Light transmitting cement layer, photovoltaic building material and preparation method thereof

A technology for cement layer and building materials, applied in construction, manufacturing tools, building structure, etc., can solve problems such as low photon transmittance and reduced efficiency of photovoltaic modules, and achieve high light transmittance, broaden applications, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

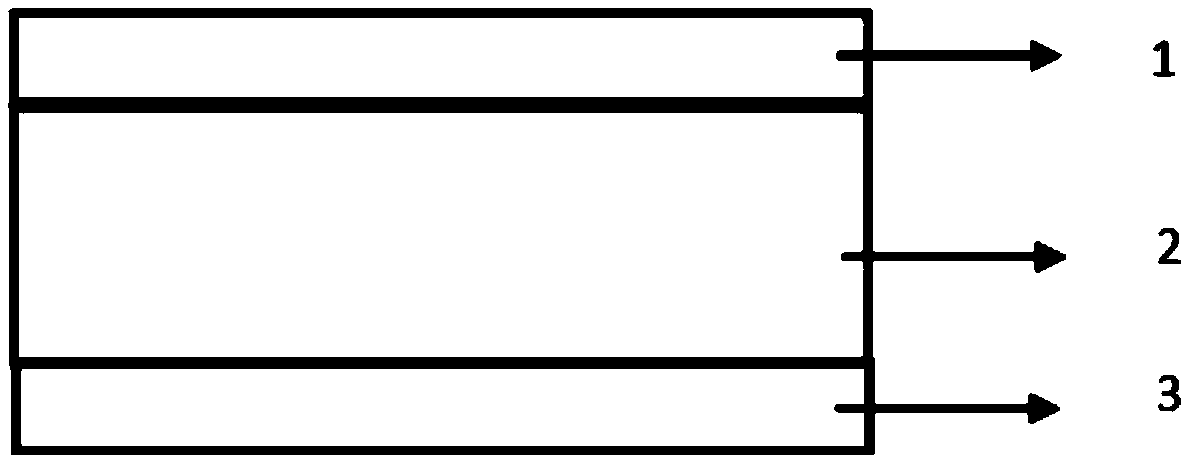

[0039] Prepare a light-transmitting cement layer on the surface of the solar cell obtained, comprising the following steps:

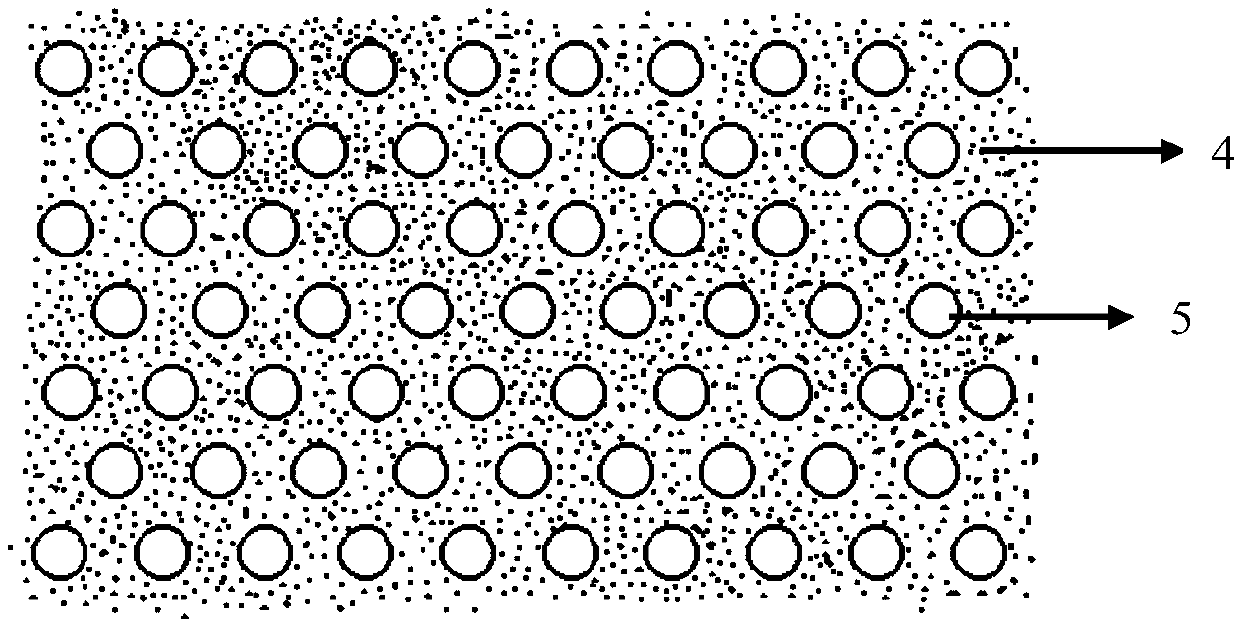

[0040] A light-transmitting cement layer is prepared on the prepared solar cell layer, and on the surface of the light-transmitting cement layer, the surface area of the light-transmitting resin accounts for 10% of the surface area of the light-transmitting cement layer.

[0041] Specific steps are as follows:

[0042] 1) Place the mold of the prefabricated light-transmitting resin unit on the surface of the solar cell layer, stir the light-transmitting resin, pour it into the mold for preparing the light-transmitting resin on the solar cell layer, remove the mold after hardening, and obtain the prefabricated transparent resin unit. Photoresin unit;

[0043] 2) Pour cement mortar into the gaps of the prefabricated light-transmitting resin units obtained in step 2), and after curing, polish and polish to obtain a light-transmitting cement layer.

...

Embodiment 2

[0048] Prepare a light-transmitting cement layer on the surface of the solar cell obtained, comprising the following steps:

[0049] A light-transmitting cement layer is prepared on the prepared solar cell layer, and on the surface of the light-transmitting cement layer, the surface area of the light-transmitting resin accounts for 50% of the surface area of the transparent cement layer.

[0050] Specific steps are as follows:

[0051] 1) Place the mold of the prefabricated light-transmitting resin unit on the surface of the solar cell layer, stir the light-transmitting resin, pour it into the mold for preparing the light-transmitting resin on the solar cell layer, remove the mold after hardening, and obtain the prefabricated transparent resin unit. Photoresin unit;

[0052] 2) Pour cement mortar into the gaps of the prefabricated light-transmitting resin units obtained in step 2), and after curing, polish and polish to obtain a light-transmitting cement layer.

[0053] ...

Embodiment 3

[0057] Prepare a light-transmitting cement layer on the surface of the solar cell obtained, comprising the following steps:

[0058] A light-transmitting cement layer is prepared on the prepared solar cell layer, and on the surface of the light-transmitting cement layer, the surface area of the light-transmitting resin accounts for 50% of the surface area of the light-transmitting cement layer.

[0059] Specific steps are as follows:

[0060] 1) Place the mold of the prefabricated light-transmitting resin unit on the surface of the solar cell layer, stir the light-transmitting resin, pour it into the mold for preparing the light-transmitting resin on the solar cell layer, remove the mold after hardening, and obtain the prefabricated transparent resin unit. Photoresin unit;

[0061] 2) Pour cement mortar into the gaps of the prefabricated light-transmitting resin units obtained in step 2), and after curing, polish and polish to obtain a light-transmitting cement layer.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com