Method for detecting lead content in submicron silver powder prepared through PVD method by using ICP

A sub-micron level, lead content technology, applied in the field of ion emission spectrometer (Ion Emission Spectrometer) detection, can solve the problems of unfavorable factory production detection, difficulty in finding spectral lines, high detection cost, etc., and achieve the effect of reducing detection input cost, reducing cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Standard sterling silver: use national standard reagents, manufacturer: Tianjin Guangfu Fine Chemical Research Institute, purity 99.99%;

[0049] 2. Using PVD method (conventional method) to make sub-micron silver powder;

[0050] 3 Draw a calibration curve for calibration lead;

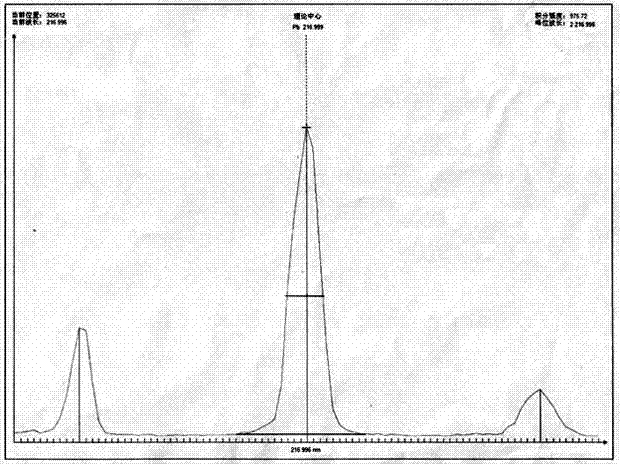

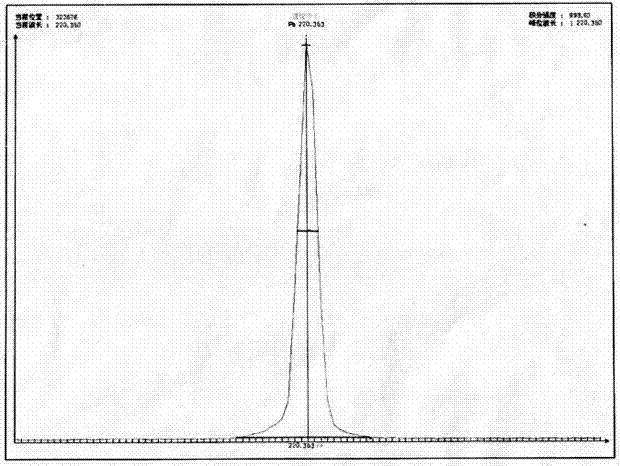

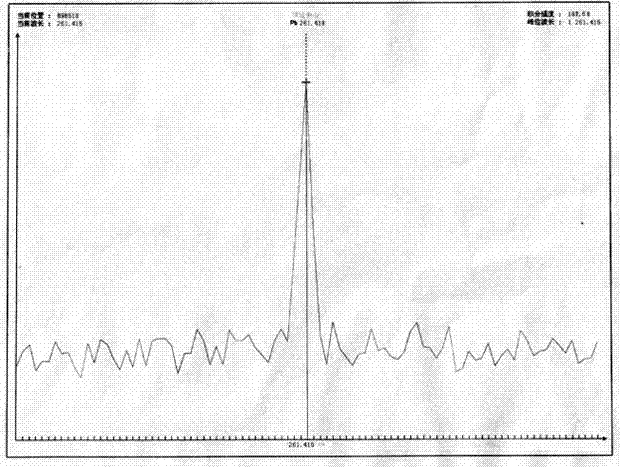

[0051] Use the standard solution, under specified working conditions, measure under four kinds of spectral lines respectively, the integral spectral line of lead is drawn automatically by computer, see Figure 1~4 .

[0052] 4 Comparative analysis and screening of calibration curve results

[0053] The results are shown in Table 1.

[0054] Table 1 Parameters for drawing standard curve

[0055]

[0056] Result analysis, can compare and draw from the SNR S data: the SNR under this spectral line of 220.353nm is 10.065, and this SNR S is the strongest, namely in the present invention detects silver in silver by ICP-AES The spectral line 220.353nm is the best in the content of lead.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com