Method for preventing blockage through vibration in directional drilling process of horizontal well

A technology for directional drilling and horizontal wells, which is applied in vibration generating devices, earthwork drilling, wellbore/well components, etc., which can solve the problems of high adhesion, difficulty in lifting, sticking and other problems on the lower well wall, so as to avoid sticking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

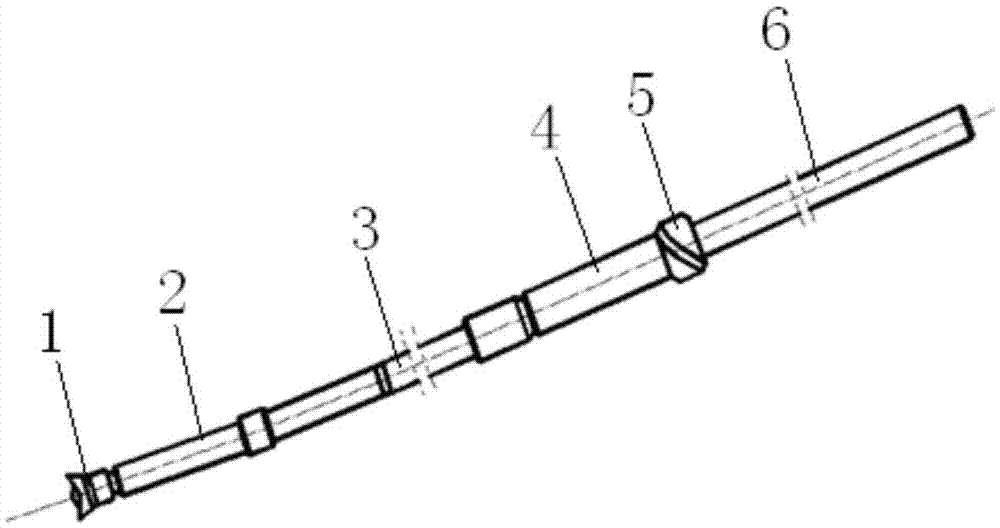

[0008] Such as figure 1 As shown, the deflection drilling tool assembly for horizontal wells is composed of drill bit 1, power drilling tool 2, drill collar, drill pipe 3 and drilling tool 6. It is a vibration and anti-seize method that can be used in the process of directional drilling in horizontal wells. The steps of the method are as follows: install one or more sets of vibratory tools 4 on the upper part of the drill collar and drill pipe 3 in the deflection drilling tool assembly of the horizontal well, and install an anti-seize centralizer 5 on the upper part of the vibratory tool 4 .

[0009] It can be understood that the above specific descriptions of the present invention are only used to illustrate the present invention and are not limited to the technical solutions described in the embodiments of the present invention. Those of ordinary skill in the art should understand that the present invention can still be modified or Equivalent replacements to achieve the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com