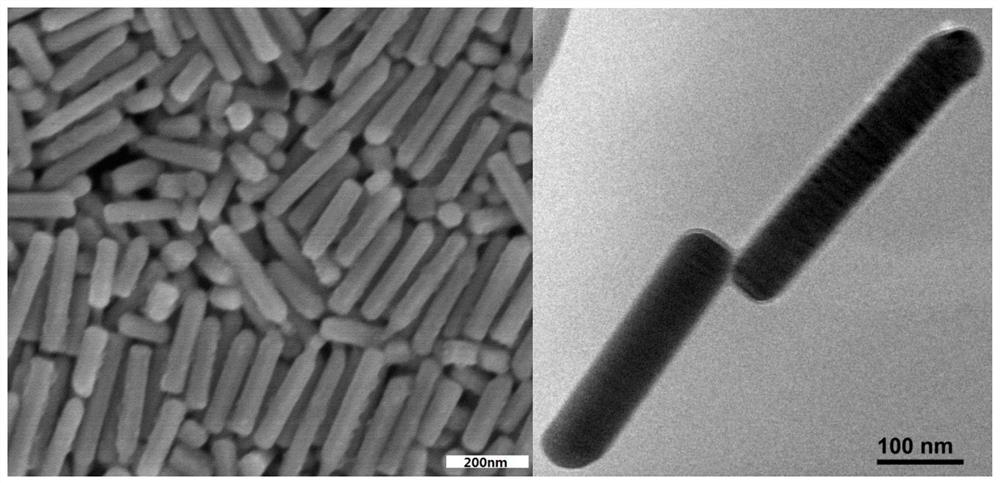

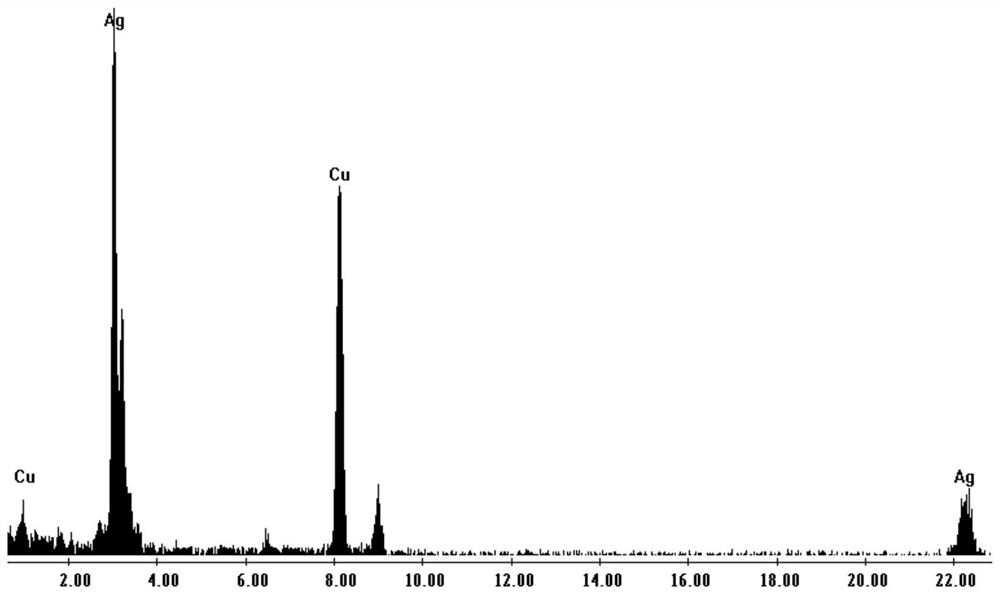

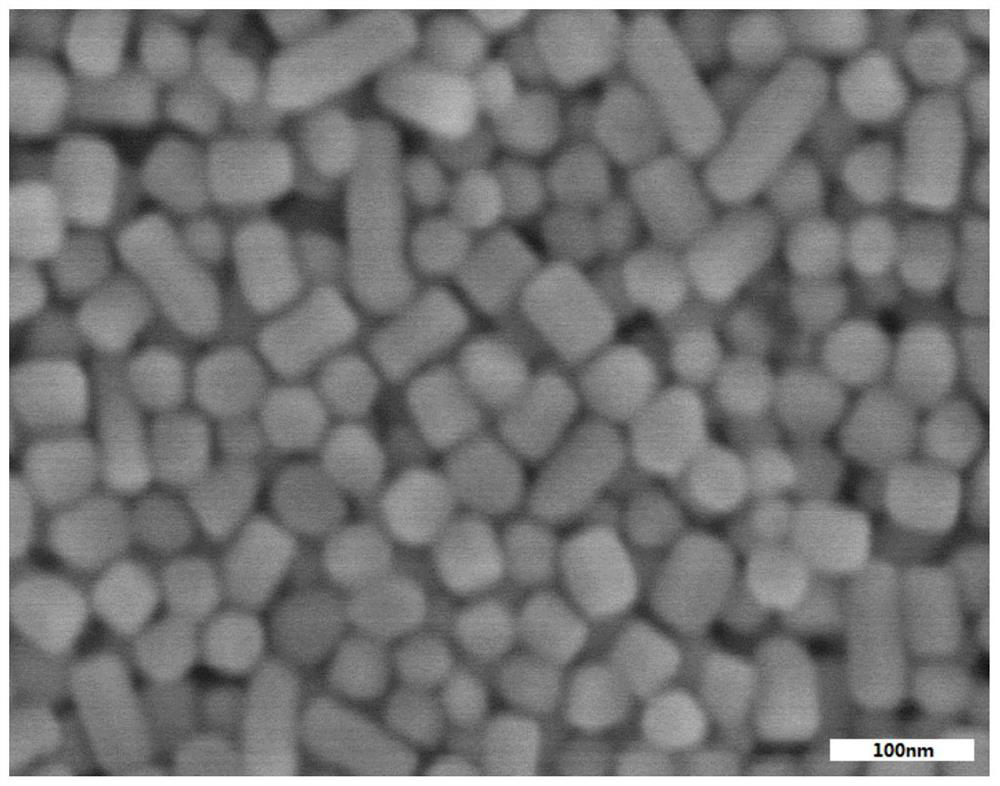

A kind of pure silver nanorod with hexagonal cross section and preparation method thereof

A technology of hexagonal and nanorods, which is applied in the field of pure silver nanorods with hexagonal cross-sections and its preparation, can solve the problem of poor anisotropic differentiation of silver nanoparticles, instability of silver nanoparticles, and poor size controllability and other problems, to achieve the effect of uniform size, mild growth environment, stable and uniform output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of pure silver nanorods with hexagonal cross-section:

[0026] 1. First prepare silver nanoparticles with sodium alginate as carrier:

[0027] At room temperature, 50ml of silver nitrate aqueous solution with a concentration of 0.01mol / L was added to 500g of sodium alginate aqueous solution with a mass fraction of 0.01%, and after stirring for 30 minutes in the dark, 25ml of sodium borohydride with a concentration of 0.1mol / L was injected. The aqueous solution, reacted for one hour, was naturally dialyzed in deionized water for 3 to 5 days using a dialysis bag to obtain silver nanoparticles with sodium alginate as a carrier. The concentration of the silver nanoparticle dispersion solution was 8.696×10 -4 mol / L.

[0028] 2. Preparation of pure silver nanorods:

[0029] Under the condition of 26 ℃ ~ 27 ℃, 15 ml of sodium dodecyl sulfate aqueous solution with a concentration of 0.005 mol / L was stirred for 30 minutes, and then 0.4 ml of silver nitrate...

Embodiment 2

[0032] 1. First prepare silver nanoparticles with sodium alginate as carrier:

[0033] The same method steps as in Example 1 were used to prepare silver nanoparticles with sodium alginate as a carrier.

