Novel assembly type ballastless track structure and mounting method thereof

A ballastless track and assembled technology, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of poor maintainability, high cost, and large waste, and achieve the effect of reasonable structure, simple construction, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

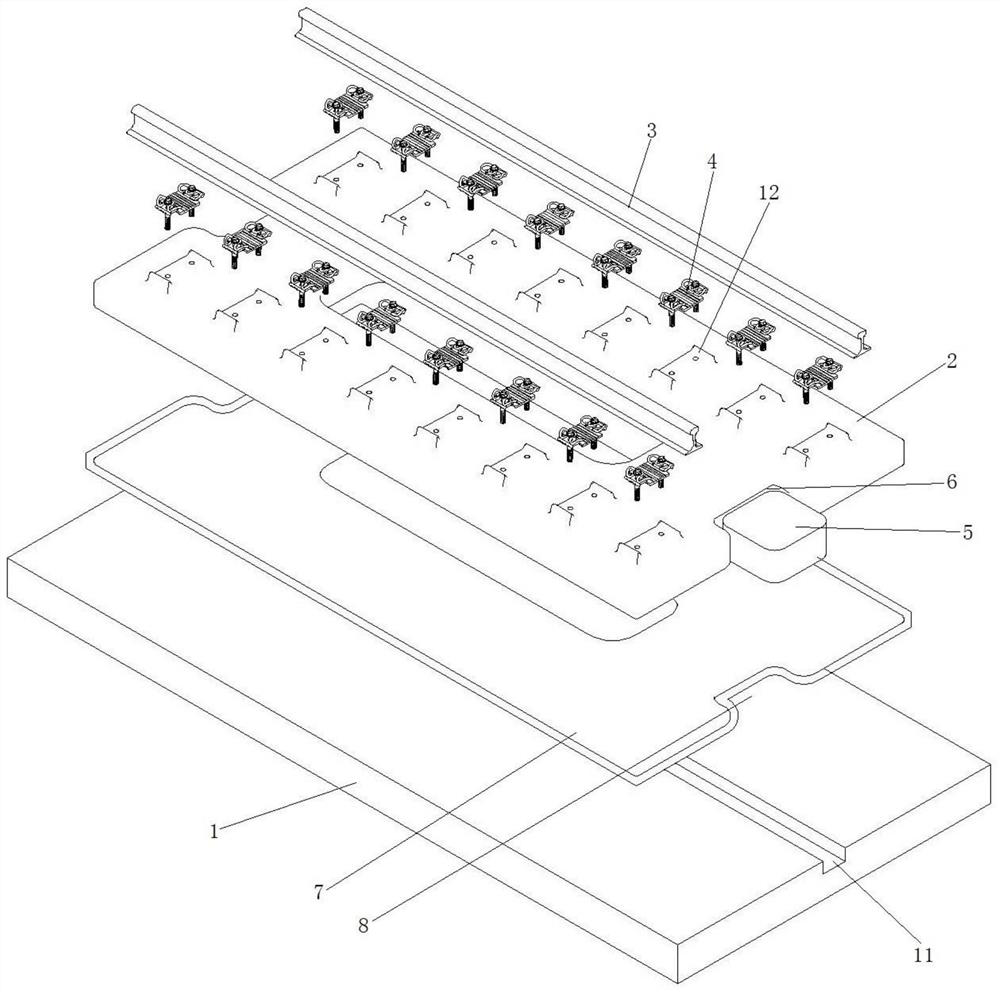

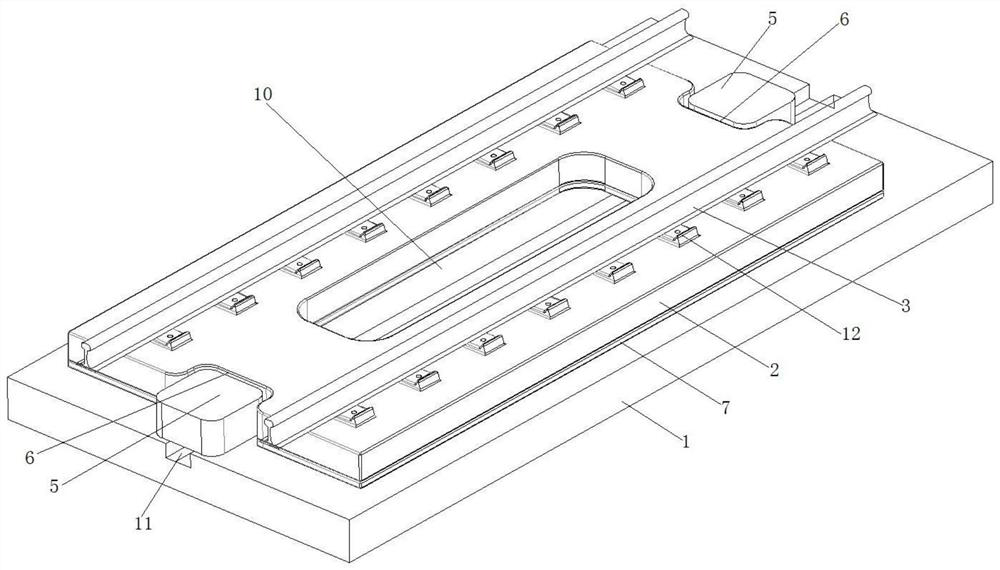

[0045] Such as Figure 1 ~ Figure 4 As shown, a new type of assembled ballastless track structure includes a concrete base 1, on which a plurality of track plates 2 are arranged, and a steel rail 3 is installed on the track plate 2 through a fastener system 4; The upper surface of the concrete base 1 is prefabricated with convex blocks 5 distributed in parallel at equal distances, and several of the convex blocks 5 are arranged along the length direction of the concrete base 1; 5 are provided with the track plate 2 and form a unit, and the outer walls of the two longitudinal ends of the track plate 2 of each unit are respectively provided with draw-in slots 6, and the draw-in slots 6 and the convex stop 5 are set in one-to-one correspondence; the adjacent track plates 2 are independently set and the gap distance is maintained, and an independent detachable adjustment layer is set between the track plate 2 of each unit and the concrete base 1 7. The longitudinal ends of the ad...

Embodiment 2

