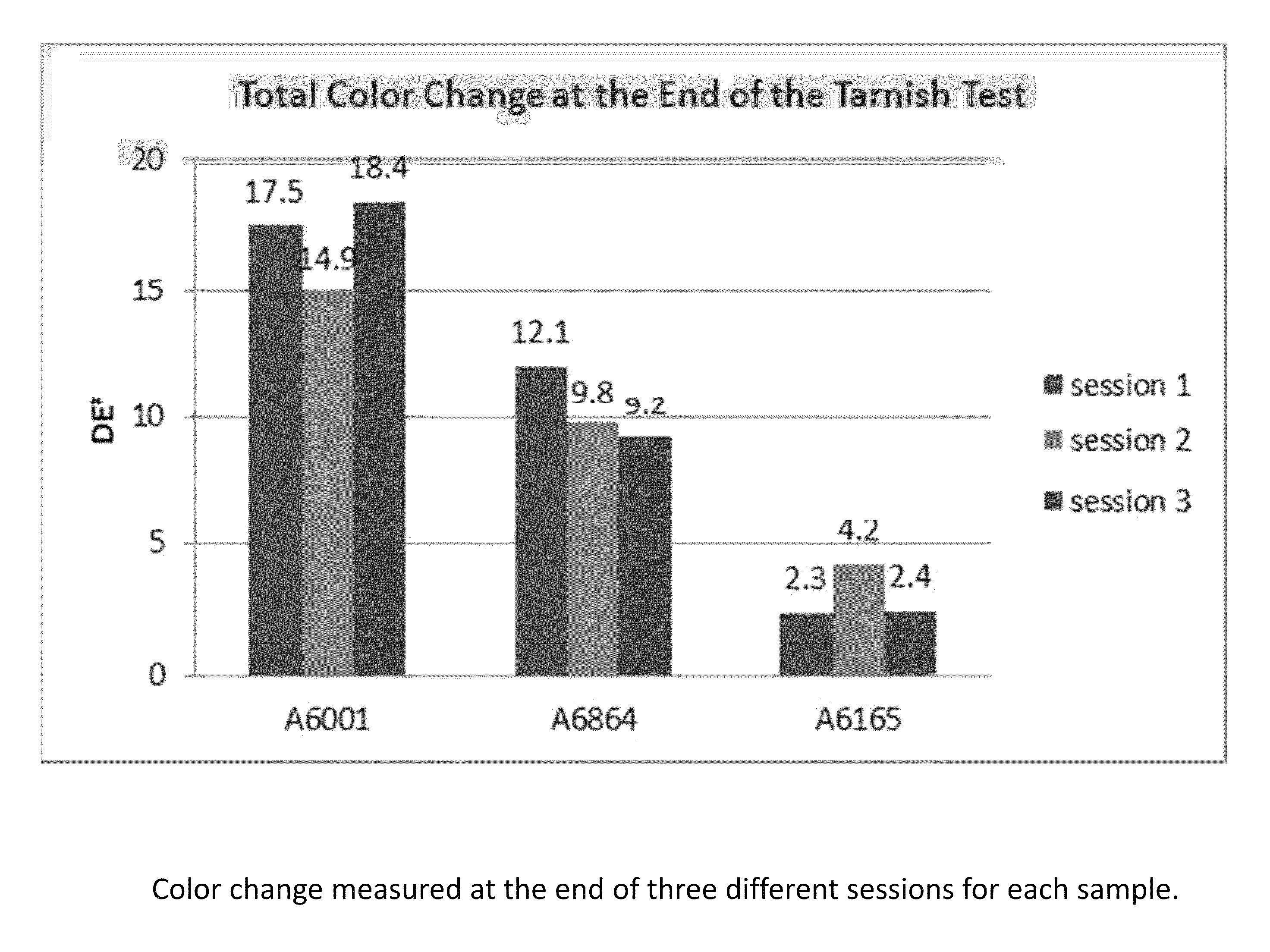

Tarnish-resistant sterling silver alloys

InactiveUS20140003992A1Noteworthy combination of hardness and tarnish resistanceGood colorAngiosperms/flowering plantsSterling silverAlloy

Titanium sterling silver alloy compositions that exhibit enhanced tarnish resistance while maintaining an acceptable hardness. Applications and manufacturing methods thereof are disclosed.

Owner:KF LICENSING

Silver alloy compositions

Fire-scale resistant, work-hardenable-jewelry, silver-alloy compositions having desirable properties of reduced fire scale, reduced porosity, oxide formation and reduced grain size relative to traditional sterling silver alloys while providing improved work hardening performance. These compositions contain at least 86% by weight silver, 0-5-7.5% by weight copper, 0.07-6% by weight of a mixture of zinc an silicon with silicon being present in an amount from about 0.02 to about 2.0% by weight, and from about 0.01 to no more than 2.0% by weight germanium.

Owner:ECCLES ANTHONY

Silver-platinum alloy and methods of manufacturing same

A silver-platinum alloy formulated to provide improved tarnish resistance and hardness as compared to sterling silver. The alloy can be incorporated in various jewelry, flatware, and like articles. The alloy generally includes silver and platinum, with silver being the predominant component. In certain applications, the alloy includes about 90-95.5% silver and about 0.5-6% platinum. A small amount of gallium can also be added to the composition to provide ease of manufacture of the alloy. The resulting alloy has the favorable properties afforded by sterling silver, but also has brighter surface finish, greater tarnish resistance and increased hardness as compared to traditional sterling silver.

Owner:AMERICAN BULLION INVESTMENT

Silver-lanthanum-calcium alloy bonding wire and manufacturing method thereof

InactiveCN103996668ALow priceReduce performanceSemiconductor/solid-state device detailsSolid-state devicesSterling silverBusbar

The invention discloses a silver-lanthanum-calcium alloy bonding wire and a manufacturing method thereof. According to the bonding wire, high sterling silver is used as a main part material, and a lanthanum metal material, a calcium metal material and a gold metal material are included. The bonding wire comprises, by weight, 95-97% of silver, 2-3% of lanthanum, 0.5-1% of calcium and 0.5-1% of gold. The manufacturing method includes the steps that the high sterling silver with the purity being larger than 99.9999% is extracted to be prepared into silver alloy ingots and then to be prepared into cast condition silver-lanthanum-calcium alloy busbars, the alloy busbars are pulled to be wires of about 1 mm, heat treatment is completed, and then precision drawing, heat treatment and washing are conducted so that silver-lanthanum-calcium alloy bonding wires of different specifications can be manufactured.

