Preparation method of silver graphite electrical contact with continuous pure silver layer on side

A silver-graphite, electrical contact technology, used in circuits, electrical switches, electrical components, etc., can solve the problems of poor welding resistance, limited specifications, and difficult processing, and achieve good welding resistance and deformation. The effect of reducing and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

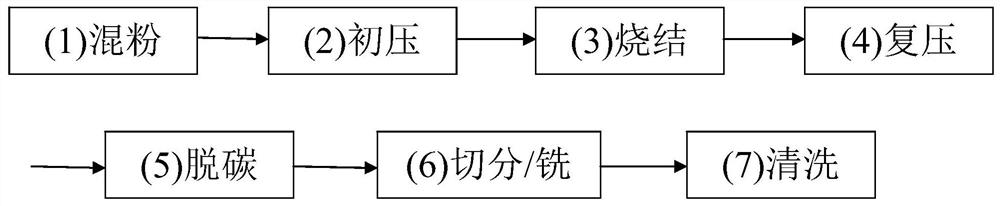

Method used

Image

Examples

Embodiment 1

[0026] 1) Mix 19kg of silver powder with 1kg of graphite powder to get AGC5 mixing powder;

[0027] 2) The AgC5 mixed powder is pressed and molded by molding method;

[0028] 3) Put the press blank in the sintering furnace and sinter it, keep warm at 940 °C for 2 hours, hydrogen protection;

[0029] 4) Press the blank with 11t / cm 2 Pressure is carried out for compound pressure;

[0030] 5) The pressing blank is placed in the decarburization furnace at 600 °C for decarburization;

[0031] 6) The product is divided into two from the middle position of the thickness to get two contacts;

[0032] 7) Grind and polish the contacts, then dry them to obtain any structure of silver graphite electric contacts with a continuous sterling silver layer on the side.

[0033] The present embodiment finally obtains an arbitrary structure having a continuous sterling silver layer on the side of the AGC5 electric contact, compared with the conventional arbitrary structure AGC5 electric contact, the ...

Embodiment 2

[0035] 1) Mix 48kg silver powder with 2kg graphite powder to obtain AGC4 mixing powder;

[0036] 2) The AgC4 mixed powder is pressed and molded by molding method;

[0037] 3) Put the pressing blank in the sintering furnace and sinter it, keep warm at 900 °C for 3 hours, hydrogen protection;

[0038] 4) Press the blank with 10t / cm 2 Pressure is carried out for compound pressure;

[0039] 5) Place the press blank in the decarburization furnace at 700 °C to decarburize;

[0040] 6) Mill off one side of the silver layer of the product with special equipment, and retain the other side of the silver layer for welding to obtain a single-piece contact;

[0041] 7) Grind and polish the contacts, then dry them to obtain any structure of silver graphite electric contacts with a continuous sterling silver layer on the side.

Embodiment 3

[0043] 1) Mix 9.7kg silver powder with 0.3kg graphite powder to obtain AgC3 mixing powder;

[0044] 2) The AgC3 mixed powder is pressed and molded by molding method;

[0045] 3) Put the press blank in the sintering furnace and sinter it, keep warm at 860 °C for 4 hours, hydrogen protection;

[0046] 4) Press the blank with 9t / cm 2 Pressure is carried out for compound pressure;

[0047] 5) Place the press blank in the decarburization furnace at 800 °C to decarburize;

[0048] 6) The product is divided into two from the middle position of the thickness to get two contacts;

[0049] 7) Grind and polish the contacts, then dry them to obtain any structure of silver graphite electric contacts with a continuous sterling silver layer on the side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com