[0064] The difference between this embodiment and the first embodiment is that an adjustment layer of another structure is provided.

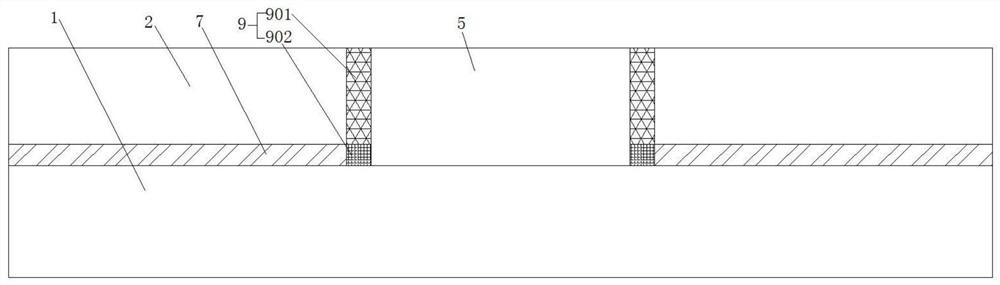

[0065] Such as Figure 5 with Figure 6 As shown, the adjustment layer 7 in each unit is a split structure, including the sub-adjustment layer 701 arranged in half; the distance between the sub-adjustment layers 701 arranged in half is maintained.

[0066] The adjustment layers arranged in this way can be poured separately, and there is no contact between the half adjustment layers 701, forming a horizontal spacing, which can be used as a horizontal drainage ditch 11; avoiding setting up drainage on the concrete base 1 The construction process of the ditch can not only maintain the integrity of the concrete base 1 but also not affect drainage while not affecting the height adjustment and support of the adjustment layer to the track slab 2 .

Embodiment 3

[0068] The difference between the present embodiment and the first embodiment is that another setting method of the convex stopper is provided.

[0069] Such as Figure 7 As shown, the convex block 5 and the concrete base 1 are integrally casted; then grooves are formed around the convex block 5 to merge with the longitudinal drainage ditch to form a complete drainage ditch 11 .

[0070] Such arrangement has not only avoided pouring and forming the convex block 5 separately, but also does not need to set up drainage ditches under the convex block 5, and the construction is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com