Device and method for detecting neglected loading of magnet buckle of food packaging box

A food packaging box and detection device technology, applied in the printing field, can solve problems such as shedding, manpower and material resources, waste of raw materials, and impact on delivery time, and achieve the effect of reducing waste products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention will be further described,

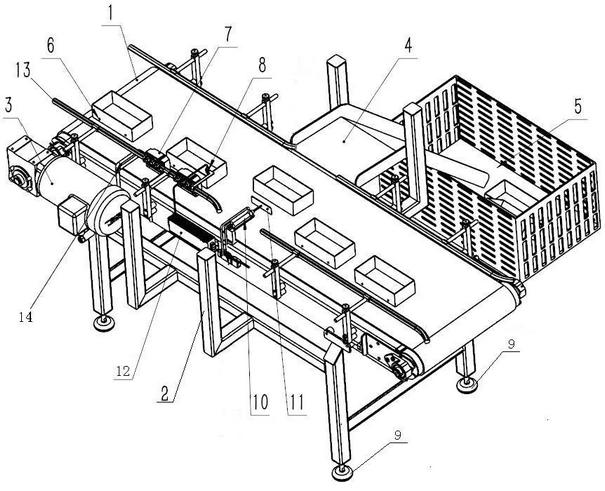

[0019] refer to figure 1 , a magnetic buckle missing detection device for food packaging boxes, including a belt bracket 2 and a conveyor belt installed on the belt bracket, the conveyor belt is used for the packaging of the conveyor box, of course, the front end of the belt bracket 2 is also installed to drive the conveyor belt to work The servo transmission motor 1;

[0020] A motor controller 3 is provided adjacent to the servo transmission motor, and the motor controller 3 is a combined switch for controlling the operation or stop of the servo transmission motor.

[0021] On one side of the belt bracket, a magnet detection sensor 7, a box packaging positioning detection sensor 8 and a cylinder telescopic arm 10 are sequentially arranged longitudinally;

[0022] A control module is installed on the belt bracket, and the control module sends a work or stop command to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com