Water-based drilling fluid lubricant composition and preparation method thereof

A lubricant composition, water-based drilling fluid technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of easy desorption, scratching, accelerated wear and corrosion, and adsorption of lubricating film layers on metal surfaces It can reduce the probability of differential pressure sticking, increase the adsorption, and enhance the strength of the filter cake.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

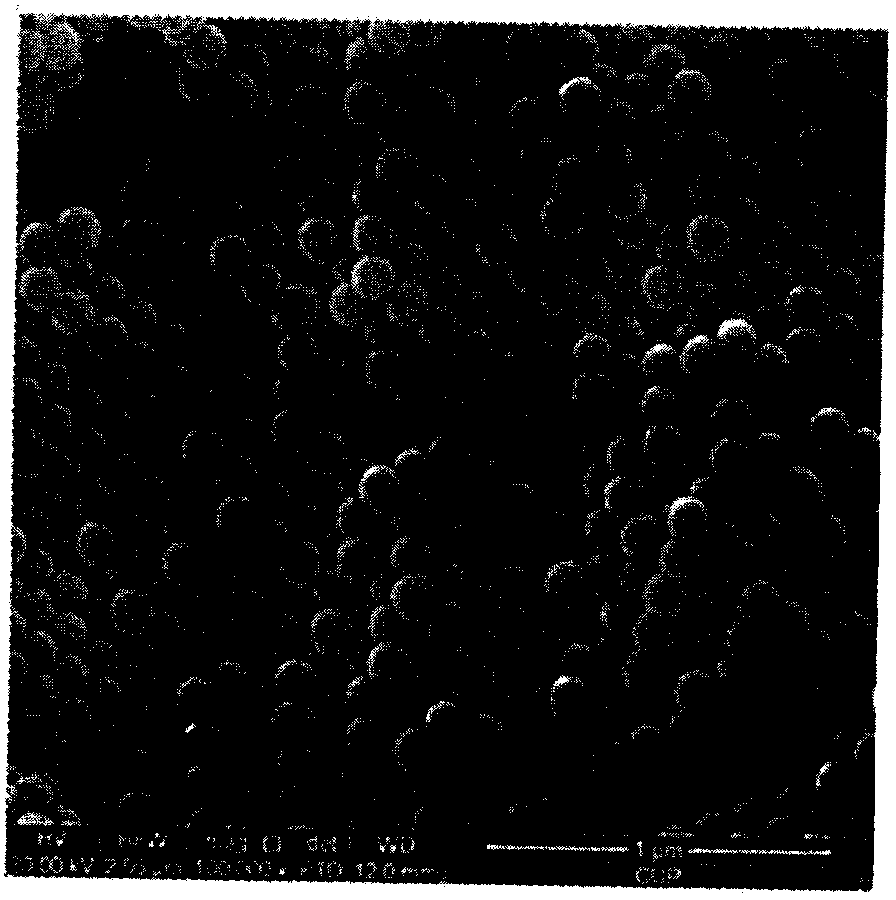

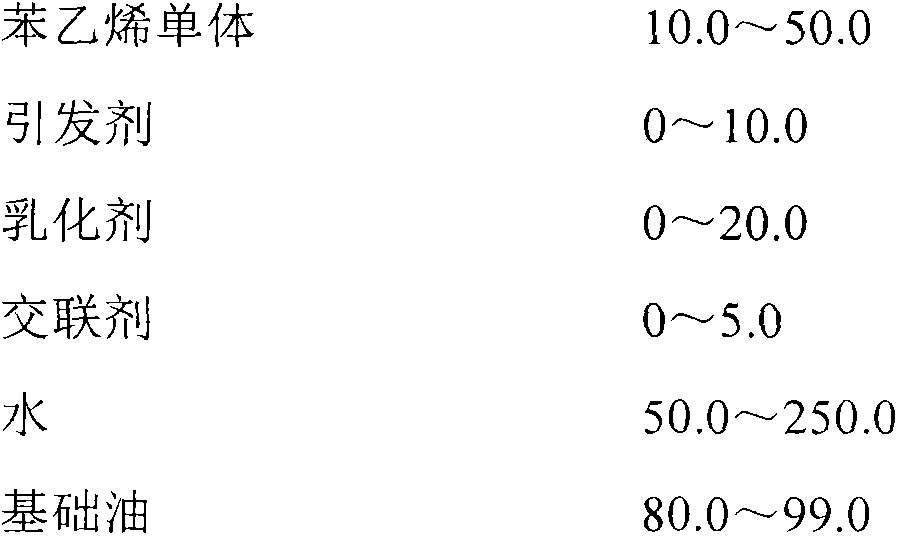

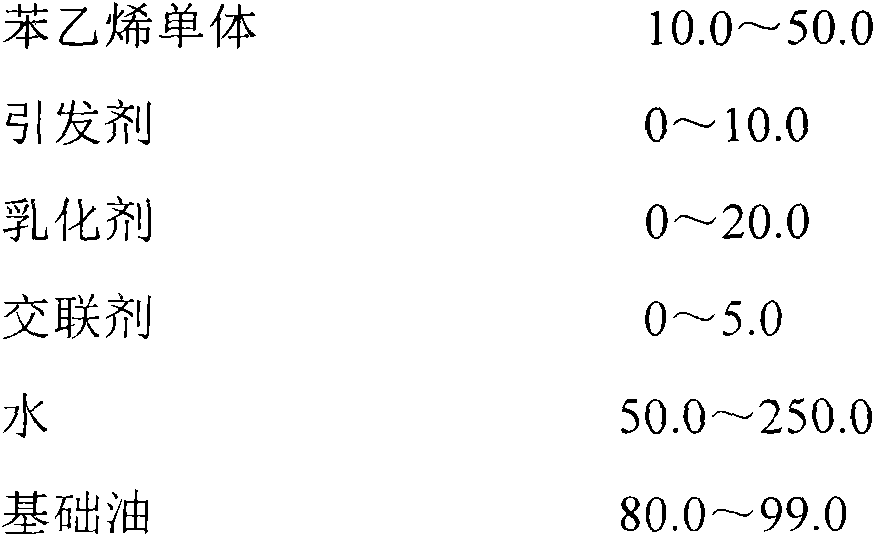

[0024] The water-based drilling fluid lubricant composition of the present invention is a stable emulsion system, the appearance is a milky white emulsion, the particle diameter is small, and the average particle diameter is between 10-70nm. The parts by mass of each component are as follows:

[0025]

[0026] The described water-based drilling fluid lubricant composition is prepared according to the following steps: first, the styrene monomer is sequentially rinsed with 8% NaOH solution and distilled water, and after being neutralized by pH test paper, the obtained product is dried with anhydrous sodium sulfate The purified product is then distilled under reduced pressure to obtain styrene monomer suitable for polymerization purity; secondly, the extracted mass parts are 10.0 to 50.0 parts of styrene monomer and 50.0 to 250.0 parts of deionized water, and are mixed with the initiator at room temperature The emulsifier is 0-10.0 parts of sodium dodecylbenzenesulfonate, and ...

