Silver ornament alloy taking silver as main component

A silver jewelry and alloy technology, which is applied in the field of silver jewelry silver alloy and silver jewelry alloy, can solve problems such as utensils and jewelry are easy to be scratched, damaged, jewelry is not durable, and the surface is easy to oxidize and change color, so as to improve the service life and appearance quality , Improving the effect of health care and improving the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1 A silver jewelry alloy with silver as the main component in this example is prepared from the following components in parts by weight: 93 parts of silver; 4 parts of copper; 2 parts of titanium; and 1 part of chromium.

[0009] After weighing the components with a purity of 99.9% according to the above weight ratio, put them in a vacuum furnace in turn, with a vacuum degree of 1-5Pa, raise the temperature to 1860°C-1890°C, stir evenly after constant temperature for 1 hour, and pour into the mold In the middle, the rectangular silver alloy is made after cooling at a speed of 30 minutes.

Embodiment 2

[0010] Example 2 In this example, a silver jewelry alloy with silver as the main component is prepared from the following components in parts by weight: 93 parts of silver; 3 parts of copper; 3 parts of titanium; and 1 part of chromium.

[0011] After weighing the components with a purity of 99.96% according to the above weight ratio, put them in a vacuum furnace in sequence, with a vacuum degree of 1-5Pa, raise the temperature to 1860°C-1890°C, stir evenly after constant temperature for 1 hour, and pour into the mold In the middle, the rectangular silver alloy is made after cooling at a speed of 30 minutes.

Embodiment 3

[0012] Example 3 A silver jewelry alloy mainly composed of silver in this example is prepared from the following components in parts by weight: 93 parts of silver; 3 parts of copper; 2 parts of titanium; and 2 parts of chromium.

[0013] After weighing the components with a purity of 99.9% according to the above weight ratio, put them in a vacuum furnace in turn, with a vacuum degree of 1-5Pa, raise the temperature to 1860°C-1890°C, stir evenly after constant temperature for 1 hour, and pour into the mold In the middle, the rectangular silver alloy is made after cooling at a speed of 30 minutes.

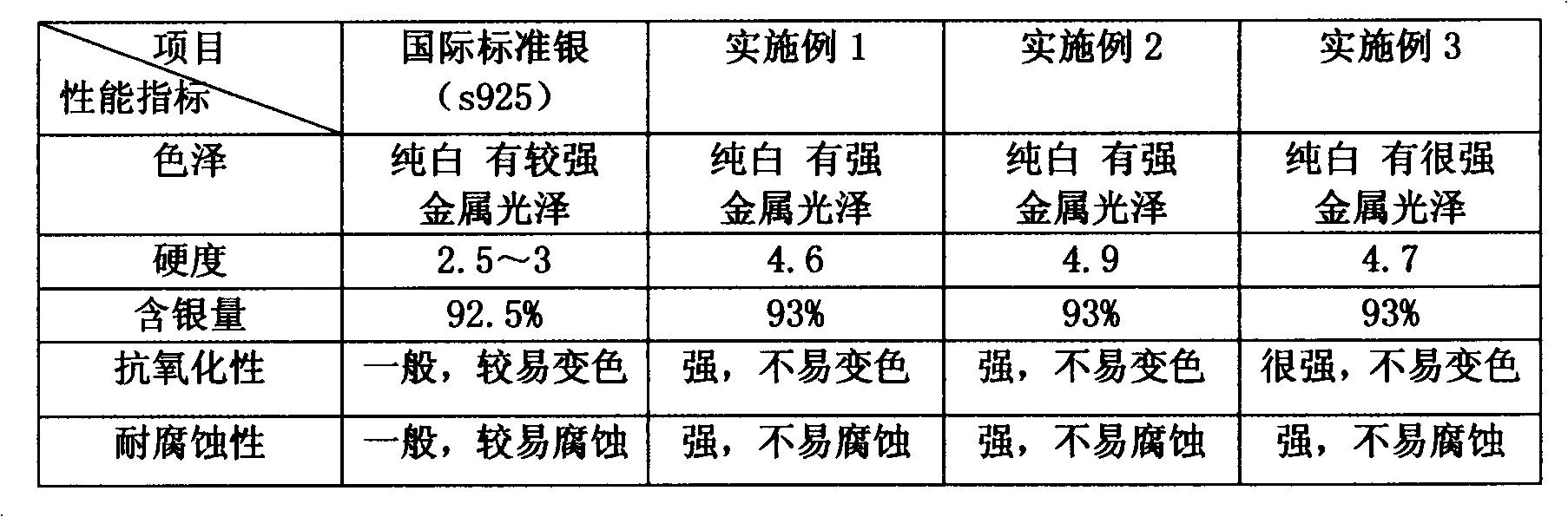

[0014] The silver jewelry alloy with silver as the main component of the present invention is tested, and compared with the s925 international standard pure silver, the silver jewelry alloy of the present invention has a brighter (whiter) color, has the characteristics of oxidation resistance and corrosion resistance, and is harder. The hardness can reach 4.5-5.2, which is more durab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com