Dynamic heat flow sensor integrating thermoelectric potential effect

A dynamic heat flow and sensor technology, which is applied to calorimeters, thermometers and instruments using electrical/magnetic components directly sensitive to heat, etc., can solve the problems of high processing cost, wide application, complex structure of dynamic heat flow sensors, etc. Achieve the effect of low cost, easy quality control, and improved thermal response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0028] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

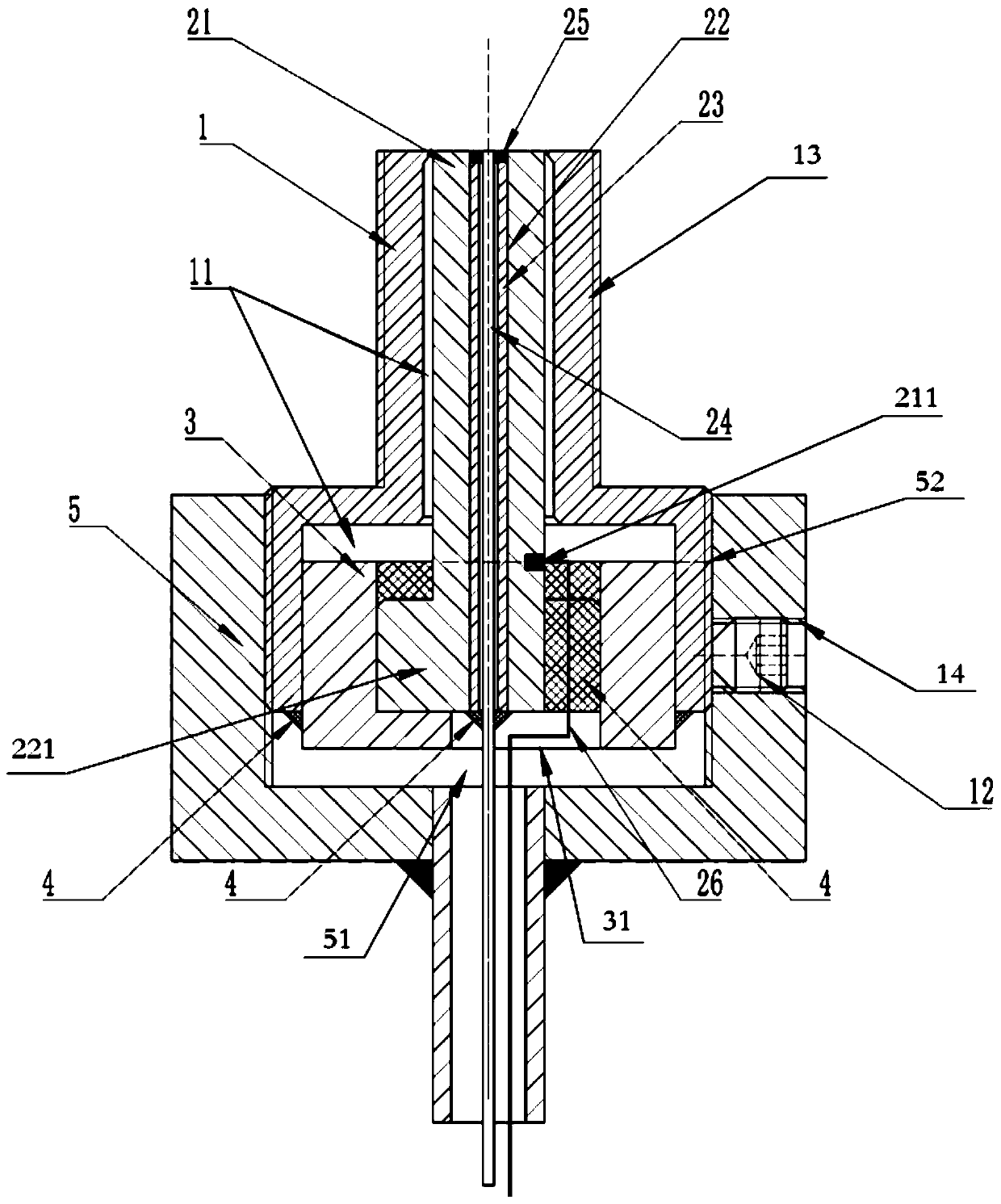

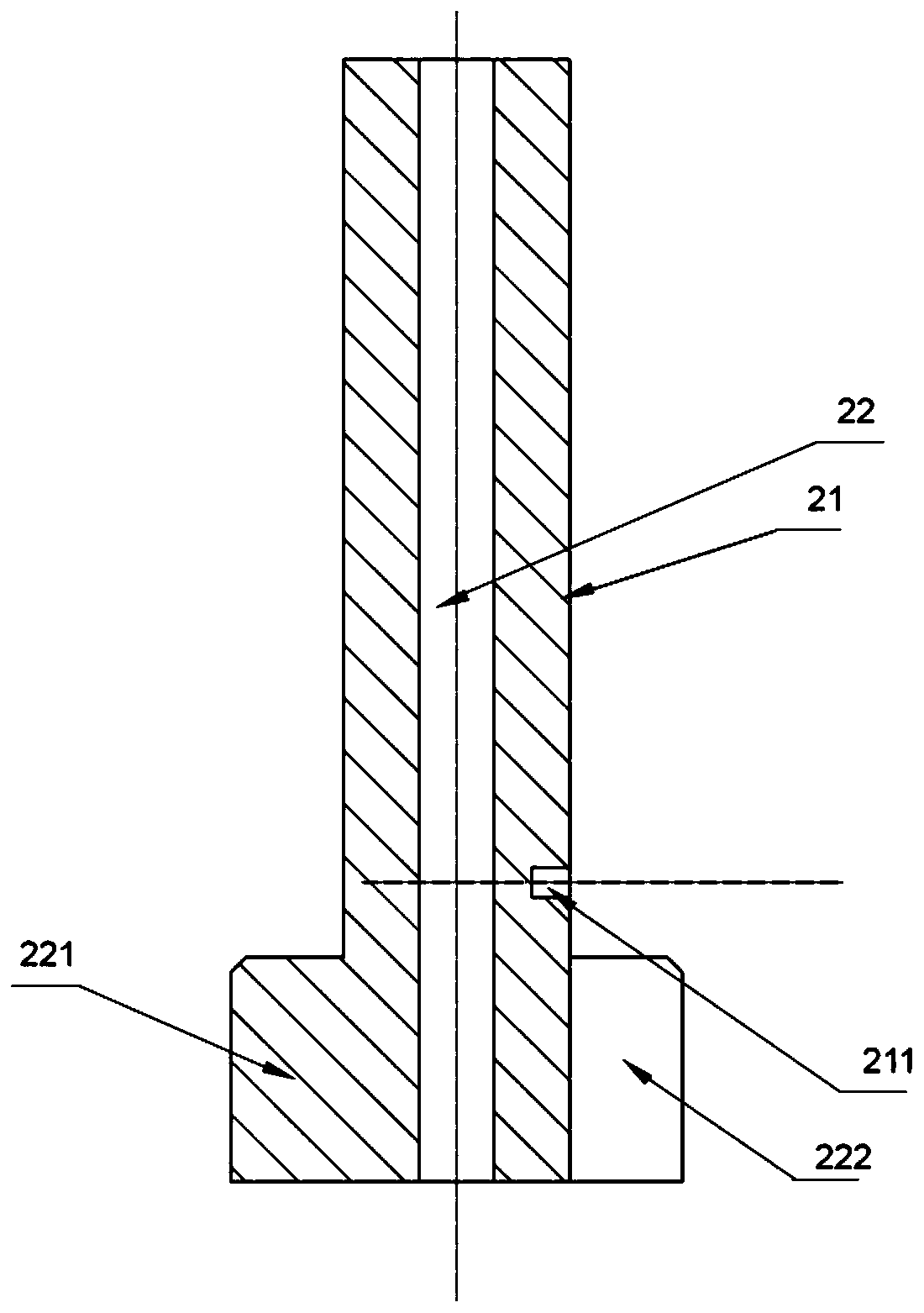

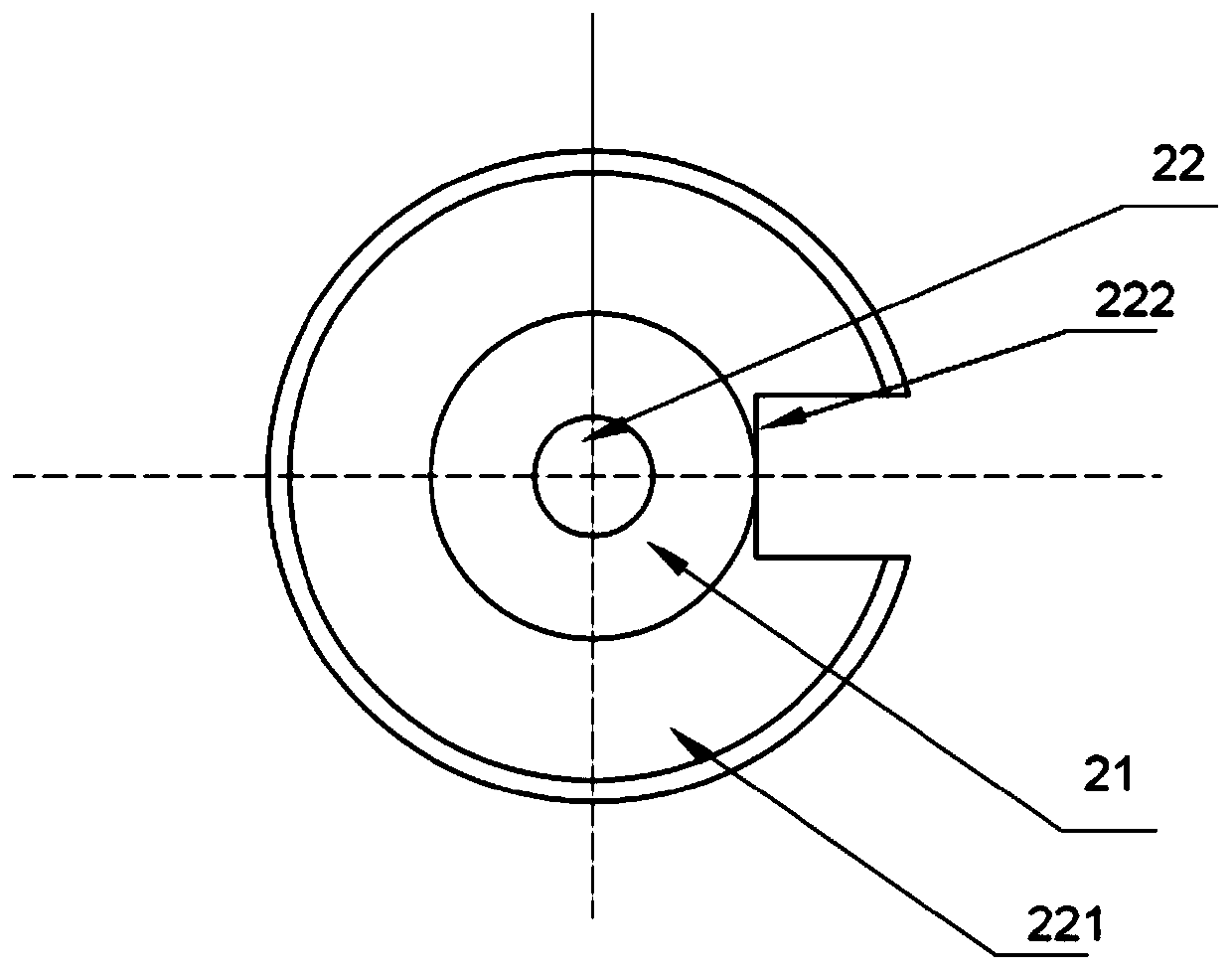

[0029] Such as Figure 1-4 A dynamic heat flow sensor with heat collection potential effect is shown, including:

[0030] The T-shaped packaging shell 1 is provided with a cavity I11 inside, and the outer wall of the smaller end of the T-shaped packaging shell 1 is provided with a thread I13;

[0031] The phlogopite heat insulation ring 3 is fixedly connected to the receiving cavity I11 at the larger end of the T-shaped package shell through a high-temperature epoxy resin adhesive 4, and the phlogopite heat insulation ring 3 is a hollow circular phlogopite heat insulation ring. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com