A kind of production process and production equipment of cooked bornite material

A production process and cooked spot technology, applied in the production process and production equipment field of cooked spotted copper materials, can solve the problems of many processes, limited production quality control level, too high product price, etc., so as to improve production efficiency and product quality, The effect of protecting the safety of workers' lives and property and protecting them from loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

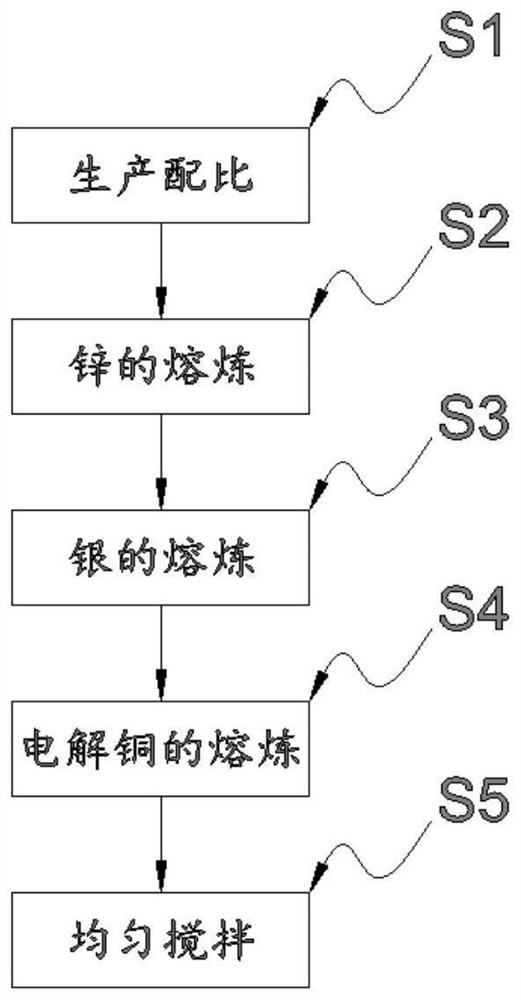

[0037] see figure 1 , the present invention design provides a kind of production technology of cooked bornite material, comprises the following steps:

[0038] S1, production ratio, electrolytic copper, pure silver and zinc are used as synthetic materials for producing cooked bornite according to a certain ratio;

[0039] S2, zinc smelting, put zinc into the crucible first according to the proportion, raise the furnace temperature to the first specified temperature, at this time, the zinc reaches the melting point and melts into a liquid state, and keeps the liquid state stable for a period of time;

[0040] S3, silver smelting, put pure silver into the crucible that has melted liquid zinc in proportion, raise the furnace temperature to the second specified temperature, at this time, the silver reaches the melting point and melts into a liquid state, and keeps the liquid state stable for a period of time;

[0041] S4, smelting of electrolytic copper, put the electrolytic copp...

