Device and method for real-time calculation and display of weight of copper foil

A real-time calculation, copper foil technology, applied in the field of electrolytic copper foil, can solve the problems of large-scale scrap, unqualified quality, and failure to find copper foil in time, so as to facilitate the problem of copper foil quality, ensure the quality of copper foil, The effect of omitting the query process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

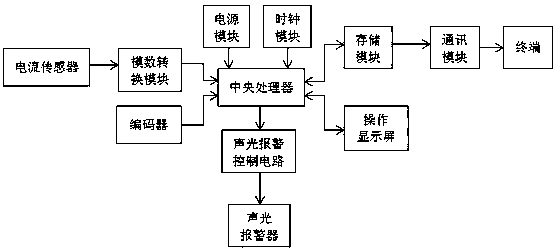

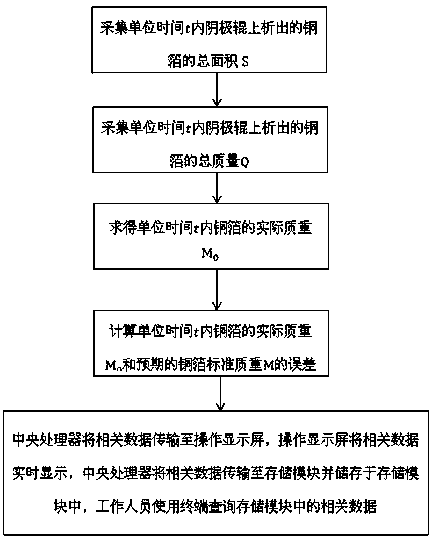

[0031] Such as figure 1 As shown, the present invention includes a central processing unit, a clock module, a current sensor for collecting the output current of the rectifier, an analog-to-digital conversion module, an encoder for collecting the rotation speed of the cathode roller, a storage module, a communication module, an operation display screen, a terminal and Power supply; the input end of the encoder is connected to the shaft of the cathode roller, the input end of the current sensor is connected to the current output end of the rectifier, and the output end of the current sensor is connected to the input end of the analog-to-digital conversion module; the operation display The screen is set on site, and the operation display screen is connected with the central processing unit;

[0032] The central processing unit is connected to the clock module, the input end of the central processing unit is respectively connected to the output end of the analog-to-digital conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com