Owner:江西蓝微电子科技有限公司

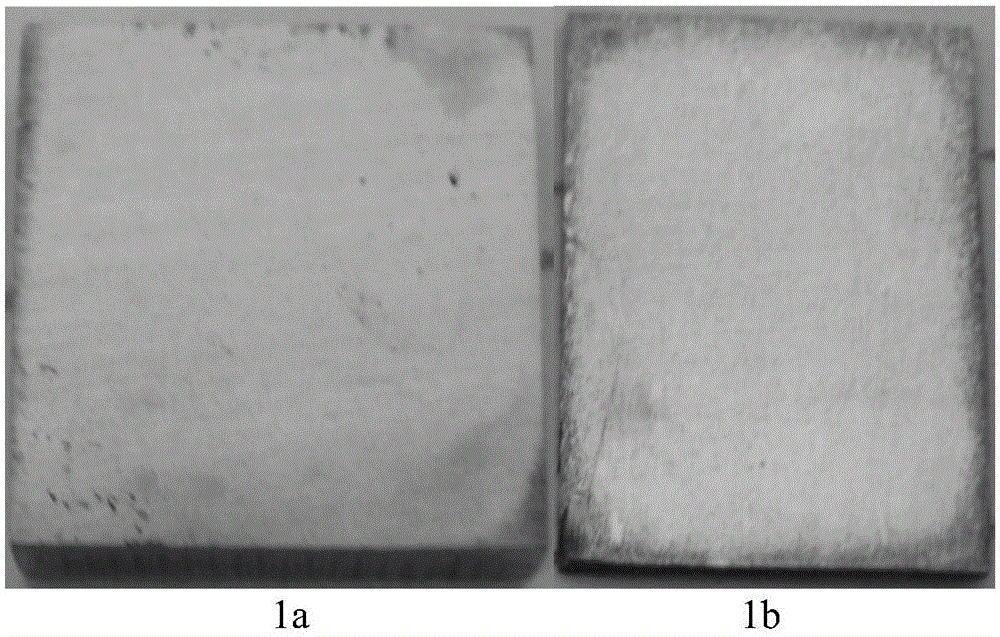

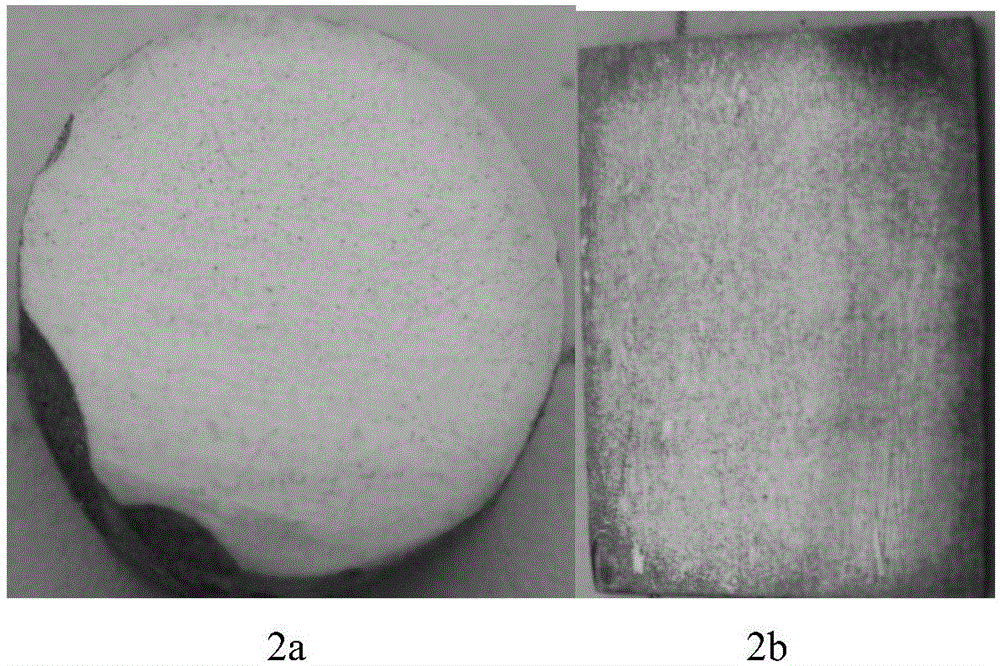

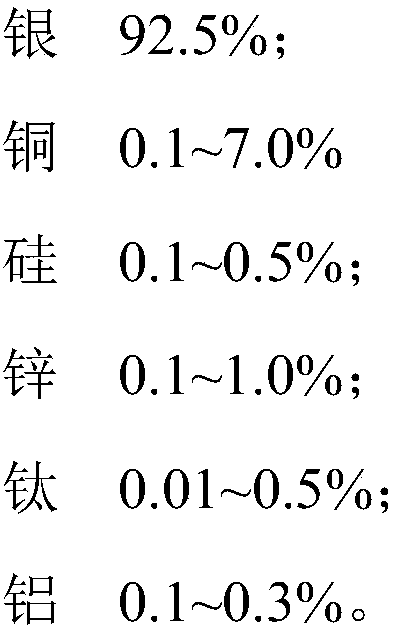

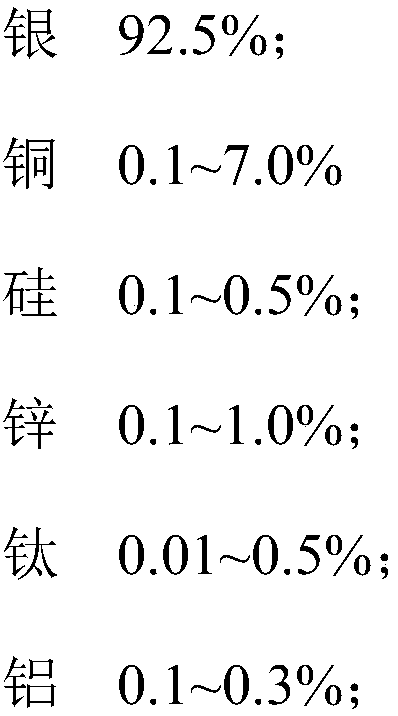

Silver alloy and manufacturing technology and application thereof

The invention belongs to the technical field of silver alloy and specifically discloses a silver alloy and a manufacturing technology thereof. The silver alloy comprises the following components in percentage by weight: 92.5% of silver, 0.1-7.0% of copper, 0.1-1.0% of silicon, 0.1-1.0% of zinc, 0.01-0.5% of titanium, and 0.1-0.3% of aluminum. The preparation technology comprises the following steps: mixing the components of the silver alloy to obtain a mixture; smelting the mixture in a vacuum condition to obtain melt; under the protection of an inert atmosphere, pouring the melt into an alloysheet ingot; and sequentially performing homogenization heat treatment, re-annealing treatment and hardening heat treatment on the alloy sheet ingot, to obtain the silver alloy. The silver alloy disclosed by the invention is at least twice stronger than sterling silver in the ability of resisting vulcanization blackening, and has relatively strong as-cast hardness and high-temperature oxidation resistance and high processability; and moreover, the hardness reaches 150HV or above and reaches the hardness of stainless steel.

Owner:依波精品(深圳)有限公司

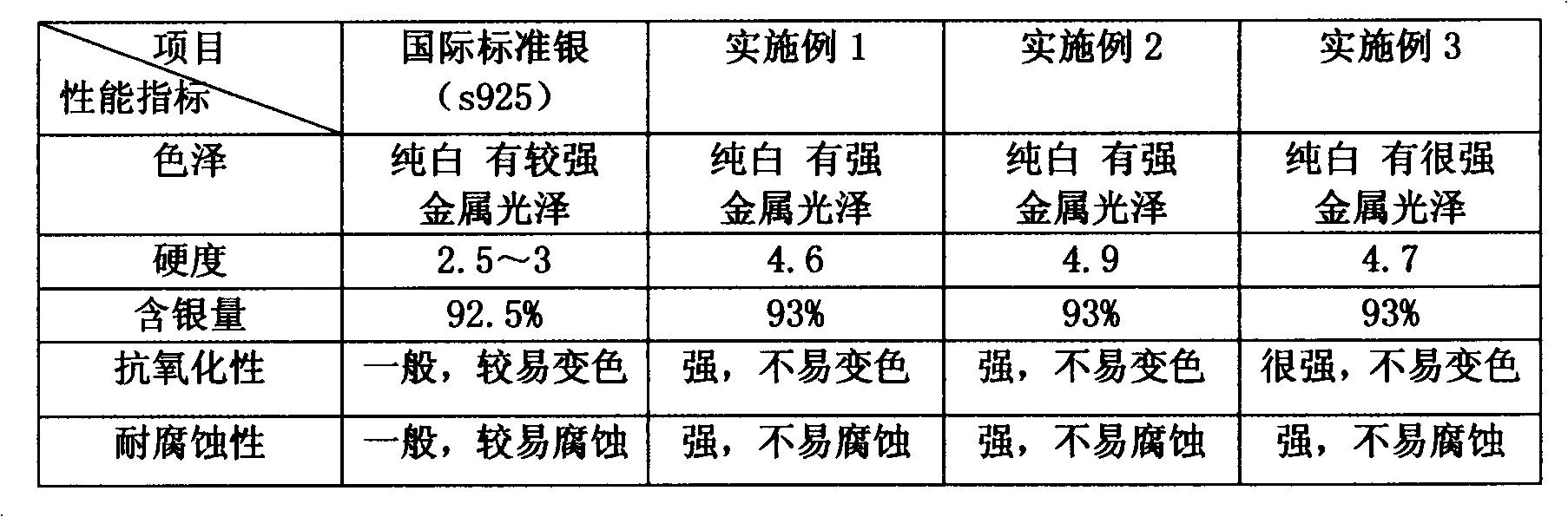

Silver ornament alloy taking silver as main component

The invention relates to a silver ornament alloy, particularly relates to the silver ornament alloy taking silver as a main component, and belongs to the technical field of non-ferrous metal. The silver ornament alloy taking silver as the main component is prepared by taking the following components by weight part: 93-95 parts of silver, 2-4 parts of copper, 1-3 parts of titanium and 1-3 parts of chromium, wherein the purities of all the components are 99.9%-99.99%. The silver ornament alloy is prepared according to the following steps of: weighting the raw materials by weight part of all components; placing the components into a vacuum furnace in turn; melting in a vacuum electric arc furnace with the vacuum degree at 0-5Pa and the temperature at 1860-1890 DEG C; keeping the temperature for 1 hour, and then uniformly stirring; pouring and placing into a mould; and cooling at a speed of 30-45 min. A detection result shows that the silver ornament alloy taking silver as the main component has the advantages that the silver ornament alloy is brighter (whiter) than the s925 international sterling silver, the silver ornament alloy is characterized by anti-oxidation and corrosion resistance and is harder, the hardness is 4.5-5.2, and the silver ornament alloy is more durable and attractive and has a better health-care function for the human body.

