Tarnish-resistant sterling silver alloys

a silver alloy and alloy technology, applied in the field of tarnish-resistant sterling silver alloys, can solve the problems of affecting the production of large-scale silver products, the tarnish resistance of silver alloys is increased, and the fine silver is generally too soft for large-scale silver production, so as to achieve a remarkable combination of hardness and tarnish resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

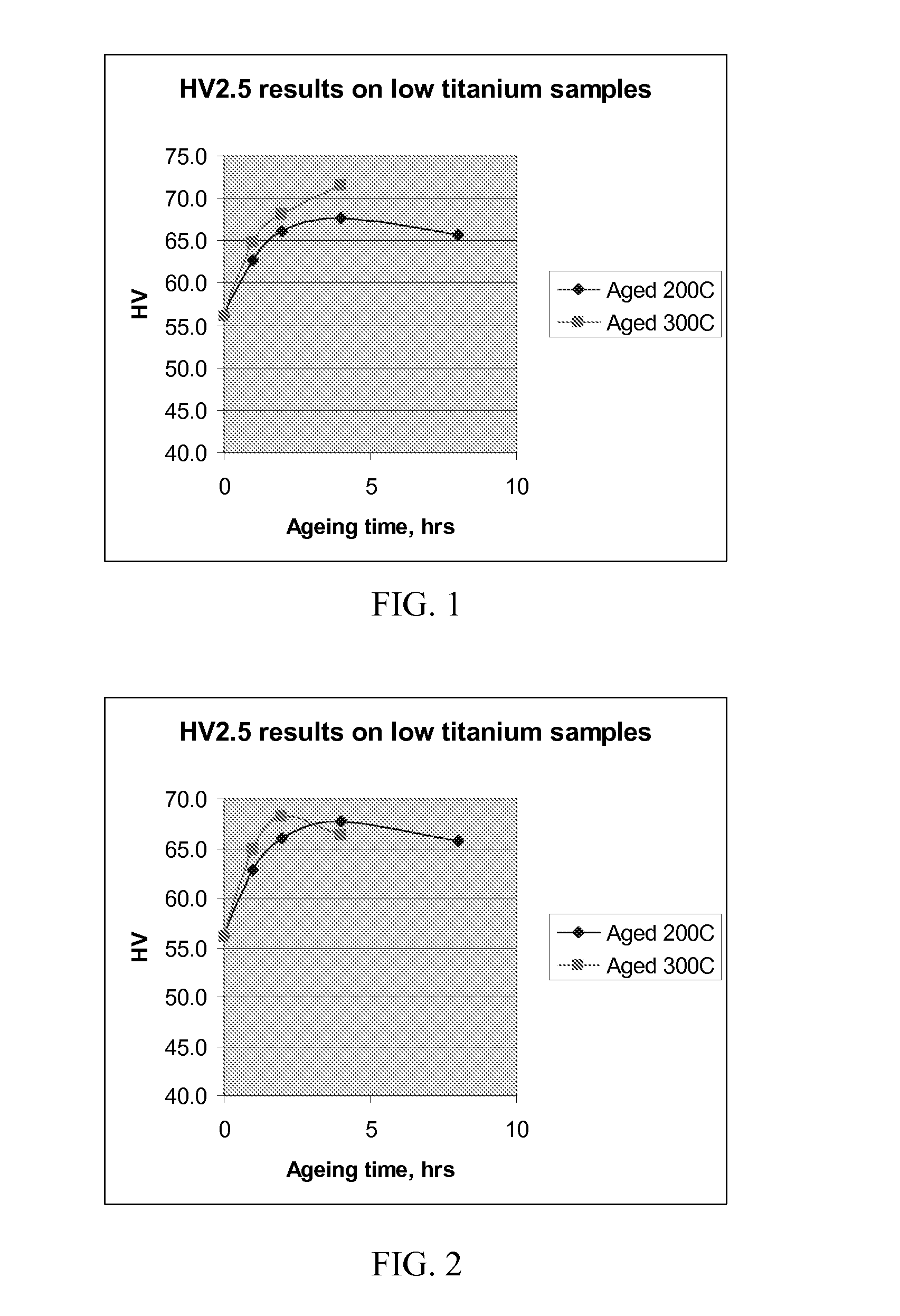

Image

Examples

example 1

Test of Furnace Procedures

[0103]A test melt is conducted using fine silver in a zirconia crucible to test the furnace procedures. The chamber was charged, the doors sealed, pumped down, purged with dry nitrogen, pumped down again and the backfilled with Argon to 730 tor. Temperatures were monitored optically. Everything went well on the first melt until the superheat reached a point where there substantial silver volatilization began. It reached the point where the optical pyrometer was obscured and stopped working. The melt was allowed to cool and poured the ingot. Upon opening the chamber, there was very noticeable coating of silver dust on most of the chamber interior and furnace parts. However, the fine dust wiped off easily with a cloth. The zirconia crucible was clean, with no evidence of deterioration.

[0104]When 7% Ti material was used, which required a higher temperature to melt and was more difficult to reach, a similar volatilization occurred, perhaps even slight worse, bu...

example 2

Melting and Casting of Ti—Ag Alloys

[0113]Melting / casting of AgTi was also conducted with two 100 g melts of mixed process scrap AgTi to make coupons for workability and other tests and ring castings. A graphite crucible was used. Coupling with the crucible was good, but the heating of the charge was mainly by conduction and radiation from the crucible rather than direct induction. Everything was clear but relatively slow. A clear melt was obtained with very little stirring. The melt was poured as though it were fine silver. The pyro-meter said 1100° C. when the cast button was pressed. The investment mould had been placed in the furnace at 1000° C. at the outset. It was not certain what the temperature of the mould was by the time the melt hit it, but the visible surface was below red heat. Generally, the cast surfaces were good, and there were no obvious shrinkage problems and, surprisingly, no Ti—C reaction. There was a residual shell in the crucible which was higher in titanium t...

example 3

Making of Ti—Ag Alloy Tube

[0114]An alloy tube is made by extrusion, which is used to make flat wedding bands by cold drawing and machining. For example, they can be plain flat bands, approximately 6 mm wide by 2 mm high in US Finger Size 10 (British T+−U). The XRF tests show Ti concentration between 2.5% and 3.5%. This is lower than the 7% target, because a part of Ti was not completely dissolved in the melt.

[0115]When a zirconia crucible is used, it was observed that titanium probably reacted with certain materials in the crucible; therefore, in the present invention a durable refractory container for melting needs to be selected. As known in the art, although it is possible to calculate the energies of formation of several “perfect ratio” titanium oxides, when titanium competes with another oxide for oxygen it is highly unlikely to do so under perfect ratio conditions. Although oxide on solid titanium can be self-protective, whether that applies to a liquid titanium or silver inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| casting temperatures | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com