[0034] 2. Preparation of pure silver nanorods:

[0035] Under the condition of 26 ℃ ~ 27 ℃, 20 ml of sodium dodecyl sulfate aqueous solution with a concentration of 0.005 mol / L was stirred for 30 minutes, and then 0.5 ml of silver nitrate aqueous solution with a concentration of 0.01 mol / L was rapidly added in sequence, and 0.07 ml of a concentration of 0.1mol / L of ascorbic acid aqueous solution and 0.04ml of silver nanoparticle dispersed aqueous solution with a concentration of 8.696×10-4mol / L were maintained in a stirring state for 3h, then centrifuged at 5500 rpm for 15~20min, and the supernatant was removed. Add an equal volume of aqueous solution to maintain the same rotation speed and time for the second centrifugation, remove the supernatant again, and the lower layer ...

Embodiment 3

[0038] 1. First prepare silver nanoparticles with sodium alginate as carrier:

[0039] The same method steps as in Example 1 were used to prepare silver nanoparticles with sodium alginate as a carrier.

[0040] 2. Preparation of pure silver nanorods:

[0041] Under the condition of 26 ℃ ~ 27 ℃, 30 ml of sodium dodecyl sulfate aqueous solution with a concentration of 0.005 mol / L was stirred for 30 minutes, and then 0.8 ml of silver nitrate aqueous solution with a concentration of 0.01 mol / L was rapidly added in sequence, and 0.1 ml of a concentration of After 0.1 mol / L of ascorbic acid aqueous solution was reacted for 3 to 5 minutes, 0.04 ml of silver nanoparticle dispersion aqueous solution with a concentration of 8.696×10-4 mol / L was added, and after the reaction was maintained for 3 hours, the solution was centrifuged at 5500 rpm for 15 minutes. ~20min, remove the supernatant liquid, add an equal volume of aqueous solution to maintain the same rotation speed and time for a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com