Owner:金保全

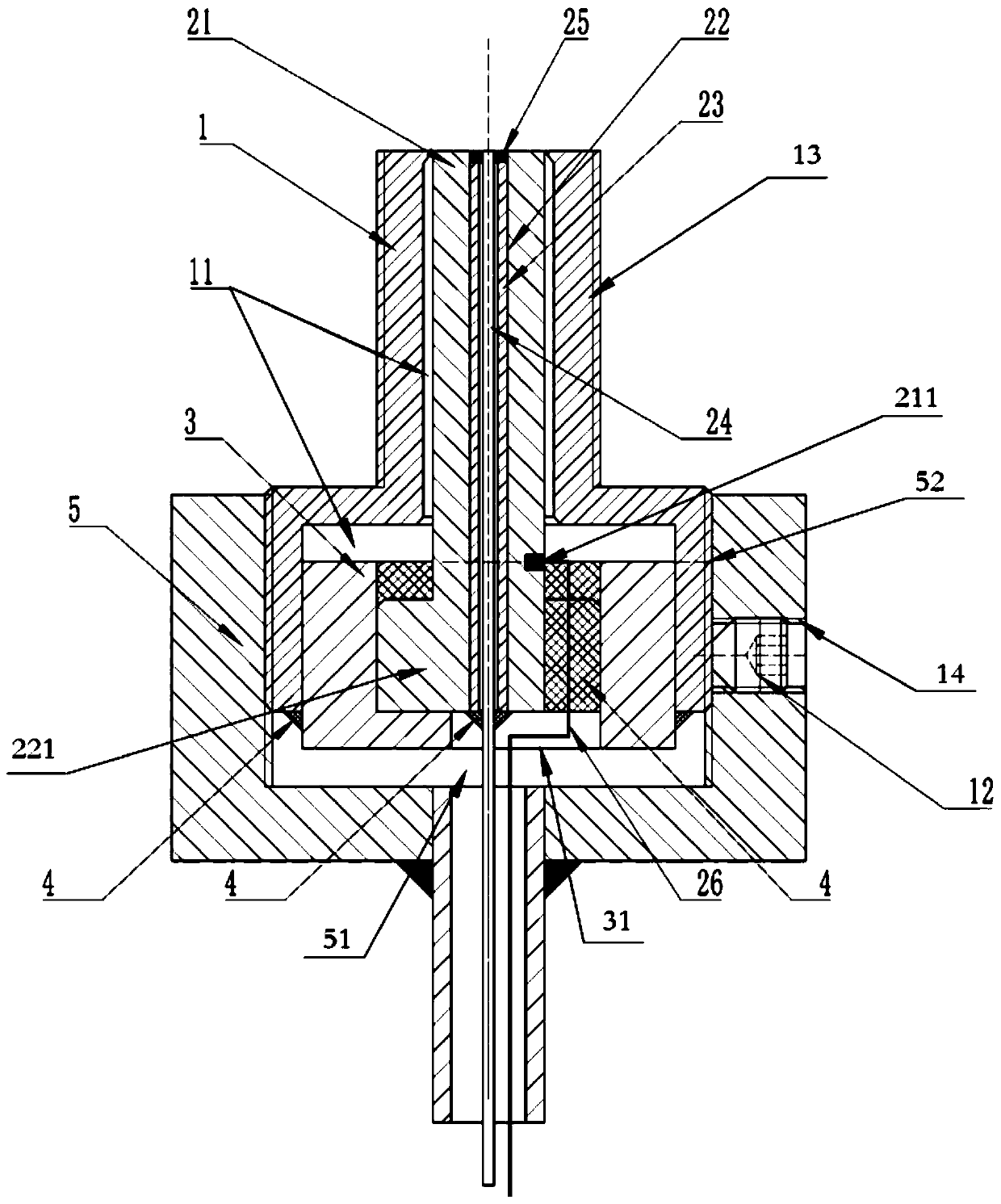

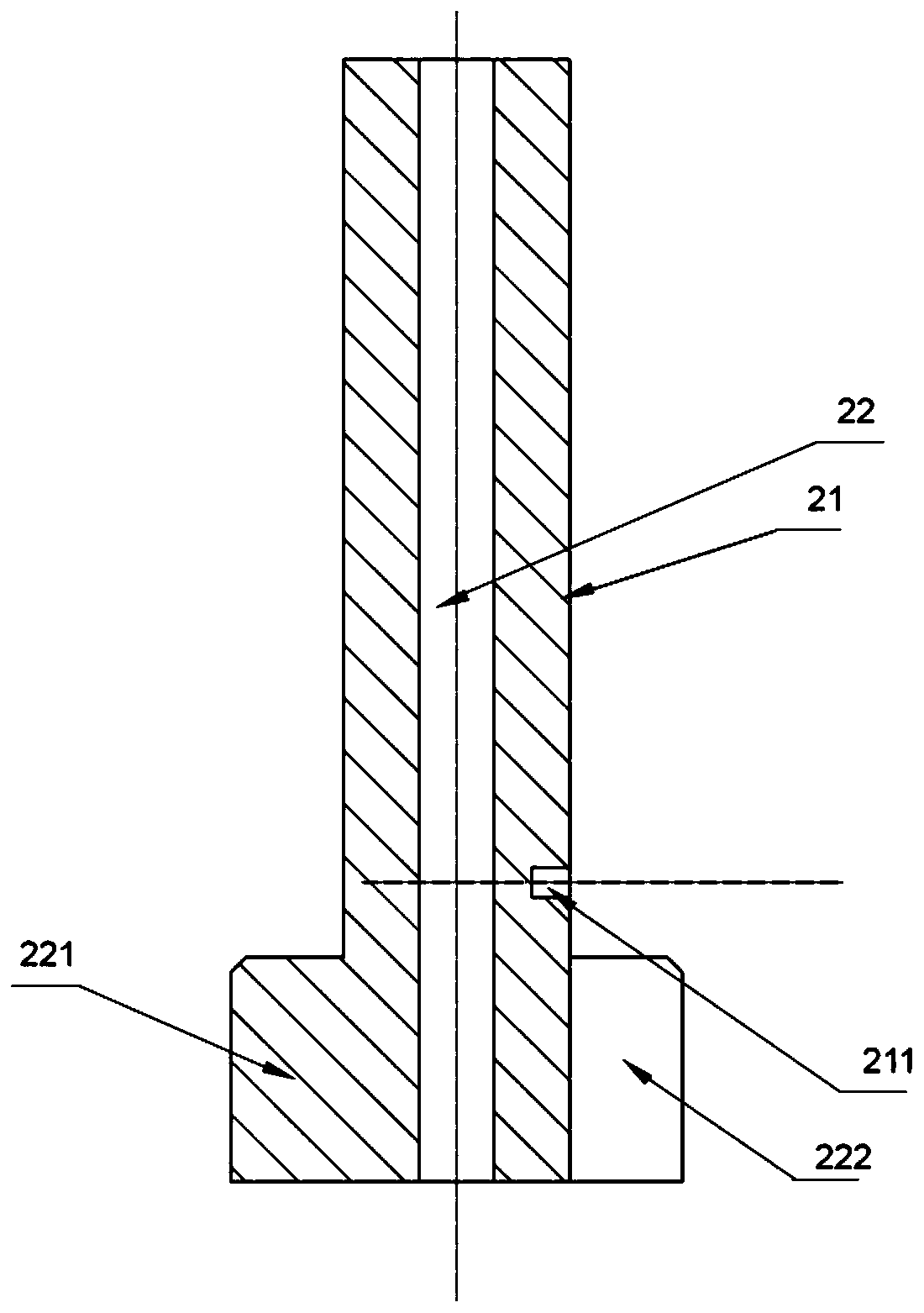

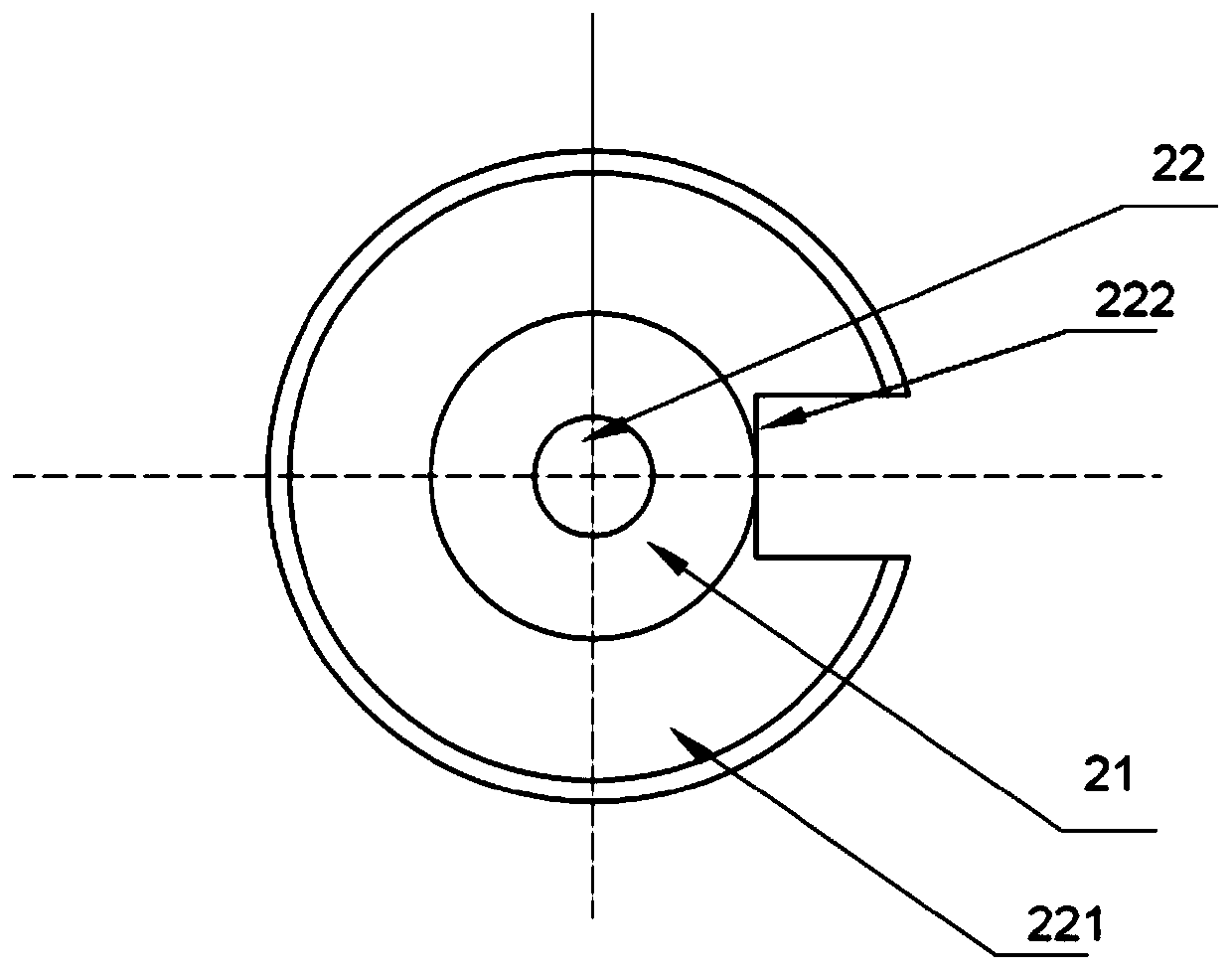

Dynamic heat flow sensor integrating thermoelectric potential effect

PendingCN110388991ASimple processing technologySimplify the assembly processThermometer detailsThermometers using electric/magnetic elementsSilicon alloyChromium nickel

The invention discloses a dynamic heat flow sensor integrating thermoelectric potential effect, which comprises a T-shaped encapsulation outer shell, a nichrome heat transmission body, a corundum tube, an end-exposed single core nickel-silicon alloy wire, and a sterling silver plunger; a T-shaped tail heat sink body is connected on the T-shaped encapsulation outer shell; a containing through cavity is arranged in each of the T-shaped encapsulation outer shell and the T-shaped tail heat sink body; the nichrome heat transmission body is located in the containing through cavity; one end of the nichrome heat transmission body is connected with a phlogopite insulation sleeve; a containing through hole is arranged in the nichrome heat transmission body; the corundum tube is fixed in the containing through hole; the end-exposed single core nickel-silicon alloy wire is fixed in the corundum tube; the end face of the end-exposed single core nickel-silicon alloy wire is leveled with the front end face of the nichrome heat transmission body; and, the sterling silver plunger is located at the outlet position of the containing through hole and connected with the head of the end-exposed single core nickel-silicon alloy wire. The dynamic heat flow sensor integrating thermoelectric potential effect is simple in processing and assembling technology, low in production cost and easy in quality control, and is advantaged in improving the thermal response speed of the sensor and the test precision and prolonging the effective test time.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

High-damping Ag-Li-Sn silver-lithium alloy with electric conductivity close to that of pure silver

InactiveCN107858547AAvoid burnsPrevent excessive evaporationMetal/alloy conductorsLithiumChemical composition

The invention discloses a high-damping Ag-Li-Sn silver-lithium alloy with electrical conductivity close to that of pure silver. In terms of weight percentage, the chemical composition of the alloy is: Li:0.5‑3.4wt.%, Sn:2.6‑3.8wt.%, Be:0.2‑0.5wt.%, Hf:0.1‑0.3wt.%, Sr:0.5‑ 0.8wt.%, Ge: 0.2‑0.4wt.%, In: 0.1‑0.3wt.%, Ta: 0.1‑0.3wt.%, Gd: 0.2‑0.3wt.%, B: 0.2‑0.4wt.%, The balance is silver. Compared with traditional electrical contact silver alloys, the material has excellent mechanical properties, high electrical conductivity and excellent damping properties.

