Automatic positioning group in winder for plastic film

A technology of automatic positioning and plastic film, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc., and can solve problems such as positioning errors and time waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

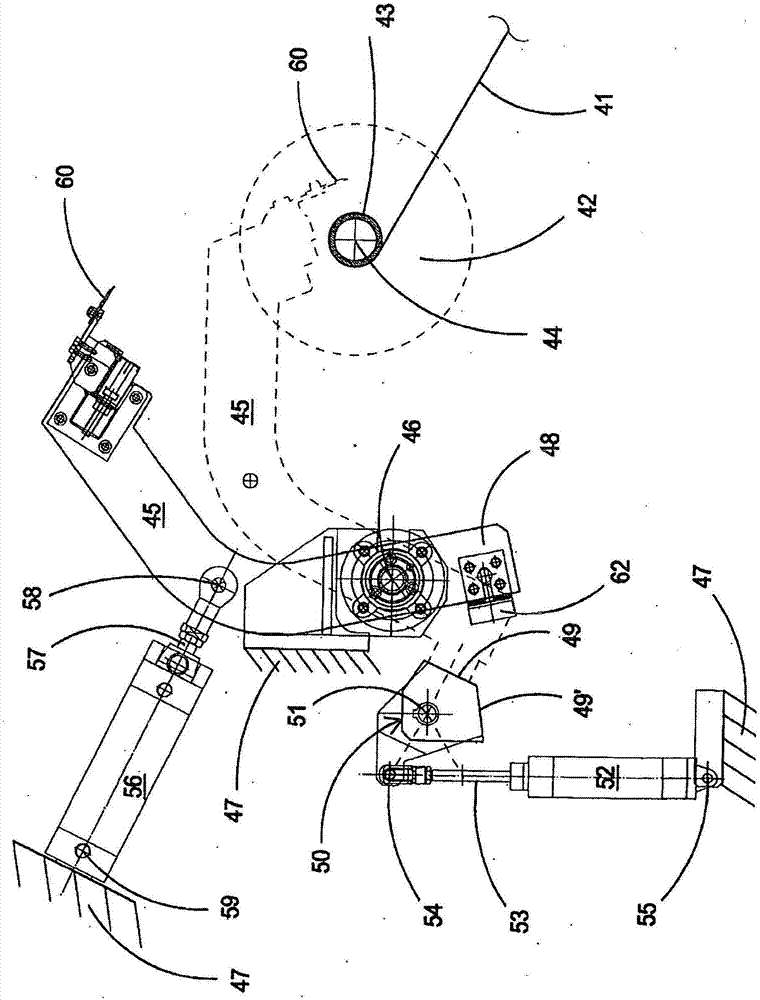

[0031] In the illustrated embodiment, the possibility of operating under two different conditions is assumed for each of the automatic positioning groups shown, but alternatively and almost similarly, more than two positions are also possible.

