Self-locking drill rod capable of rotating forwards and backwards

A forward-reversing, self-locking technology, applied in the field of mining machinery, can solve the problems of reducing the efficiency of automatic drilling rig construction, cumbersome loading and unloading process, manual installation, etc., to improve the efficiency of automatic construction, simple structure, enhanced slag discharge and unloading pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

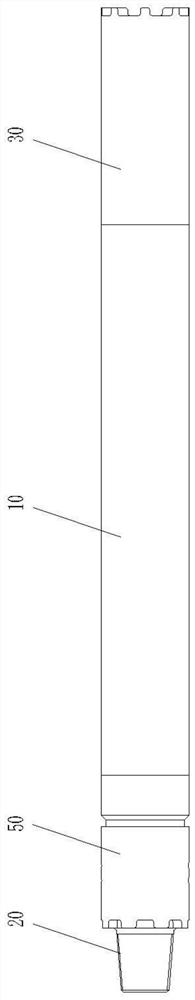

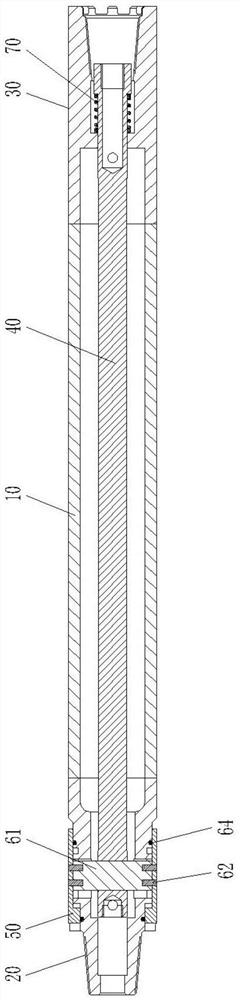

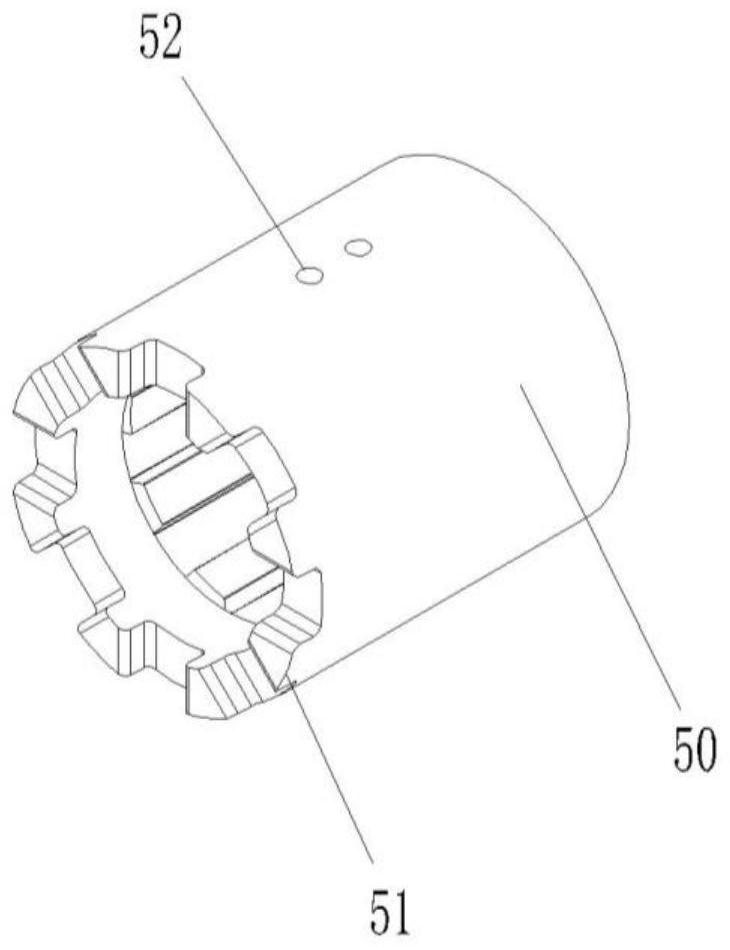

[0033] As shown in the figure: the self-locking reversible drill pipe of this embodiment includes a rod body 10, a male joint 20 connected to both ends of the rod body, a female joint 30 for threaded connection with the male joint, a mandrel 40 and a sliding sleeve 50. The threaded connection between the male joint and the female joint here refers to the connection between the male joint of a drill pipe and the female joint of an adjacent drill pipe, and there is no direct connection between the male joint and the female joint on the same drill pipe; the rod body , the male joint and the female joint are hollow structures to form a fluid channel that communicates with each other in the axial direction and communicates with the outside world. The mandrel is sleeved in the rod body and has a driving force that slides axially backward. The driving force can be passed through the elastic member or The drive equipment provides that the sliding sleeve axially seals the sliding sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com