Owner:GUANGZHOU YUZHI TECH CO LTD

A kind of antioxidant silver and preparation method

ActiveCN110158064BImprove connection tightnessImprove antioxidant capacityLiquid/solution decomposition chemical coatingWeather resistanceSterling silver

The invention belongs to an anti-oxidation material, in particular to an anti-oxidation silver and a preparation method, comprising silver, the surface of the silver is covered with an anti-oxidation film, and the anti-oxidation film includes the following components in parts by weight: silicon dioxide 45-60 parts, boron oxide 5-10 parts, zinc oxide 5-15 parts, potassium oxide 20-30 parts. The film is nano-scale, dense and transparent, uniform and continuous, does not affect the appearance and feel of pure silver, and has anti-oxidation, high temperature resistance, and good weather resistance, effectively solving the problem of easy oxidation and discoloration of pure silver.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

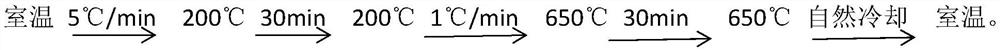

Preparation method of silver graphite electrical contact with continuous pure silver layer on side

ActiveCN113284767BStrong resistance to fusion weldingSmall amount of deformationElectric switchesEmergency protective device manufactureSterling silverGraphite

The invention discloses a method for preparing a silver-graphite electric contact with a continuous pure silver layer on the side, and the technical scheme includes the following steps: (1) powder mixing, uniformly mixing silver powder and graphite powder; (2) preliminary pressing; (3) ) sintering, sintering the compact under a reducing atmosphere; (4) repressing, repressing the sintered compact; (5) heating the recompact in compressed air for decarburization; (6) cutting or milling processing, the silver-graphite base after decarburization is divided into two, obtains two contacts; perhaps milling off one side silver layer, obtains single contact; (7) cleaning, will pass through step ( 6) The obtained contacts are subjected to grinding, polishing and drying treatment to obtain finished products. The silver-graphite electrical contact prepared by the invention has graphite distributed in any structure, and the contact has strong welding resistance; the side has a continuous pure silver layer, and the contact has a long mechanical life.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

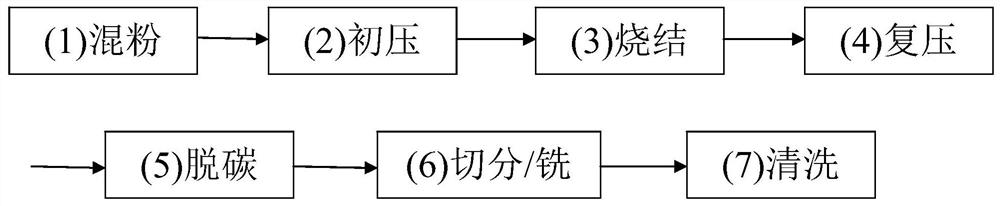

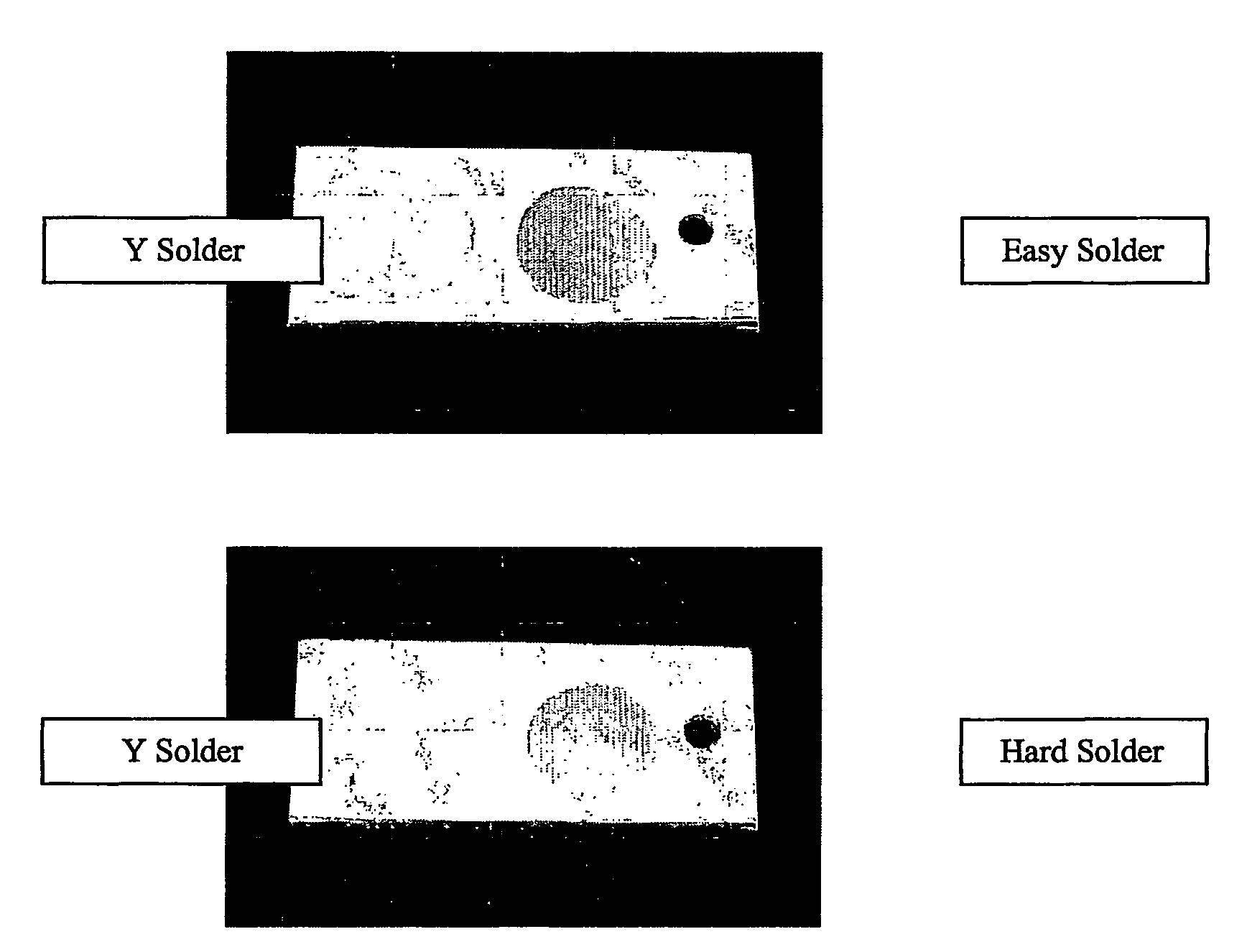

Silver solder or brazing alloys, and their use

InactiveUS20070144624A1Low melting pointImprove liquidityWelding/cutting media/materialsSoldering mediaSterling silverBraze alloy

The present invention relates to silver solder or brazing alloys and to their use in making soldered joints in various grades of silver, particularly silversmithing grades. They alloys are of the Ag-Cu-Zn family containing at least 55 wt % Ag and from 0.5 to 3 wt % Ge. Additional alloys are silver solders or brazing alloys of the Ag-Cu-Zn family containing more than 70 wt % Ag and from 0.5 to 3 wt % Ge. They can exhibit an advantageous combination of colour, flowability and corrosion resistance. A method is also provided of making a joint in Sterling silver which includes using a silver solder or brazing alloy of the Ag-Cu-Zn family containing 10-30 wt % Cu, 8-15 wt % Zn, from 0.5-3 wt % Ge, optionally 0.05-0.4 wt % Si, optionally 1-3 wt % Sn, optionally 1 ppm-0.3 wt % B, the balance being 55-77 wt %, Ag, said solder being a colour match for said Sterling silver.

Owner:MIDDLESEX SILVER CO LTD

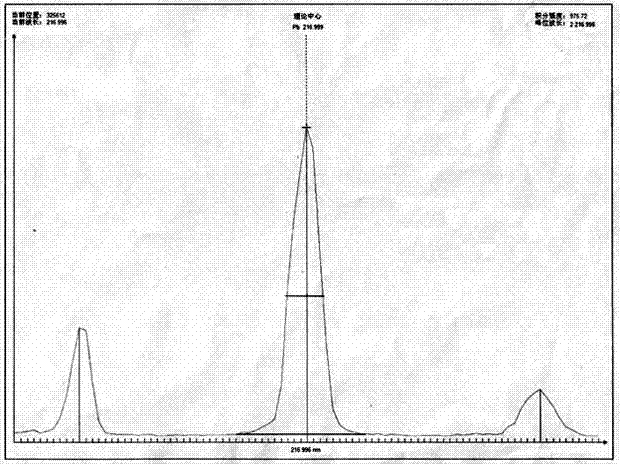

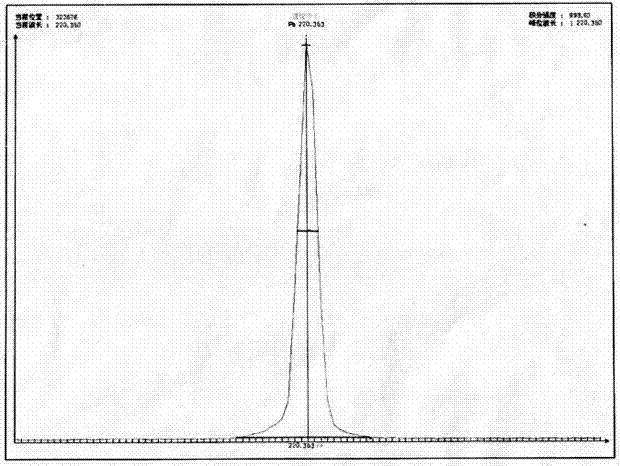

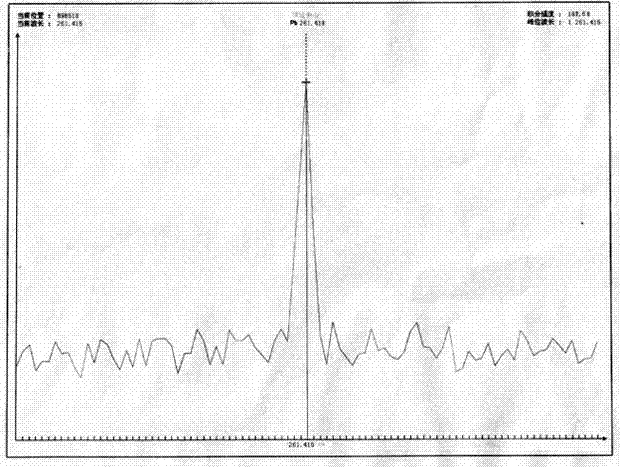

Method for detecting lead content in submicron silver powder prepared through PVD method by using ICP

ActiveCN102346149AAccurate detectionLow costPreparing sample for investigationAnalysis by thermal excitationOptical spectrometerSterling silver

The invention discloses a method for detecting a lead content in submicron silver powder prepared through a PVD method by using ICP. The method comprises the following steps: (1) preparing submicron silver powder; respectively adding standard sterling silver or the silver powder sample to nitric acid according to a certain ratio, then carrying out mixing and heating to completely dissolve the silver, wherein 1 g of the standard sterling silver or the silver powder is added to 10-30 mL of the nitric acid; (2) cooling the two resulting solutions and respectively carrying out metered volume; (3) drawing standard curves of different lead spectrum lines in the silver solution, wherein the standard curve is drawn through the following steps that: a lead standard solution with a concentration of 0.00 mug / mL and a lead standard solution with a concentration of 10.00 mug / mL are adopted, the spectrum line intensity of the lead is determined under working conditions set through an inductively coupled plasma spectrometer, the lead concentration is adopted as the abscissa, the spectrum line intensity is adopted as the ordinate; (4) selecting the optimal spectrum line; (5) determining the spectrum line intensity in the silver powder solution, and the corresponding lead content, then calculating the lead content in the silver powder. The method provided by the present invention has the following advantages that: the spectrum line is easy to find; the detection cost is low; the method is applicable for the practical detection in the factory.