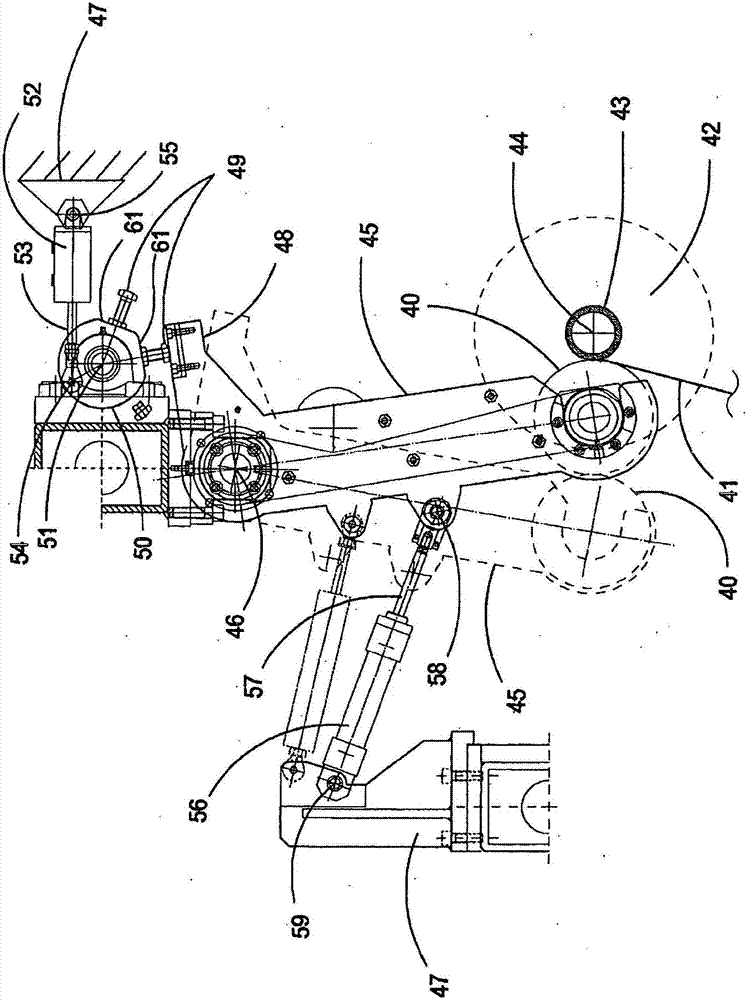

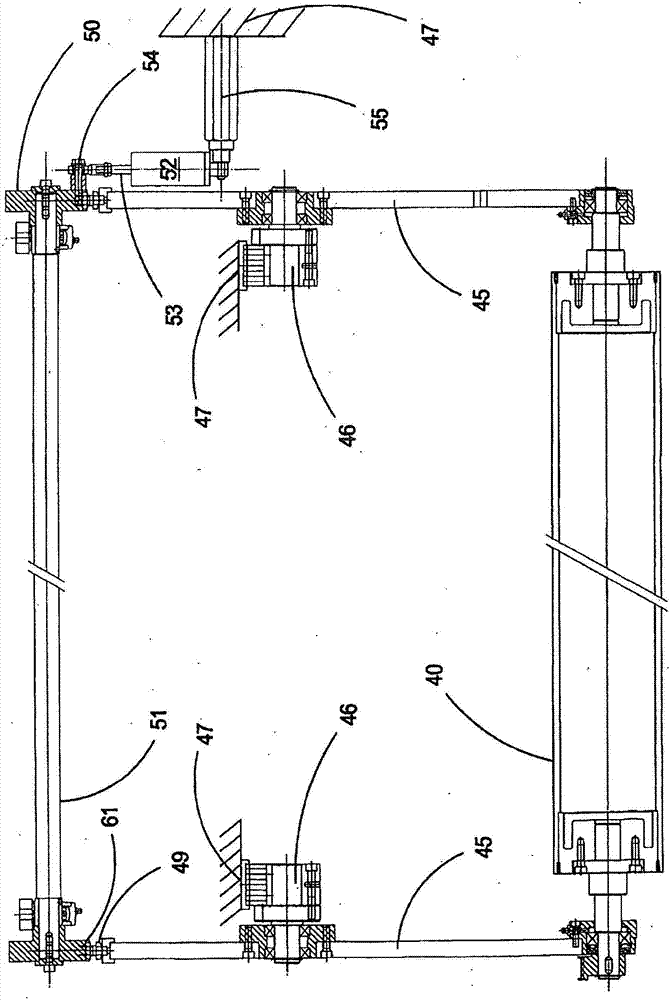

[0032] As stated, figure 1 and figure 2 A first embodiment of an automatic positioning group produced according to the invention in a machine for winding plastic film onto rolls is shown, wherein said machine is only partially shown.

[0033] In particular, the first automatic positioning group is adapted to determine the correct position of the contact roller 40 on the film 41 wound onto the roll 42 produced on the core 43 positioned on the main shaft 44 .

[0034] Thus, the automatic positioning group according to the invention automatically positions the oscillating operating element relative to the core 43 or the membrane 41 , wherein the size of the diameter of the core or the final roll on which the membrane is wound varies.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com