Control system and control method of logging drilling sidewall coring tool

A wall corer and control system technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of not being able to issue drilling withdrawal instructions in time, damaging downhole instruments, and unlocking cards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

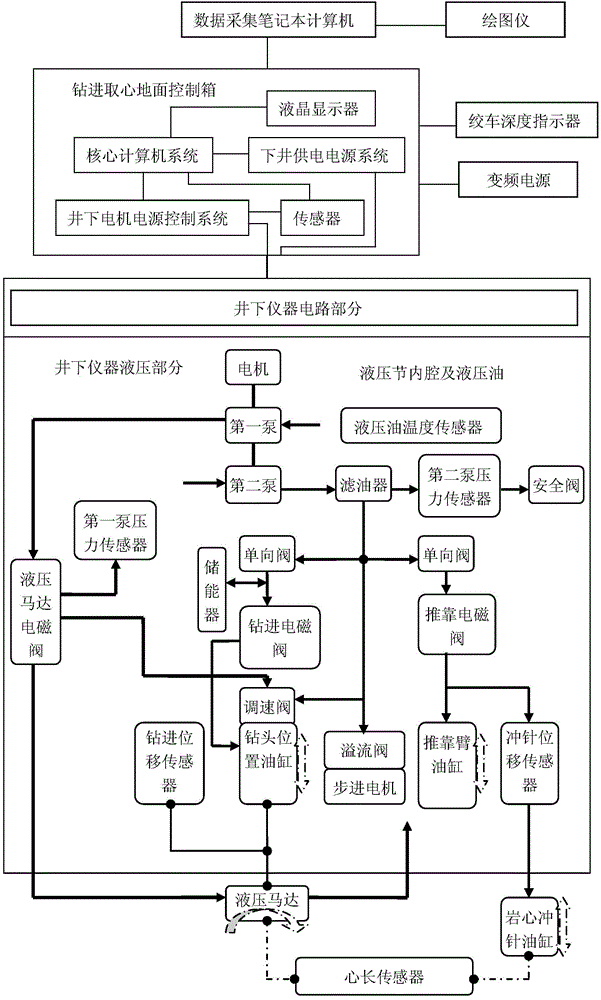

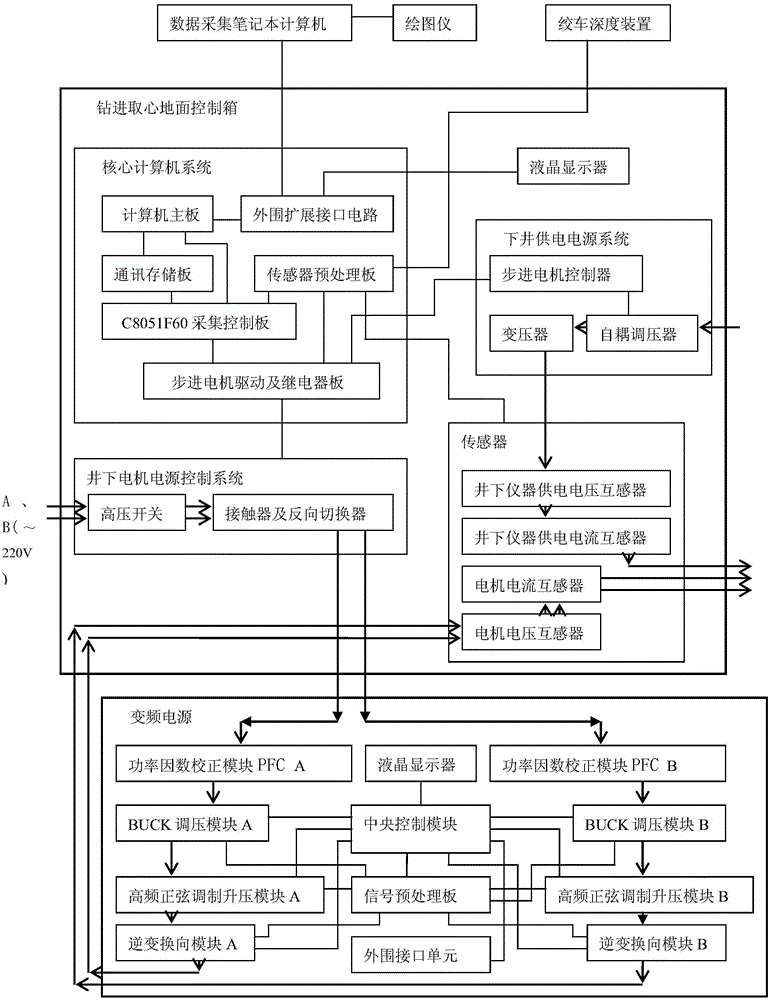

[0062] like figure 1 As shown, the control system of the well logging drilling type sidewall coring device of the present invention includes a data acquisition notebook computer for the real-time recording function of coring data; a plotter for the paper recording function of coring data; Frequency conversion power supply for downhole instrument motor power supply; drilling and coring surface control box for signal processing and data acquisition, as well as downhole instrument status control and power supply; The drawworks depth device of the movement signal; the drilling and coring ground control box obtains the depth, movement direction and speed data of the downhole instrument in the wellbore according to the received movement signal, as real-time information of other coring data. It also includes the hydraulic part of the downhole instrument used for drilling sidewall coring operation and energy transmission; the circuit part of the downhole instrument used for detecting ...

Embodiment approach 2

[0070] When the control system of the logging drilling type borehole wall coring device described in the present invention is working, the coring is completed under the control of the ground control box for drilling and coring, and the method of automatically adjusting the working voltage of the solenoid valve. Such as image 3 as shown,