Owner:JIANGSU BOQIAN NEW MATERIALS

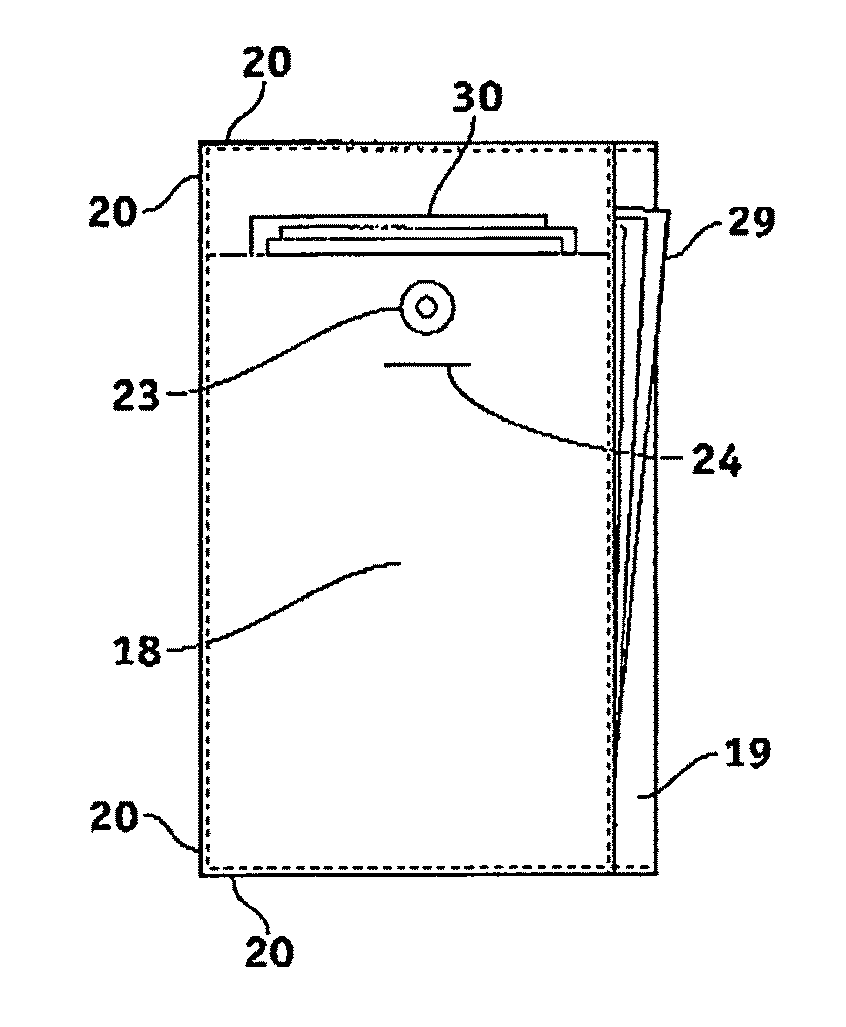

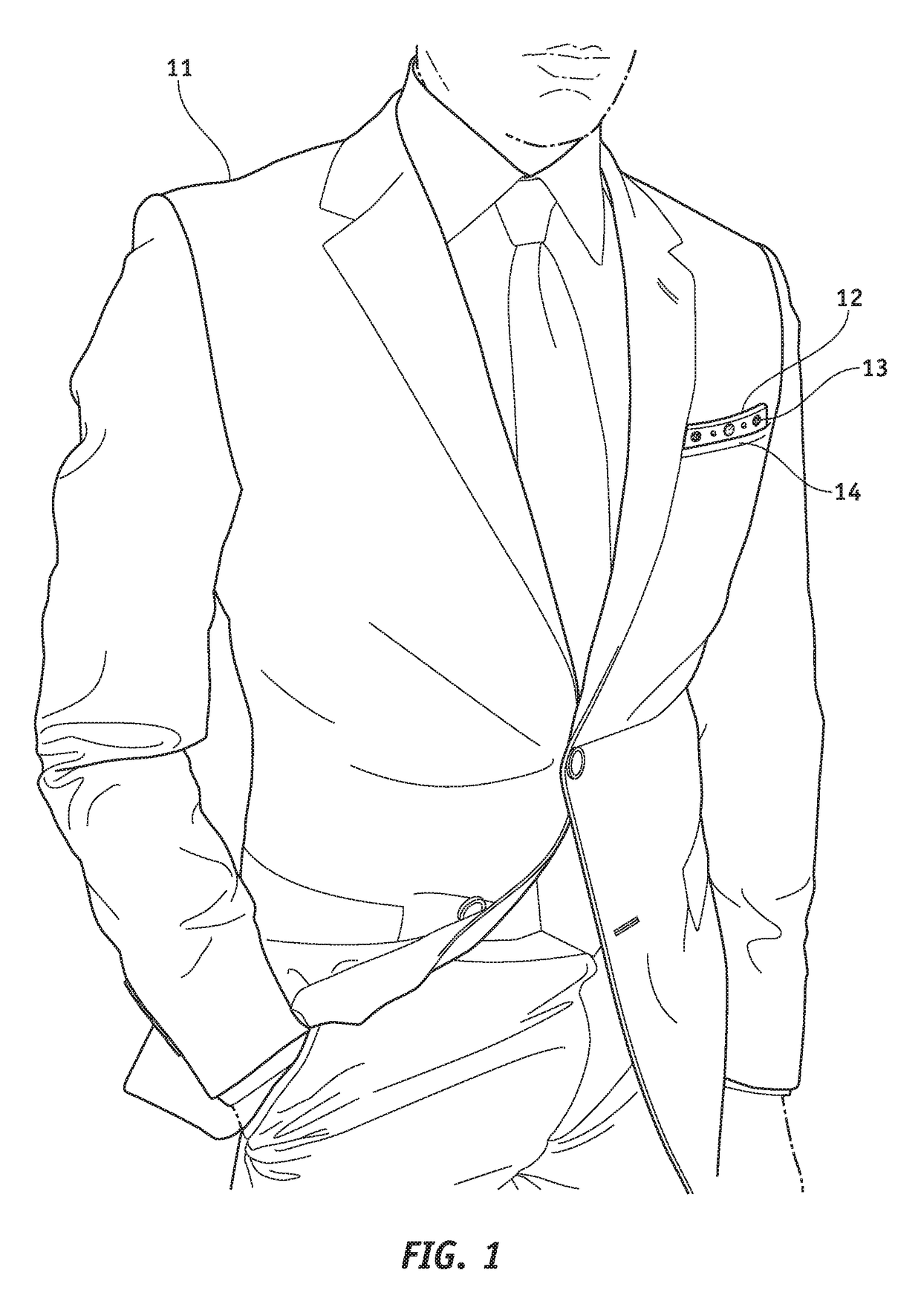

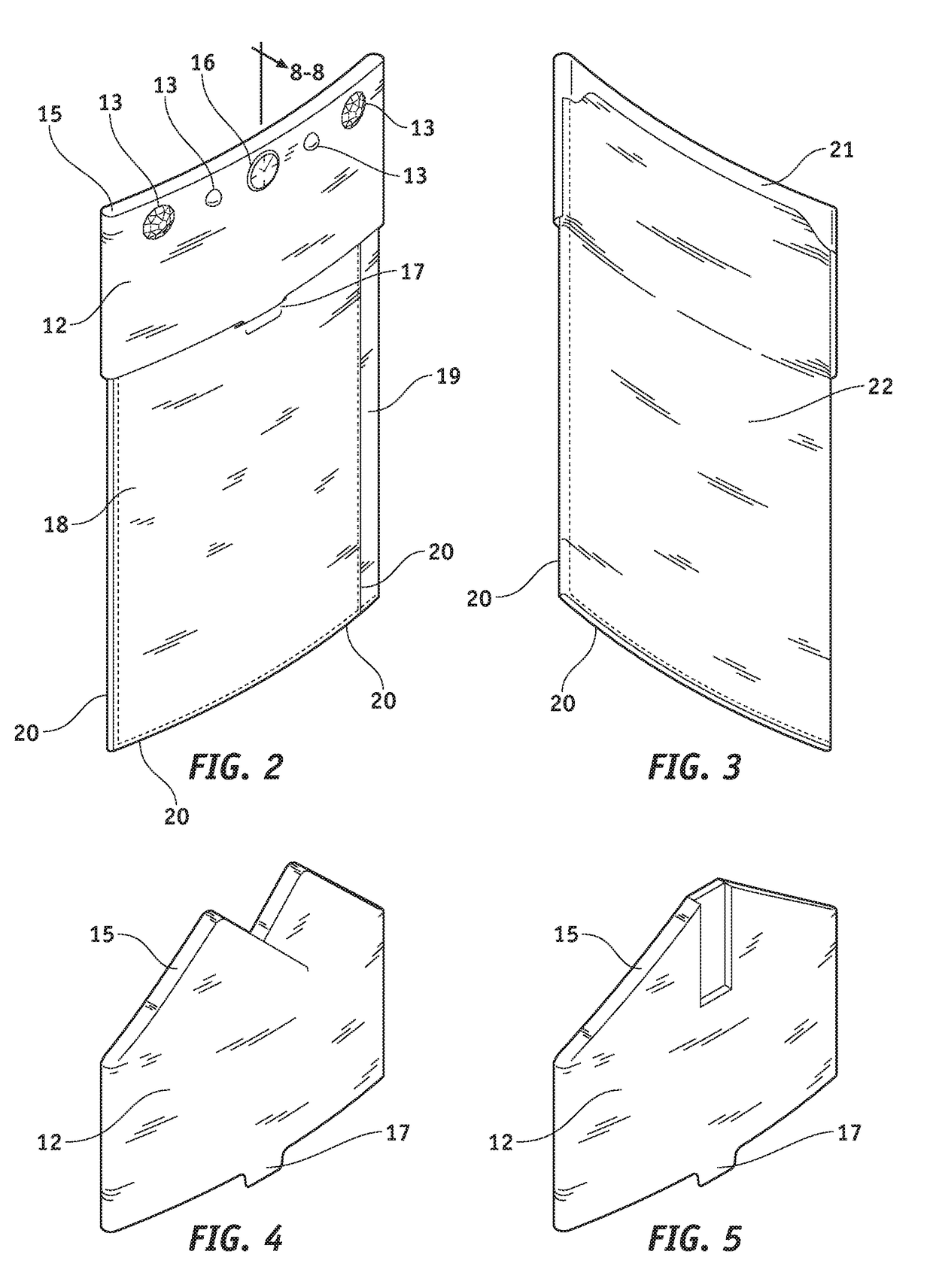

Pocket square jeweled cap and base

The Pocket Square Jeweled Cap And Base is an article of jewelry comprised substantially of a thin cap made of or plated with semi precious or precious metal, enamel, wood, crystal, sterling silver stained glass, gold, platinum, ebony, pearls or ceramic. Inside the metal cap is substantially a metal male protruding nub snap component. Affixed to the caps are substantially semi precious or precious stones, optional small time piece, enamel, wood, crystal, sterling silver, stained glass, gold, platinum, ebony or ceramic. Inserted into and snapped to the bottom opening of the decorated cap is a thin, brittle, flexible, elongated rectangular, pocketed or un pocketed triple stitched base component. Affixed to the upper base component is a male metal protruding nub snap which is then attached, snapped to the inside of the caps metal female snap receptacle creating a single ornament. The ornament is inserted into a coat outer breast pocket exposing one third to one fourth of the upper decorated metal cap above the top edge of the pocket.