Embodiment 2

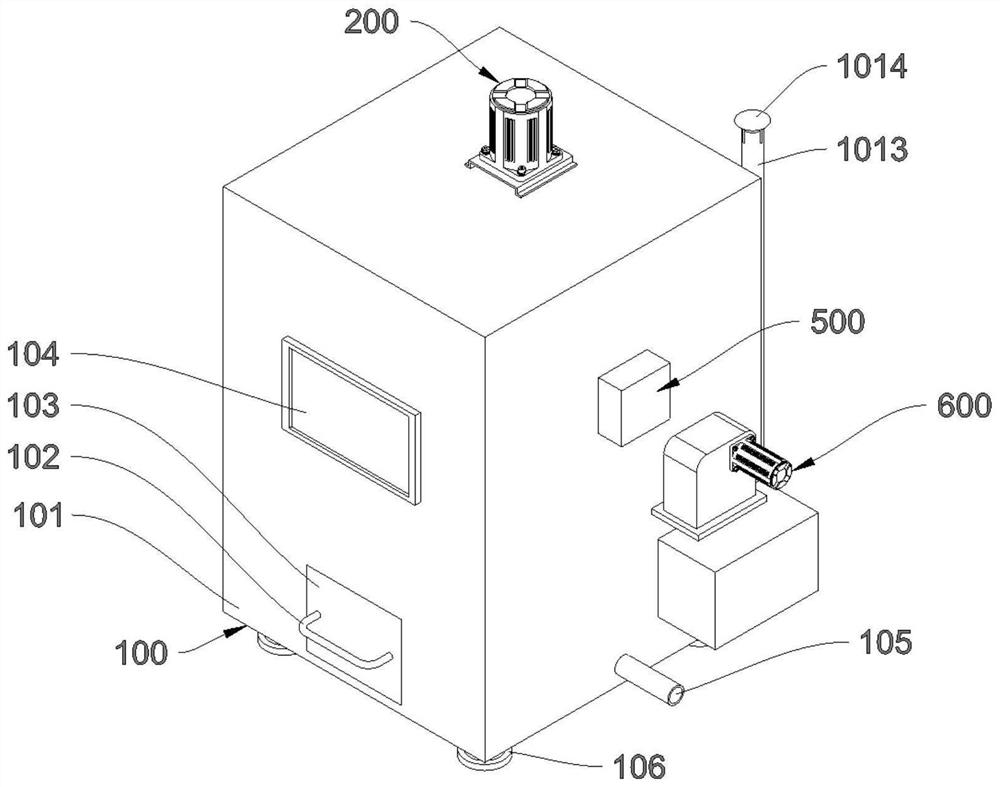

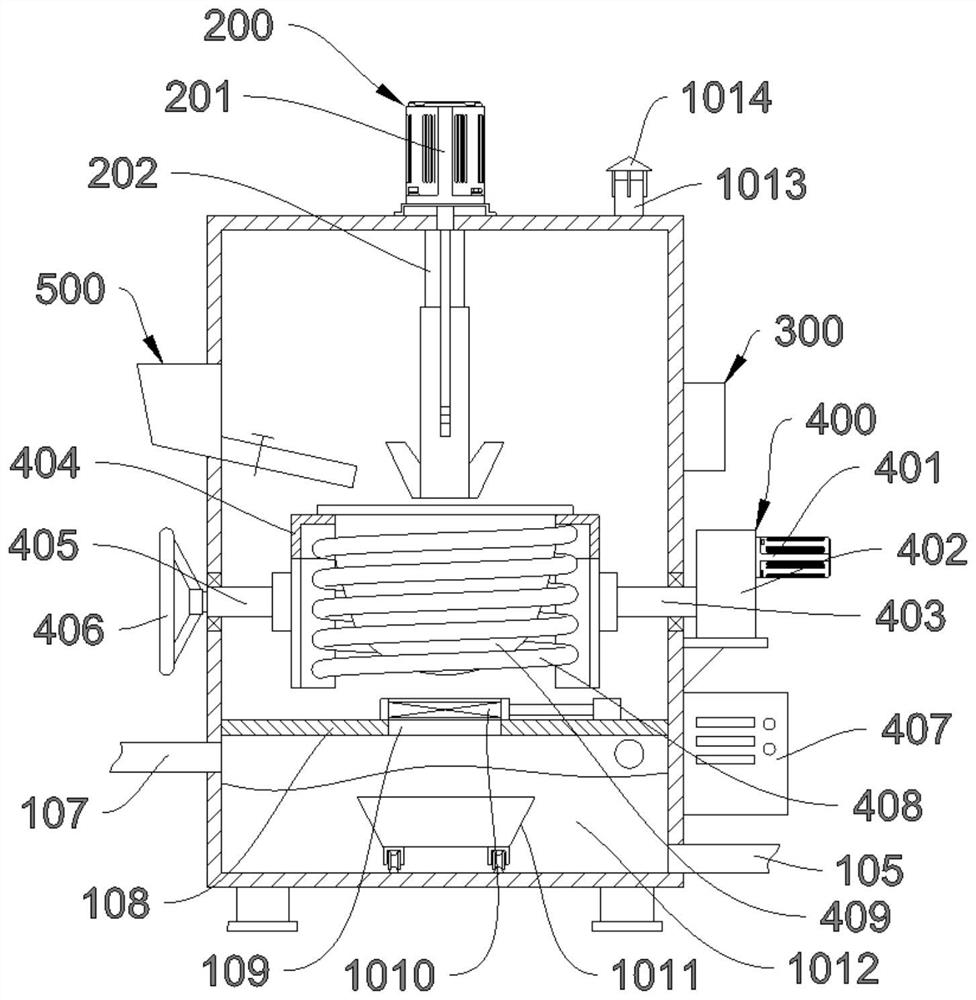

[0047] Please refer to Figure 2-7 , the present invention provides a kind of production equipment of cooked bornite material, comprising equipment main body 100, equipment main body 100 comprises shell 101, the top of shell 101 is provided with telescopic stirring device 200, the middle part inside shell 101 is provided with intermediate frequency smelting device 400, Inside the shell 101 and near the bottom of the intermediate frequency melting device 400, a sealing plate 108 is provided. The sealing plate 108 divides the inside of the shell 101 into upper and lower parts. The surface of the sealing plate 108 is provided with a discharge hole 109. The top of the sealing plate 108 corresponds to An electromagnetic guillotine valve 1010 is fixedly installed at the position of the discharge hole 109, and the lower area of the casing 101 is used as a cooling area 1012 for cooling the cooked spot copper ingot. Pipe 105, the back side of the inner wall of the cooling zone 1012 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com