Embodiment 2-6

[0028] The rheological property experiment of the prepared water-based drilling fluid lubricant composition according to embodiment 1 is as follows:

[0029] Preparation of the base slurry: add 5g of Na-montmorillonite to 100mL of water, stir at a high speed of 5300rpm on a high-speed mixer for 20min, and then airtightly age at room temperature for 24h to obtain a Na-montmorillonite base slurry with a soil content of 5%. .

[0030] Rheological properties test:

[0031] Add the pre-prepared water-based drilling fluid lubricant composition according to the mass fraction of 0, 0.2%, 0.5%, 0.8%, and 1.2% into the prepared drilling fluid base slurry, stir at high speed with a high-speed mixer for 5 minutes, and then pour In the measuring cup of the six-speed viscometer, make the liquid level equal to the scale line of the outer cylinder of the viscometer. Set the speed of the viscometer at 600, 300, 200, 100, 6 and 3rpm respectively, and wait for the dial to stabilize, then read ...

Embodiment 7-10

[0038] Preparation method is with embodiment 1, and difference is:

[0039] The prepared water-based drilling fluid lubricant composition selects octadecyltrimethylammonium bromide as an emulsifier, and the pre-prepared water-based drilling fluid lubricant composition is 0.2%, 0.5%, 0.8% according to the mass fraction , 1.2% was added in the prepared drilling fluid base slurry, and the rheological performance experiment of the prepared water-based drilling fluid lubricant composition was carried out in the same manner as in Examples 2-6, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com