Preparation method of oilless lubricant condom having a single graphene-fluoride composite latex lubricating side

A technology of fluorinated graphene and composite latex, which is applied in medical science, surgery, etc., can solve the problems of reduced lubricating performance of graphite, and achieve the effects of enhanced lubricity, stable properties, and convenient industrial production and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

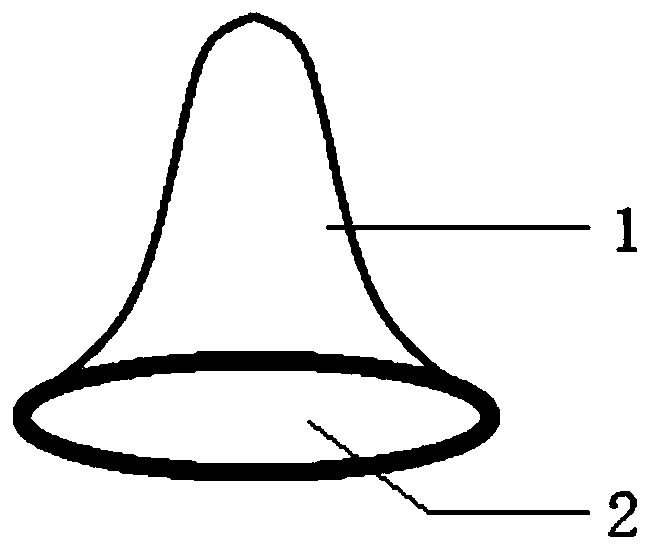

Image

Examples

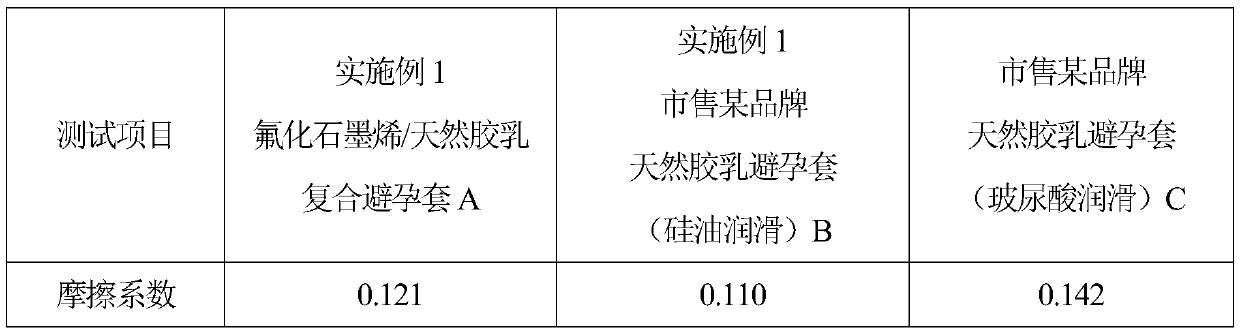

Embodiment 1

[0024] In the present embodiment, the preparation method of the oil-free condom that one side is the lubricating surface of fluorinated graphene composite latex is as follows:

[0025] Select 10 g of fluorinated graphene with a thickness of 90% normally distributed in layers 1 to 5, the atomic ratio of fluorine to carbon is 1:2, and the sheet diameter / thickness ratio is 1200. Soak it with concentrated sulfuric acid (concentration: 98wt%) and ferrate solution (concentration: 80wt%) for 2 hours at a mass ratio of 1:100, wherein the mass ratio of concentrated sulfuric acid: ferrate is 10:1. Then washed with water until neutral, vacuum freeze-dried into powder.

[0026] Put the oxidized freeze-dried fluorinated graphene powder into 1000g concentration of 1wt% polyvinylpyrrolidone (PVP) aqueous solution and sonicate for 1 hour, its effect is: further coat and modify the surface of fluorinated graphene; then filter to obtain the surface The treated fluorinated graphene powder is di...

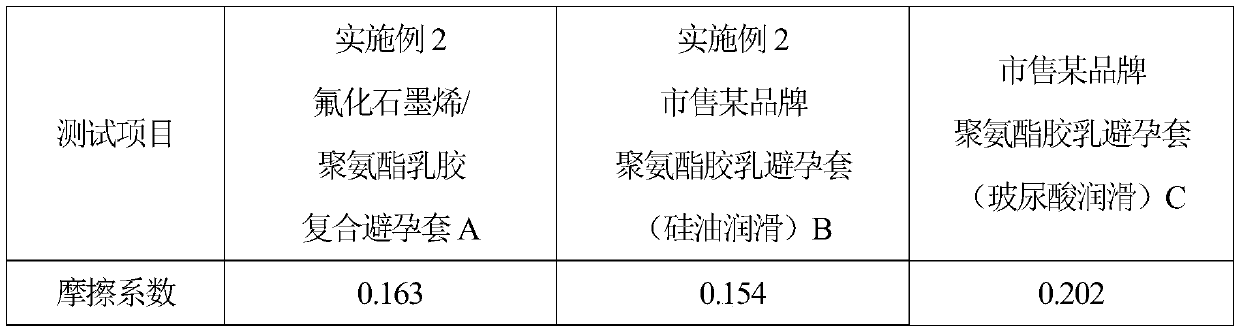

Embodiment 2

[0033] In the present embodiment, the preparation method of the oil-free condom that one side is the lubricating surface of fluorinated graphene composite latex is as follows:

[0034]Select 10 g of fluorinated graphene whose thickness is 90% distributed in layers 1 to 5, the atomic ratio of fluorine to carbon is 1:1, and the sheet diameter / thickness ratio is 1600. Soak it with hydrogen peroxide and ferrate solution (concentration: 80wt%) for 2 hours at a mass ratio of 1:100, wherein the mass ratio of hydrogen peroxide: ferrate is 10:1. Then washed with water until neutral, vacuum freeze-dried into powder.

[0035] Put the oxidized freeze-dried fluorinated graphene powder into 1000g concentration of polyvinylpyrrolidone (PVP) aqueous solution for 1 hour, then filter to obtain surface-treated fluorinated graphene powder and disperse it into 1000g of pure water , forming a composite aqueous dispersion with a dispersion stability greater than 24 hours. Then, the composite aqueo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com