Owner:ROEDER SR STEVEN PAUL

Purple gold Jian ware with silver pekoe

The invention relates to a purple gold Jian ware with silver pekoe. Specifically, the invention provides a preparation process of a purple gold Jian ware with silver pekoe. The process comprises the following steps: glazing a green body, and roasting the glazed green body to obtain the purple gold, silver and millipekoe Jian ware. The glaze surface of the purple gold Jian ware with silver pekoe is densely covered with silver pekoe lines which are moist, dense, clear and uniform, are as beautiful as jade, present a strong layering sense and belong to top-level pekoe lines; beautiful and glittering purple gold stripes are arranged among the silver pekoe lines, and the purple gold stripes are spread like broken gold, rich in color and prominent in embossment sense; and the glaze surface is glittering, beautiful and unsophisticated in the sun, presents good texture and prominent three-dimensional sensation, and thus has graceful appearance and high artistic and collection value.

Owner:南平市建阳区水吉后井成义建盏文化推广有限公司

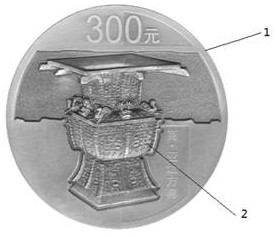

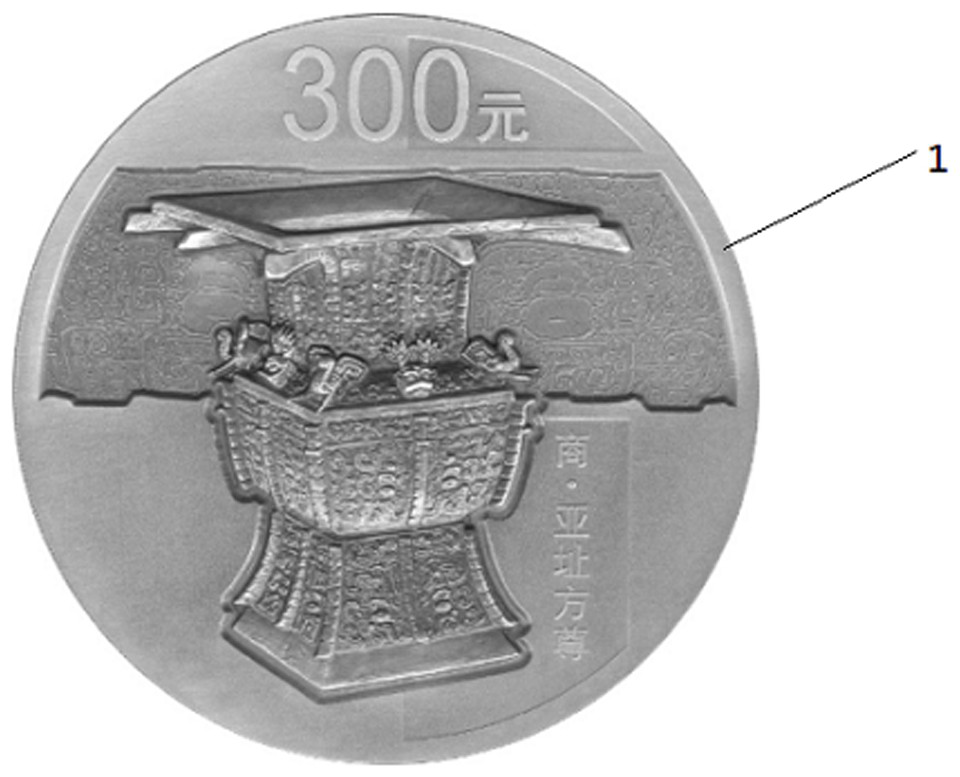

A process for partial coloring of sterling silver commemorative coins/chaps

ActiveCN107630214BEvenly distributedImprove bindingMetallic material coating processesLocal colorSterling silver

Owner:SHANGHAI MINT

A preparation method of composite sheathed iron-based superconducting wire

ActiveCN111292899BAvoid lostLow costSuperconductors/hyperconductorsSuperconductor devicesWire rodSterling silver

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

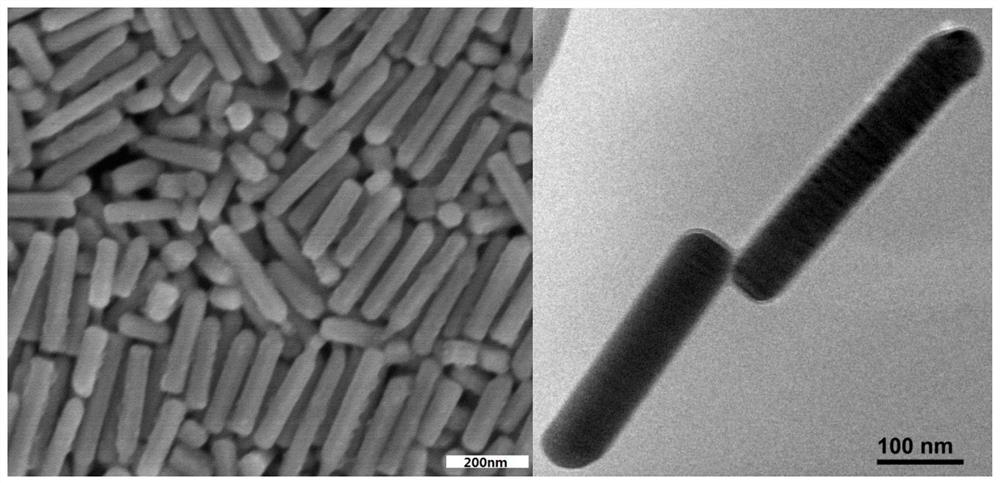

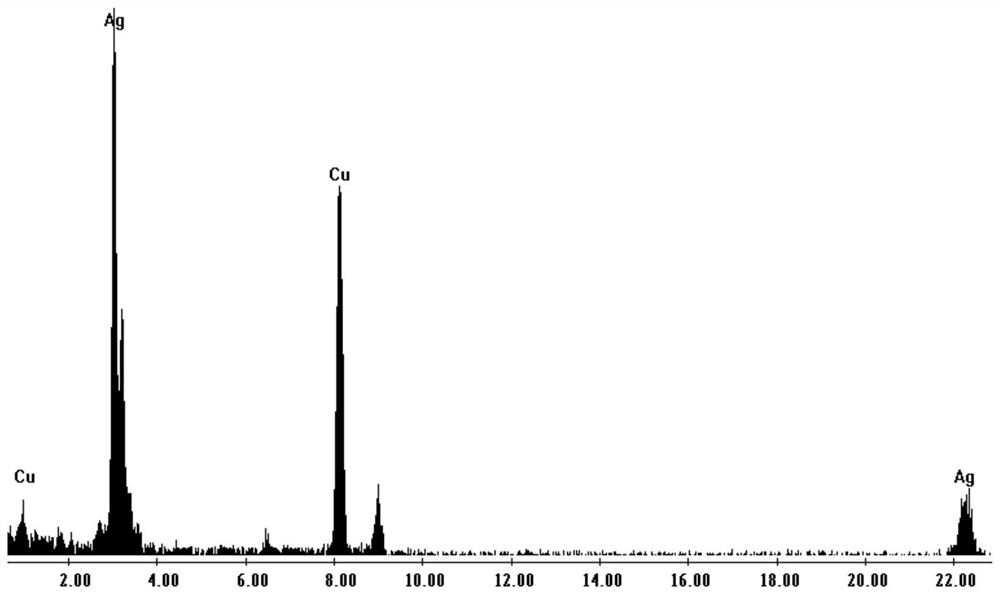

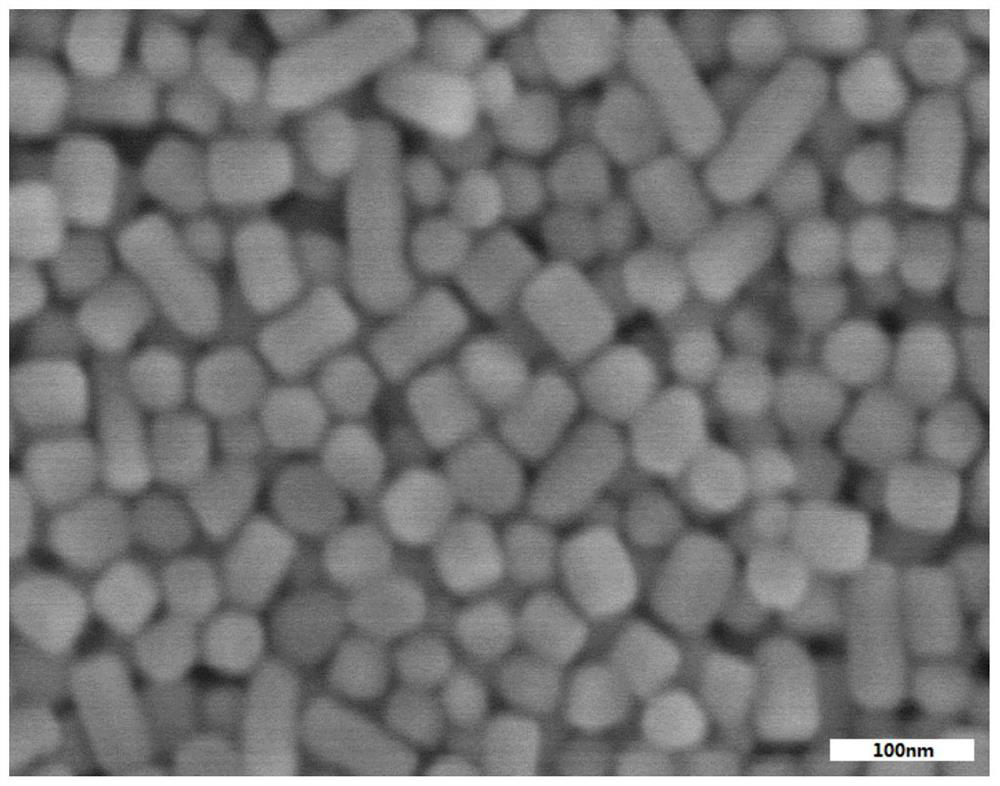

A kind of pure silver nanorod with hexagonal cross section and preparation method thereof

ActiveCN111283214BImprove defectsAvoid lossMaterial nanotechnologyTransportation and packagingNanoparticleSterling silver

Owner:XIAN TECH UNIV

Silver alloy and its manufacturing process and application

The invention belongs to the technical field of silver alloy and specifically discloses a silver alloy and a manufacturing technology thereof. The silver alloy comprises the following components in percentage by weight: 92.5% of silver, 0.1-7.0% of copper, 0.1-1.0% of silicon, 0.1-1.0% of zinc, 0.01-0.5% of titanium, and 0.1-0.3% of aluminum. The preparation technology comprises the following steps: mixing the components of the silver alloy to obtain a mixture; smelting the mixture in a vacuum condition to obtain melt; under the protection of an inert atmosphere, pouring the melt into an alloysheet ingot; and sequentially performing homogenization heat treatment, re-annealing treatment and hardening heat treatment on the alloy sheet ingot, to obtain the silver alloy. The silver alloy disclosed by the invention is at least twice stronger than sterling silver in the ability of resisting vulcanization blackening, and has relatively strong as-cast hardness and high-temperature oxidation resistance and high processability; and moreover, the hardness reaches 150HV or above and reaches the hardness of stainless steel.

