Silver alloy and manufacturing technology and application thereof

A manufacturing process and silver alloy technology, applied in silver alloy and its manufacturing process and application fields, can solve the problems of toughness and stable surface properties at the same time, and achieve good anti-tarnish performance, stable surface properties, and good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

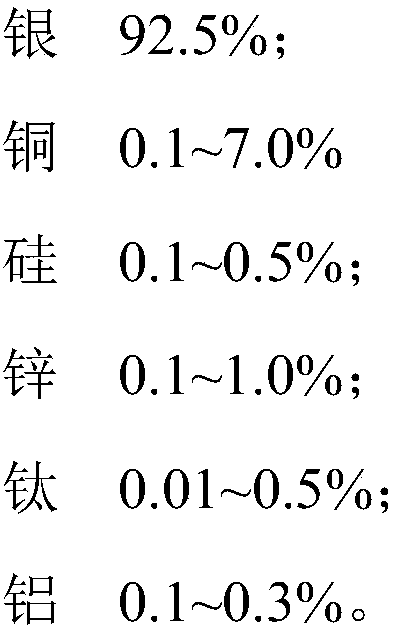

[0059] A silver alloy, according to 100% by weight, said silver alloy contains the following components:

[0060] Silver 92.5%;

[0061] Copper 6.15%

[0062] Silicon 0.1%;

[0063] Zinc 0.5%;

[0064] Titanium 0.2%;

[0065] Aluminum 0.1%;

[0066] Tin 0.05%;

[0067] Indium 0.2%;

[0068] Yttrium 0.2%.

[0069] The manufacturing process of described silver alloy comprises the steps:

[0070] 1) each metal element of the silver alloy component provided by embodiment 1 is mixed until uniform;

[0071] 2) At a vacuum of 10 -1 High-frequency vacuum melting is carried out in a Pa vacuum induction melting furnace with a melting temperature of 900°C. After all the components are melted, high-purity argon is introduced into it as a protective atmosphere and cast into silver alloy strips;

[0072] 3) placing the silver alloy strip in an environment of 760° C. for homogenization heat treatment for 9 hours, and then cold pressing at room temperature to form a silver alloy bil...

Embodiment 2

[0077] A silver alloy, according to 100% by weight, said silver alloy contains the following components:

[0078] Silver 92.5%;

[0079] Copper 6.9%

[0080] Silicon 0.1%;

[0081] Zinc 0.1%;

[0082] Titanium 0.02%;

[0083] Aluminum 0.1%;

[0084] Tin 0.05%;

[0085] Germanium 0.2%;

[0086] Yttrium 0.03%.

[0087] The manufacturing process of described silver alloy comprises the steps:

[0088] 1) each metal element of the silver alloy component that embodiment 2 provides is mixed to uniform;

[0089] 2) At a vacuum of 10 -1 High-frequency vacuum melting is carried out in a vacuum induction melting furnace in Pa, the melting temperature is 1050°C, after all the components are melted, high-purity argon is introduced into it as a protective atmosphere, and cast into silver alloy strips;

[0090] 3) placing the silver alloy strip in an environment of 630° C. for homogenization heat treatment for 7 hours, and then cold pressing at room temperature to form a silver all...

Embodiment 3

[0095] A silver alloy, according to 100% by weight, said silver alloy contains the following components:

[0096] Silver 92.5%;

[0097] Copper 5.0%

[0098] Silicon 0.5%;

[0099] Zinc 0.5%;

[0100] Titanium 0.2%;

[0101] Aluminum 0.1%;

[0102] Tin 0.05%;

[0103] Indium 0.65%;

[0104] Niobium 0.5%.

[0105] The manufacturing process of described silver alloy comprises the steps:

[0106] 1) each metal element of the silver alloy component provided by embodiment 3 is mixed until uniform;

[0107] 2) At a vacuum of 10 -1 High-frequency vacuum melting is carried out in a Pa vacuum induction melting furnace with a melting temperature of 1000°C. After all the components are melted, high-purity argon is introduced into it as a protective atmosphere, and cast into silver alloy strips;

[0108] 3) placing the silver alloy strip in an environment of 800°C for homogenization heat treatment for 5 hours, and then cold pressing at room temperature to form a silver alloy bil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com