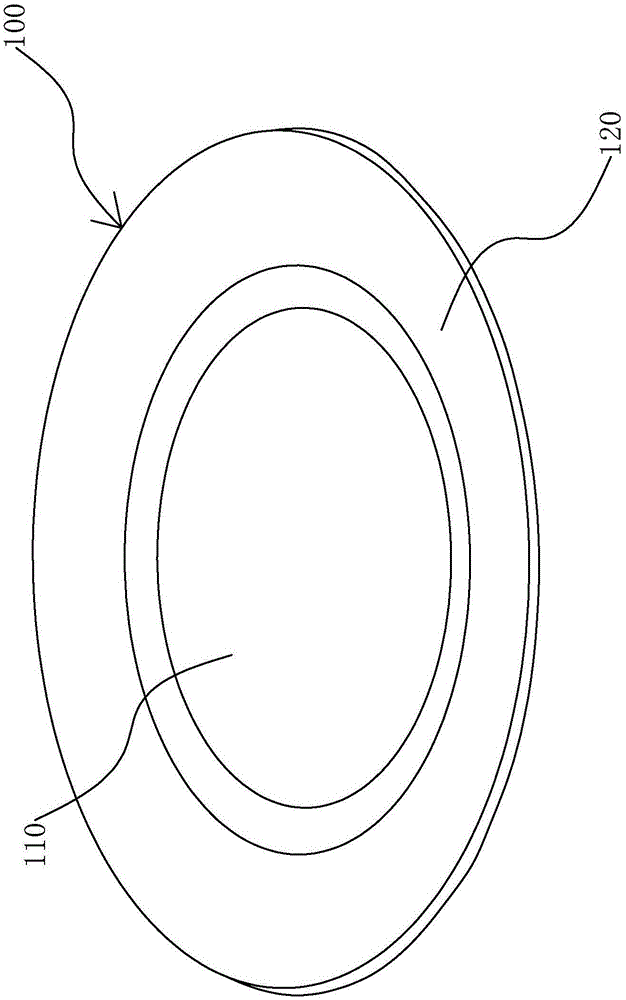

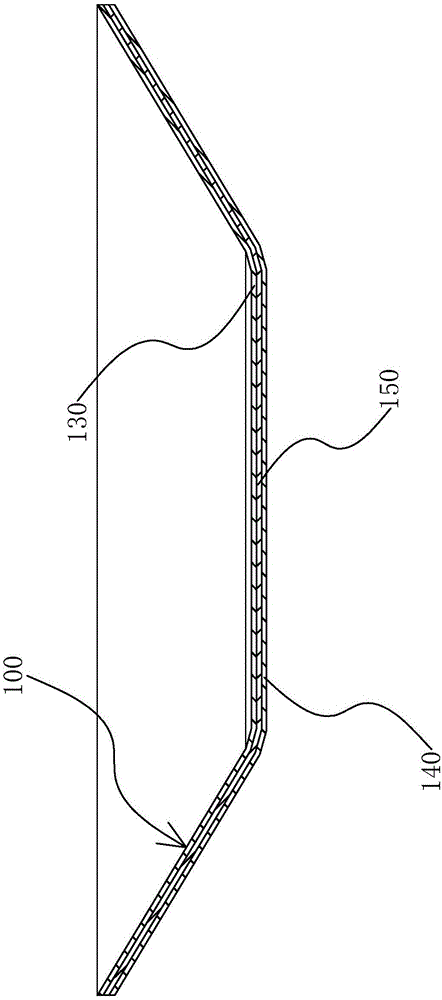

Double-color thin-wall plastic tableware and processing method thereof

A plastic tableware and processing method technology, applied in the field of tableware, can solve the problems of simple and rough materials and processing methods of disposable tableware, the quality and sanitation of tableware cannot be guaranteed, and the use is prone to dents, etc., so as to prevent scald accidents and reduce production costs. Low, not easy to spill effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