Owner:依波精品(深圳)有限公司

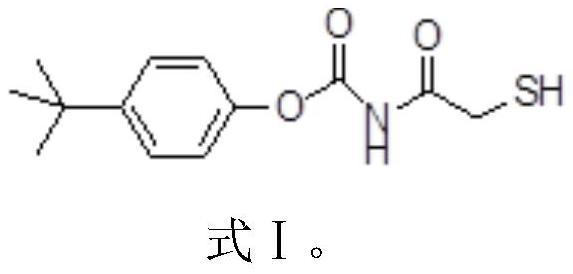

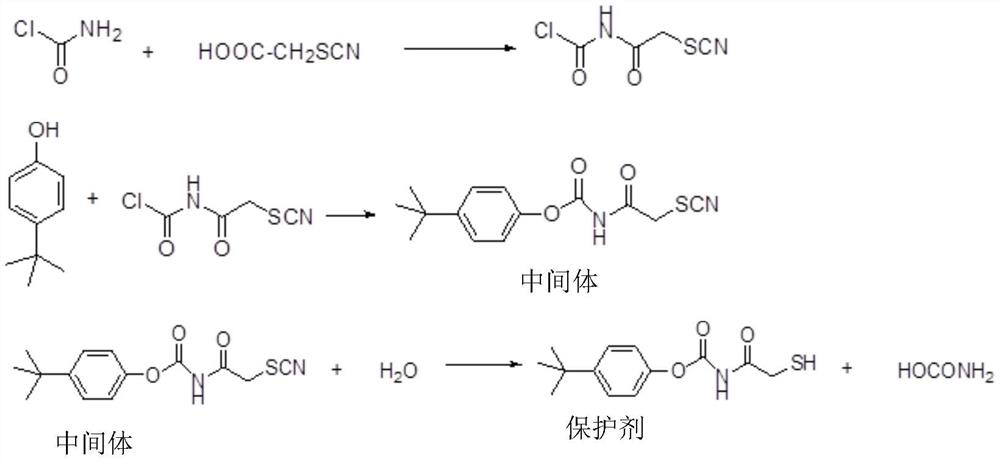

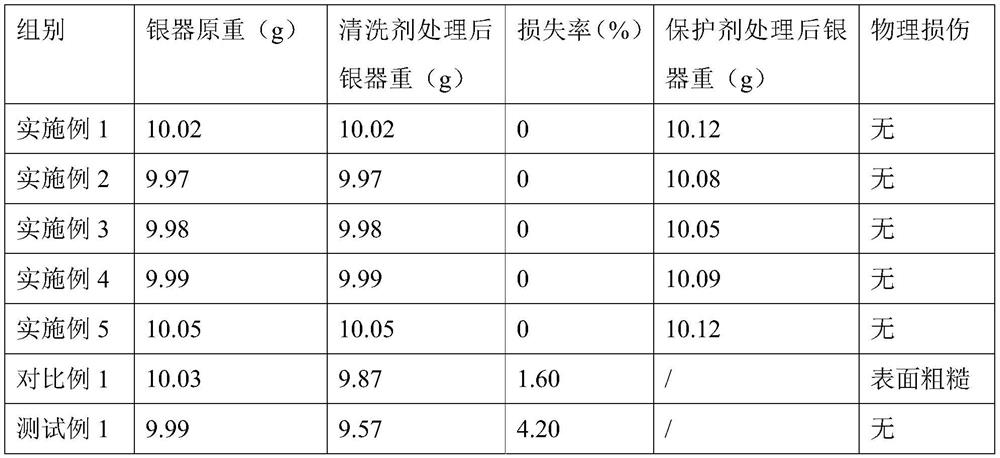

Treatment method for surface discoloration of sterling silver products

ActiveCN110424018BReduce lossesTo achieve the purpose of preventing silver discolorationOrganic chemistryPolyolMedicine

The invention proposes a treatment method for the discoloration of the surface of pure silver products. The pure silver products with discolored surfaces are soaked in a solution prepared with a cleaning agent. After 1-2 hours, the silverware is taken out, cleaned, dried, and soaked in a protective agent. After 30‑50 minutes in the prepared solution, take out the silverware, wash it, and blow it dry. The cleaning agent is prepared from the following raw materials in parts by weight: 10-20 parts of concentrated ammonia water, 3-5 parts of sodium cyanide, 20-30 parts of glucose, 12-17 parts of inorganic alkali and 20-50 parts of polyol; The protective agent has the following structure: the process of the present invention is simple, and the processing time is very short; the normal temperature operation does not cause physical damage to the surface, and the loss of silver is almost zero; the cleaning agent and the protective agent can be stored at room temperature, ready to use, Repeated use, subsequent cleaning is simple, thorough, and low-cost, which is cost-effective compared with other methods.

