Water hammer pulse vibration pressurizing tool for long-horizontal-section horizontal well

A technology of pulse vibration and horizontal section, applied in the direction of vibration drilling, etc., can solve the problems of failure to meet the design requirements of the wellbore trajectory, large frictional resistance, poor axial pressure effect, etc., to improve the uniform contact time, axial Strong vibration ability, increase the effect of axial compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

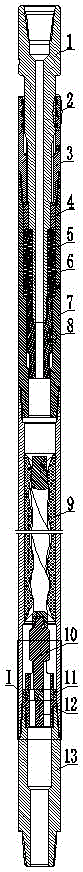

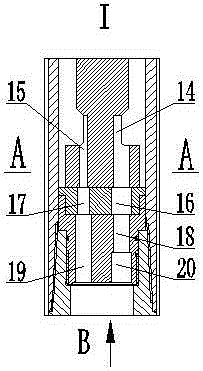

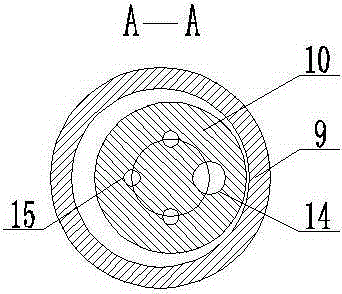

[0016] like Figure 1-Figure 4 As shown, the water shock pulse vibration pressurization tool for horizontal wells with long horizontal section mainly includes transmission shaft 1, lower sealing assembly 2, transmission shaft housing 3, spacer sleeve 4, pressurization assembly housing 5, pressurization Assembly 6, piston sleeve 7, upper sealing assembly 8, power assembly 9, moving valve part 10, wear-resistant valve plate 11, static valve part 12, lower joint 13; transmission shaft housing 3, pressurized assembly housing The body 5, the power assembly 9 and the lower joint 13 are connected by threads sequentially from top to bottom, the transmission shaft 1 is matched with the inner hole of the transmission shaft housing 3, and the upper end is connected with the piston sleeve 7 by threads; the lower sealing assembly 2 is installed on the transmission Shaft 1 and transmission shaft housing 3 on the mating surface; spacer 4 is installed on the upper end of transmission shaft ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com