[0071] First, the ground control box supplies power to complete the initialization process; then the ground control box sets the working safety voltage of the solenoid valve of the downhole instrument; after that, the ground control box supplies power to the downhole instrument, and the circuit part of the downhole instrument completes the initialization process; the downhole instrument uploads the working status to the ground The control box and the ground control box query the working voltage of the solenoid valve in the downhole instrument, and start the process of automatically adjusting the working voltage of the solenoid valve; when th...

Embodiment approach 3

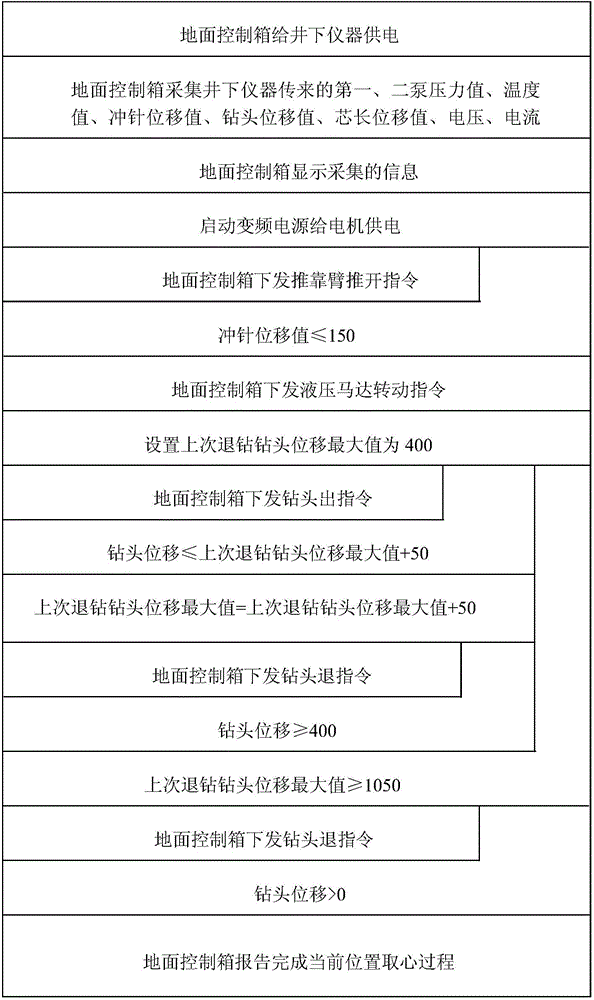

[0073] When the control system of the logging drilling type borehole wall coring device described in the present invention works, the coring is completed by the control of the ground control box for drilling and coring, such as Figure 4 As shown, its overall method steps are as follows.

[0074] First, after the ground control box is powered on, set the maximum safe working current of the motor of the downhole instrument, the maximum power value of the system, the maximum safe working current variation of the motor, the minimum drilling displacement variation ΔS per unit time of the drill bit, and the maximum displacement of the drill bit Smax, etc., the ground control box supplies power to downhole instruments and establishes communication with downhole instruments; then, the ground control box collects the motor operating current, first pump pressure value, and drill bit drilling displacement value instrument status data uploaded by downhole instruments; After the start, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com