Owner:上海志行合力网络技术有限公司

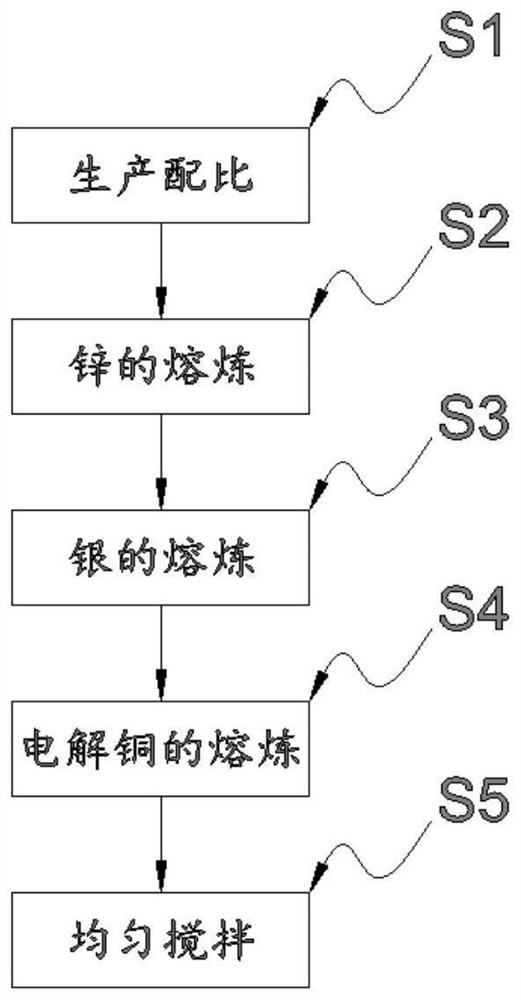

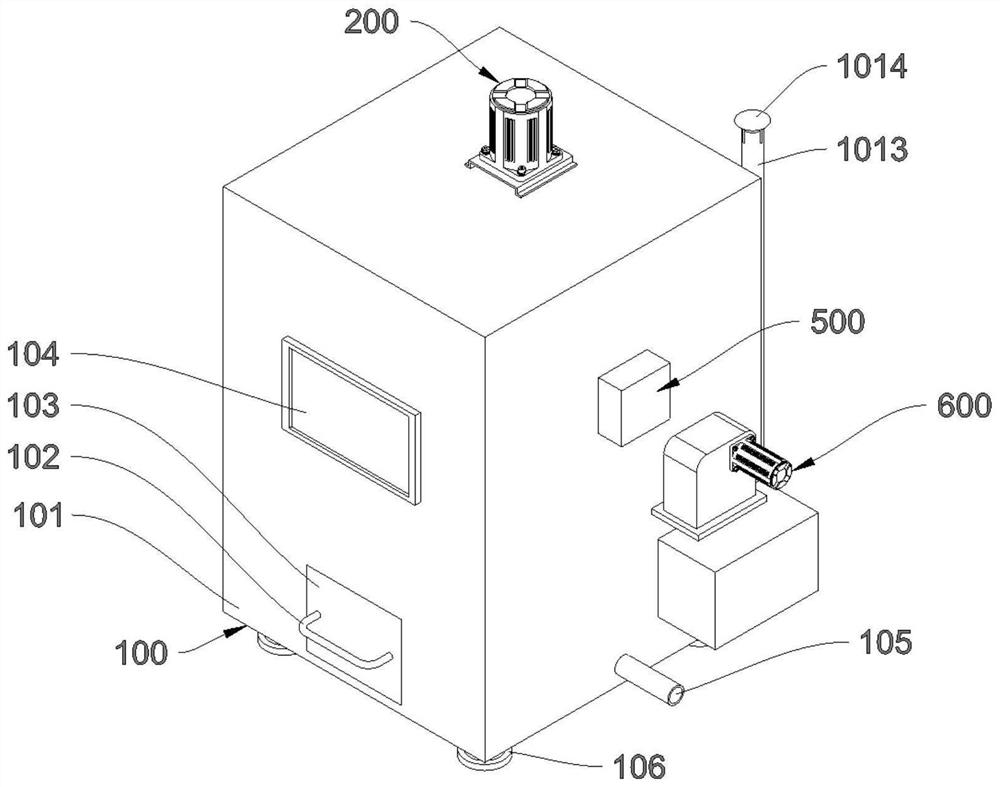

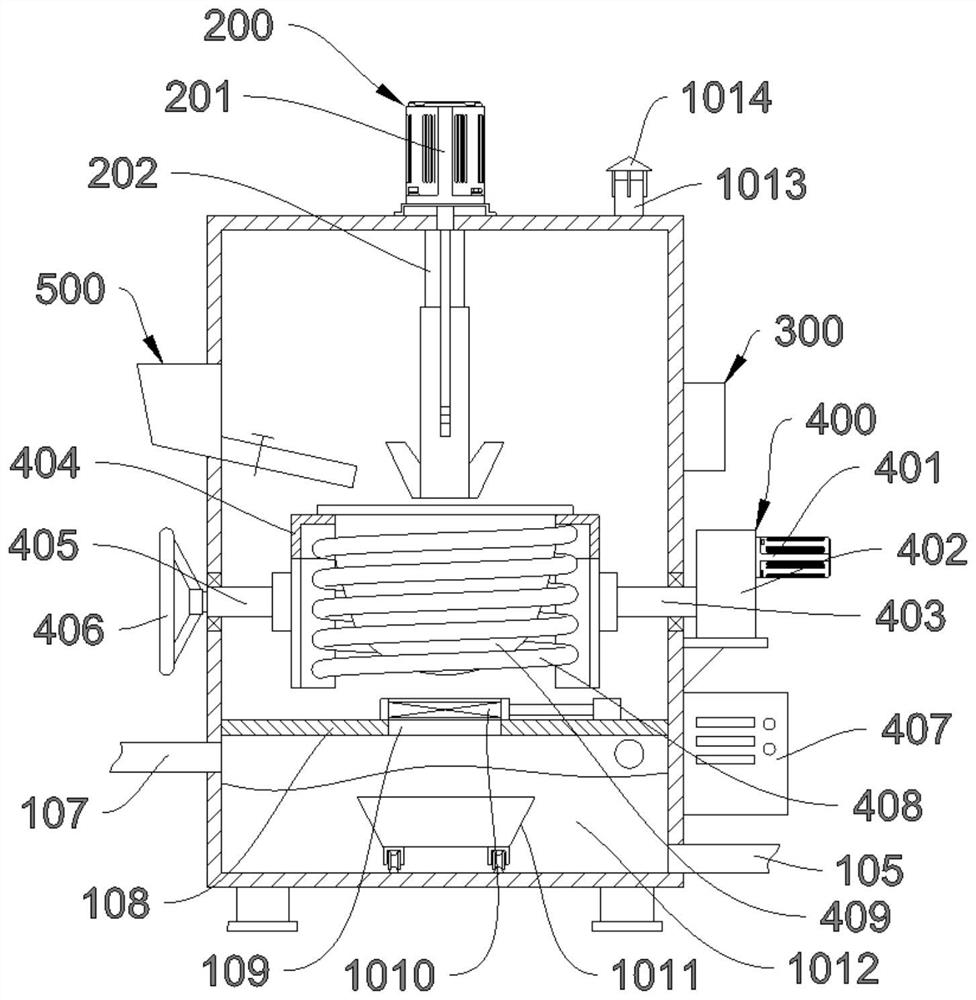

A kind of production process and production equipment of cooked bornite material

ActiveCN113265561BAvoid the risk of accidental injuryProtect life and property safetyStirring devicesCharge treatment typeFurnace temperatureIntermediate frequency

The invention provides a production process and production equipment for cooked spot copper material, comprising the following steps: producing a proportion, proportioning electrolytic copper, pure silver and zinc as synthetic materials for producing cooked spot copper, smelting zinc, First put zinc into the crucible according to the proportion, and raise the furnace temperature to the first specified temperature. The invention provides a production equipment for cooked spot copper material, which includes an equipment main body, the equipment main body includes a casing, and a telescopic stirring device is arranged on the top of the casing. The middle part of the inside of the shell is provided with an intermediate frequency smelting device, and a sealing plate is arranged inside the shell and near the bottom of the intermediate frequency smelting device. The invention uses the telescopic stirring device to stir, so as to complete the production work with high quality and complete automatic production, replacing the previous traditional The manual craftsmanship effectively improves the production efficiency and product quality. At the same time, the replacement of labor by machines also avoids the risk of accidental injury to traditional manual laborers, and protects the safety of workers' lives and property from loss.

Owner:云南滇工李雕塑艺术有限公司

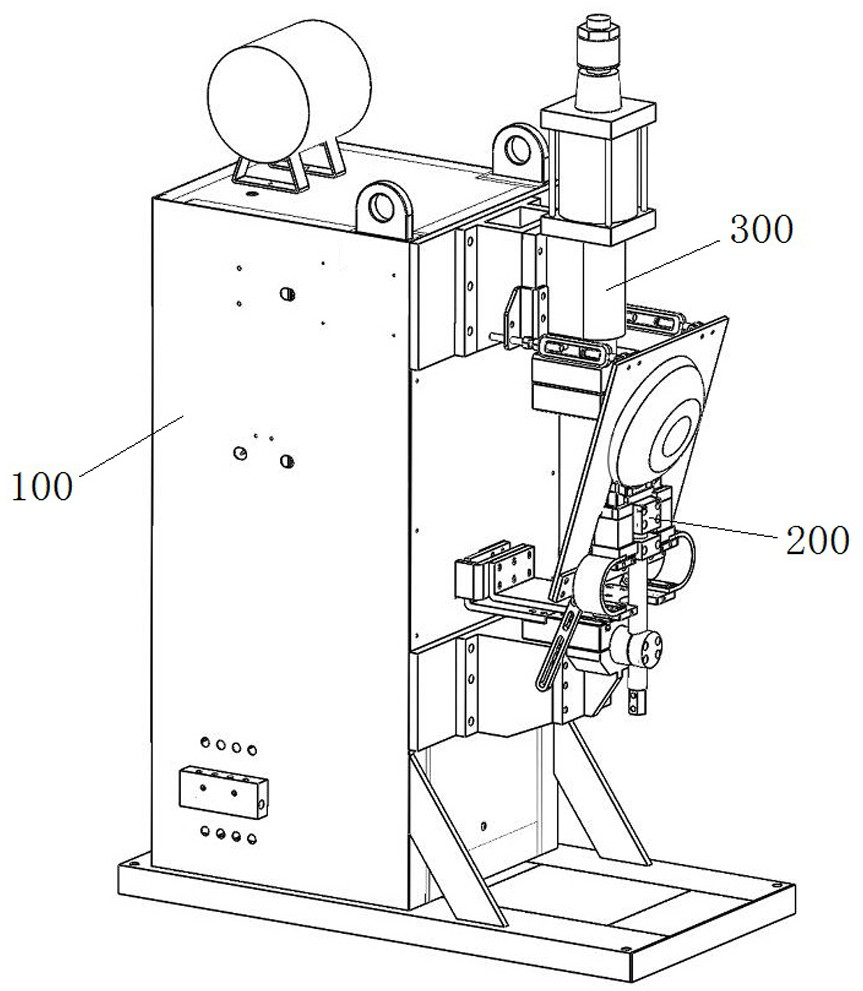

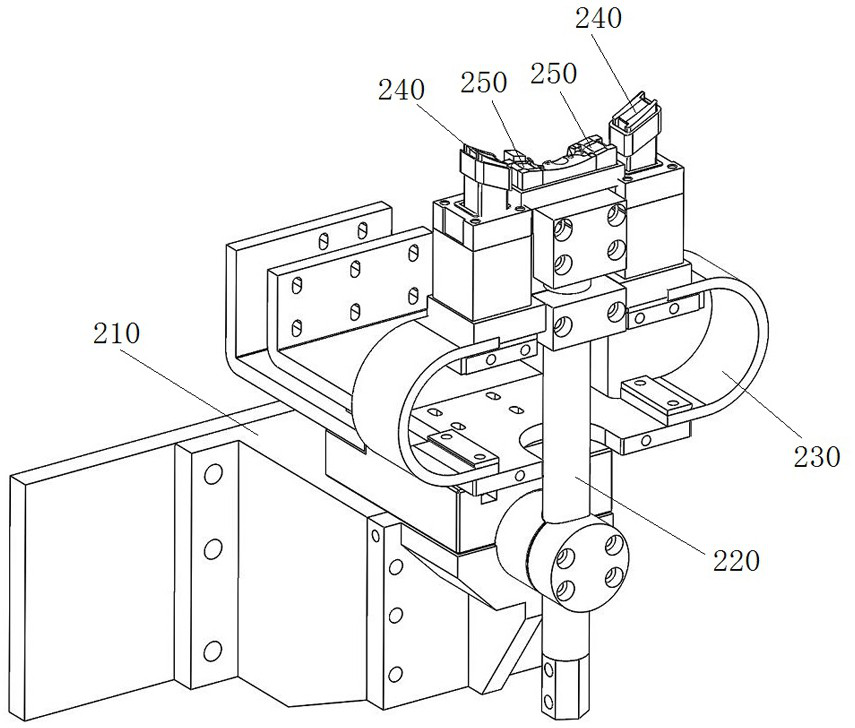

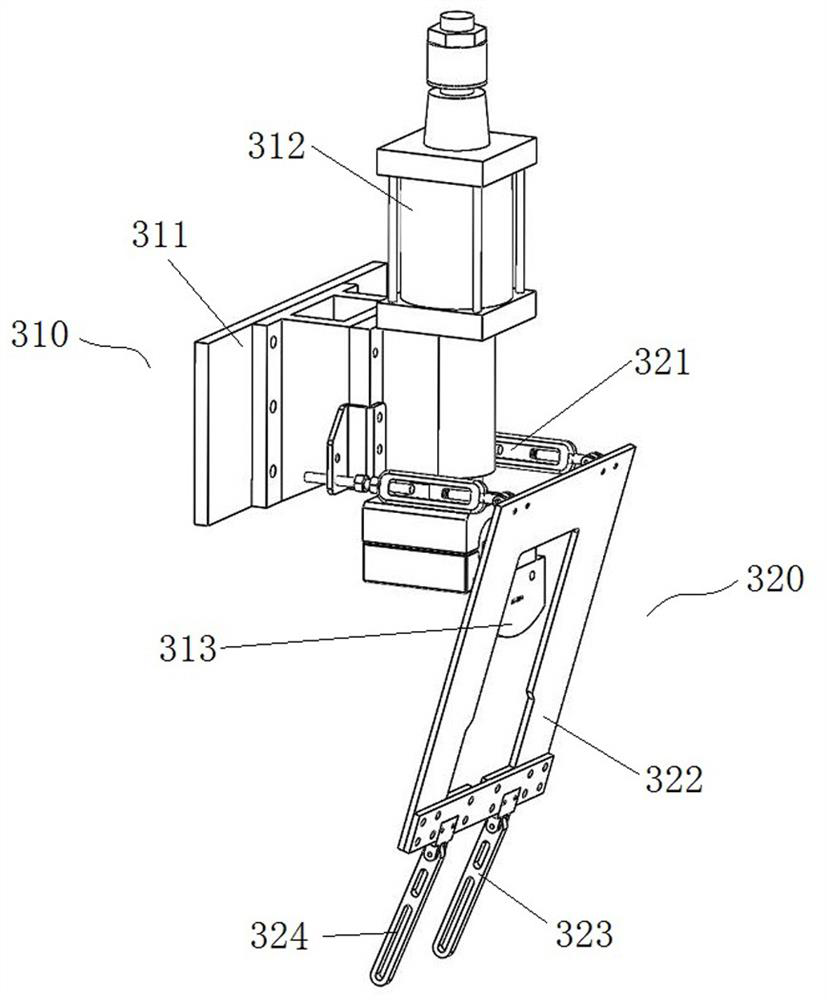

A single-sided double-point traceless welding tool and welding process

ActiveCN112719549BSimple structureEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesSterling silverStructural engineering

Owner:HUIZHOU YILONG MACHINERY & EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com