Treatment method for surface discoloration of sterling silver products

A technology of surface discoloration and treatment method, which is applied in the field of surface discoloration treatment of pure silver products, can solve the problems of complex types of agents and high cost, and achieve the effects of high cost performance, low cost and reduced silver loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

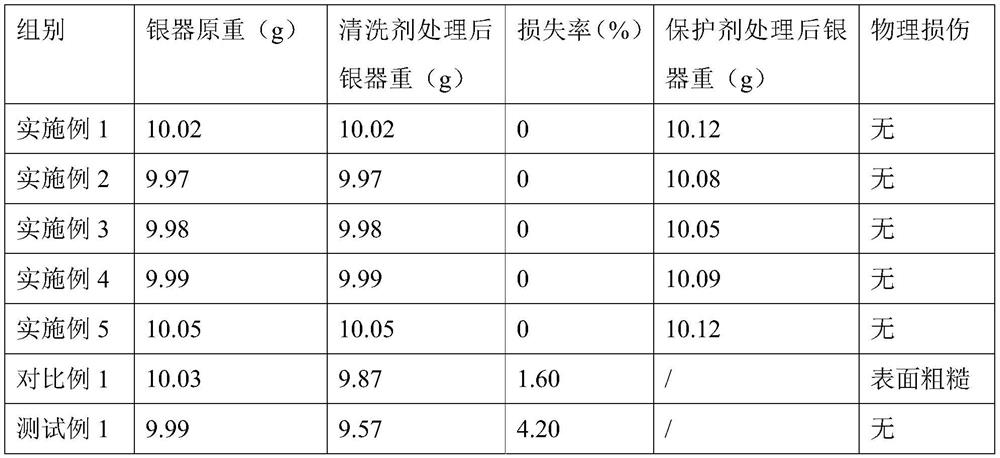

Examples

Embodiment 1

[0031] Raw material composition:

[0032] Cleaning agent (parts by weight): 10 parts of concentrated ammonia water, 3 parts of sodium cyanide, 20 parts of glucose, 12 parts of inorganic alkali and 20 parts of polyol.

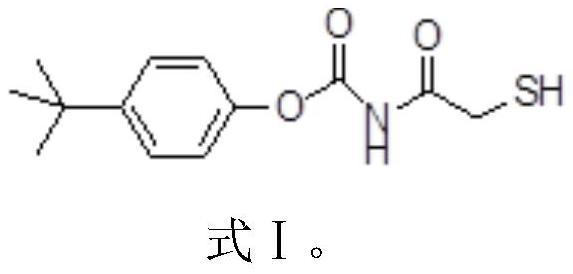

[0033] Protective agent:

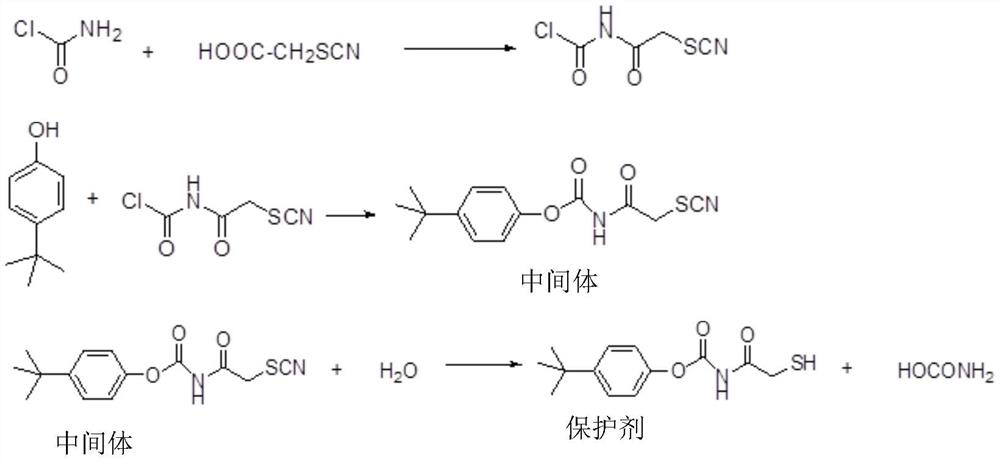

[0034] The protective agent is prepared by the following method:

[0035] S1. Preparation of intermediates: Weigh 1.1 mol p-tert-butylphenol, 1.2 mol α-bromoacetic acid, 1 mol ammonium thiocyanate, and 1.5 mol aminoacyl chloride in a certain proportion and add them to a three-necked bottle filled with 200 mL 95% ethanol , and then add 5mL acetic acid; when heating, when a brown precipitate appears, the solution turns red, and the solvent is refluxed for 20min, and the mixture is poured into a beaker placed in an ice bath, at this time, a yellow-brown solid is precipitated, and filtered under reduced pressure to obtain as an intermediate;

[0036] S2. Preparation of protective agent: Dissolve 1 mol of the intermediate in absolute e...

Embodiment 2

[0049] Raw material composition:

[0050] Cleaning agent (parts by weight): 20 parts of concentrated ammonia water, 5 parts of sodium cyanide, 30 parts of glucose, 17 parts of inorganic alkali and 50 parts of polyol.

[0051] Protective agent:

[0052] The protective agent is prepared by the following method:

[0053] S1. Preparation of intermediates: Weigh 1.1 mol p-tert-butylphenol, 1.2 mol α-bromoacetic acid, 1 mol ammonium thiocyanate, and 1.5 mol aminoacyl chloride in a certain proportion and add them to a three-necked bottle filled with 200 mL 95% ethanol , and then add 5mL acetic acid; when heating, when a brown precipitate appears, the solution turns red, add solvent and reflux for 20-50min, pour the mixture into a beaker placed in an ice bath, at this time, a yellow-brown solid precipitates, filter under reduced pressure , obtained as an intermediate;

[0054] S2. Preparation of protective agent: Dissolve 1 mol of the intermediate in absolute ethanol, then add 10...

Embodiment 3

[0060] Raw material composition:

[0061] Cleaning agent (parts by weight): 12 parts of concentrated ammonia water, 4 parts of sodium cyanide, 22 parts of glucose, 14 parts of inorganic alkali and 25 parts of polyhydric alcohol.

[0062] Protective agent:

[0063] The protective agent is prepared by the following method:

[0064] S1. Preparation of intermediates: Weigh 1.1 mol p-tert-butylphenol, 1.2 mol α-bromoacetic acid, 1 mol ammonium thiocyanate, and 1.5 mol aminoacyl chloride in a certain proportion and add them to a three-necked bottle filled with 200 mL 95% ethanol , and then add 5mL acetic acid; when heating, when a brown precipitate appears, the solution turns red, add solvent and reflux for 20-50min, pour the mixture into a beaker placed in an ice bath, at this time, a yellow-brown solid precipitates, filter under reduced pressure , obtained as an intermediate;

[0065] S2. Preparation of protective agent: Dissolve 1 mol of the intermediate in absolute ethanol,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com