A preparation method of composite sheathed iron-based superconducting wire

An iron-based superconducting and sheathing technology, which is applied in the usage of superconducting elements, superconducting devices, cable/conductor manufacturing, etc., can solve the problems of plugs being easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

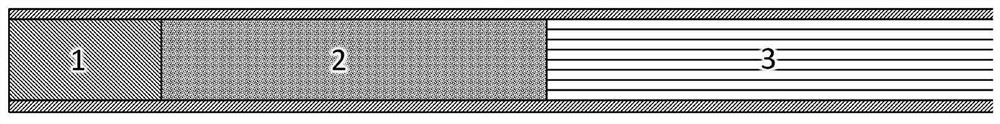

Image

Examples

Embodiment 1

[0028] (1) Take a piece with a length of 10 cm and an outer diameter of 5 mm, which is made of pure silver metal as the sheath material, and contains BaFe doped with K element 2 As 2 The wire rod of the iron-based superconducting material is packed into a pure copper metal tube with a length of 16 cm, an outer diameter of 8 mm, and a wall thickness of 1.5 mm.

[0029] (2) Use a mechanical clamping device to make the iron-based superconducting wire closely adhere to the inner wall of the pure copper metal tube at 1 cm from both ends.

[0030] (3) In an argon atmosphere inert gas glove box, use pure copper metal powder to fill both ends of the pure copper metal tube, the filling length is 2 cm, and the filled metal powder part is close to the end surface of the iron-based superconducting wire without gaps.

[0031] (4) Put two cylindrical pure tin metal plugs with an outer diameter of 5 mm and a length of 1 cm into the two ends of the pure copper metal tube, so that the inner e...

Embodiment 2

[0036] (1) 7 pieces with a length of 10 cm and an outer diameter of 2.55 mm are made of pure silver metal as the sheath material, and the composition is BaFe doped with K element 2 As 2 The wire rod of the iron-based superconducting material is packed into a copper-nickel alloy metal tube with a length of 16 cm, an outer diameter of 10 mm, and a wall thickness of 1 mm.

[0037] (2) Use a mechanical clamping device to make the iron-based superconducting wire closely adhere to the inner wall of the copper-nickel alloy metal tube at 1 cm from both ends.

[0038] (3) In an argon atmosphere inert gas glove box, use pure copper metal powder to fill both ends of the copper-nickel alloy metal tube, the filling length is 2 cm, and the filled metal powder part is tightly connected to the end surface of the iron-based superconducting wire without gaps.

[0039] (4) Put two cylindrical pure tin metal plugs with an outer diameter of 8 mm and a length of 1 cm into the two ends of the coppe...

Embodiment 3

[0044] (1) The length of 19 pieces is 16 cm, the outer diameter is 2.50 mm, and the silver-manganese alloy is used as the sheath material, and the composition is SrFe doped with Na element. 2 As 2 The wire rod of the iron-based superconducting material is packed into a pure iron metal tube with a length of 20 cm, an outer diameter of 15 mm, and a wall thickness of 1 mm.

[0045] (2) A mechanical clamping device is used to make the iron-based superconducting wire closely adhere to the inner wall of the pure iron metal tube at 1 cm from both ends.

[0046] (3) In an argon atmosphere inert gas glove box, use pure iron metal powder to fill both ends of the pure iron metal tube, the filling length is 2 cm, and the filled metal powder part is tightly connected to the end surface of the iron-based superconducting wire without gaps.

[0047] (4) Put 2 cylindrical pure lead metal plugs with an outer diameter of 13 millimeters and a length of 2 centimeters into the two ends of the pure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com