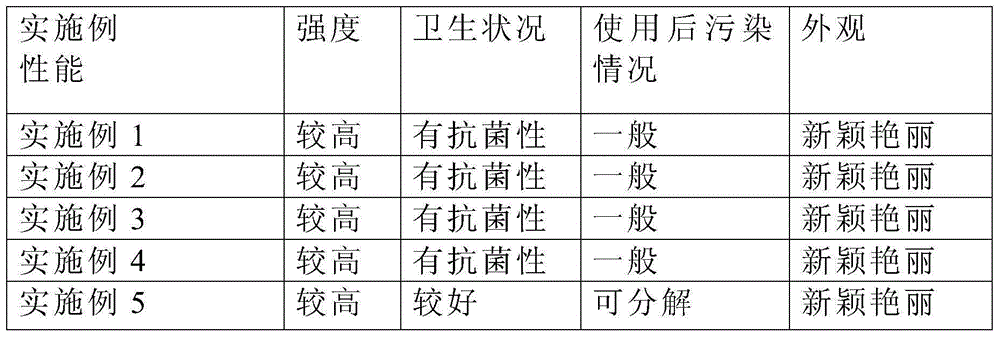

Embodiment 1

[0041] Weigh the following plastic raw materials: PP resin: 60 parts, nano-SiO 2 : 5 parts, Nano CaCO 3 : 4 parts, compound antibacterial and anti-mildew auxiliary agent: 1 part, processing aid: 5 parts, antioxidant: 0.8 parts, wherein, the composite anti-bacterial and anti-mildew auxiliary agent is nano-silver ion antibacterial agent, and the processing aid is 1 part of paraffin wax , 1 part of stearic acid, 1 part of fatty acid and its esters, 2 parts of PP-g-ST; the antioxidant is 2,6-di-tert-butylphenol.

[0042] Mix the above plastic raw materials evenly and add 1 part of toner, dry for 3 hours under the conditions of temperature at 105°C, air volume at 1750 cubic meters per hour, and wind pressure at 1250Pa, and then masticated and extruded at 160°C. Sheets of various colors.

[0043] The multi-layer sheets are stacked together for blister molding, and the colors of the sheets constituting the upper surface layer and the lower surface layer are different. Finally, afte...

Embodiment 2

[0045] Weigh the following plastic raw materials: PP resin: 70 parts, nano-SiO 2 : 6 parts, Nano CaCO 3 : 3 parts, composite antibacterial and anti-mildew auxiliary agent: 1.2 parts, processing aid: 4 parts, antioxidant: 0.6 part, wherein, described composite anti-bacterial and anti-mold auxiliary agent is vanillin compound, and processing aid is 2 parts 1 part of talcum powder, 1 part of fatty acid and its esters, 1 part of PP-g-MAH; the antioxidant is one or more phenolic antioxidants.

[0046] Mix the above plastic raw materials evenly and add 1 part of toner, dry for 4 hours under the conditions of temperature at 102°C, air volume at 1780 cubic meters per hour, and wind pressure at 1220Pa, then masticate and extrude at 170°C. Sheets of various colors.

[0047] The multi-layer sheets are stacked together for blister molding, and the colors of the sheets constituting the upper surface layer and the lower surface layer are different. Finally, after cooling, demoulding, shea...

Embodiment 3

[0049] Weigh the following plastic raw materials: PP resin: 50 parts, nano-SiO 2 : 8 parts, Nano CaCO 3 : 5 parts, composite antibacterial and mildew-proof auxiliary agent: 2 parts, processing aid: 3 parts, antioxidant: 1 part, wherein, described composite antibacterial and anti-mildew auxiliary agent is 1 part of nano-silver ion antibacterial agent, 1 part Ethyl vanillin compounds, processing aids are 1 part of silane coupling agent, 1 part of organosilicon compound, 1 part of PP-g-ST; antioxidants are 0.5 part of antioxidant 1010, 0.5 part of antioxidant 1076.

[0050] Mix the above plastic raw materials evenly and add 0.5 parts of toner, dry for 5 hours under the conditions of temperature 100°C, air volume 1800 cubic meters per hour, and wind pressure 1200Pa, and then plasticize and extrude at 150°C. Sheets of various colors.

[0051] The multi-layer sheets are stacked together for blister molding, and the colors of the sheets constituting the upper surface layer and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com